Self-reactive protective paint on steel surface and its application

A steel surface and protective coating technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as personal health threats, low work efficiency, and environmental pollution, and achieve the effects of easy industrial implementation, reduced implementation costs, and reduced environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of iron and steel surface self-reactive protective paint component is as follows: oxalic acid 25g / L, molybdic acid 25g / L, ascorbic acid 25g / L and citric acid organic acid 25g / L, EDTA disodium 25g / L, sodium gluconate 25g / L, Sodium fluoride 5g / L, hydroxylamine hydrochloride 5g / L, sodium lauryl sulfate 1g / L, activated nano-alumina micropowder 100g / L, silicon dioxide micropowder 100g / L, and the balance is water. Mix and stir the above components evenly to obtain the final coating. Manual coating or mechanical spraying to the untreated mildly corroded steel substrate surface to obtain protective coating example 1, which can protect the metal surface from wear resistance, moisture resistance, oxidation and corrosion resistance.

Embodiment 2

[0038] A kind of iron and steel surface self-reactive protective paint component is as follows: oxalic acid 25g / L, molybdic acid 30g / L, ascorbic acid 40g / L and citric acid organic acid 50g / L, EDTA disodium 40g / L, sodium gluconate 30g / L, Sodium fluoride 10g / L, hydroxylamine hydrochloride 7g / L, sodium lauryl sulfate 1g / L, sodium dodecylbenzenesulfonate 2g / L, activated nano-alumina fine powder 150g / L, silicon dioxide fine powder 100g / L L, the balance is water. Mix and stir the above components evenly to obtain the final coating. Manual coating or mechanical spraying to the untreated moderately corroded steel substrate surface to obtain protective coating example 2, which can protect the metal surface from wear resistance, moisture resistance, oxidation and corrosion resistance.

Embodiment 3

[0040] A kind of iron and steel surface self-reactive protective paint component is as follows: oxalic acid 50g / L, molybdic acid 40g / L, ascorbic acid 30g / L and citric acid organic acid 25g / L, EDTA disodium 30g / L, sodium gluconate 40g / L, Potassium fluoride 10g / L, hydroxylamine hydrochloride 8g / L, sodium dodecylsulfonate 2g / L, ethoxylated alkyl sodium sulfate 1g / L, activated nano-alumina powder 100g / L, silicon dioxide powder 150g / L, the balance is water. Mix and stir the above components evenly to obtain the final coating. Manual coating or mechanical spraying to the surface of untreated moderately corroded steel substrates to obtain protective coating example 3, which can protect the metal surface from wear resistance, moisture resistance, oxidation and corrosion resistance.

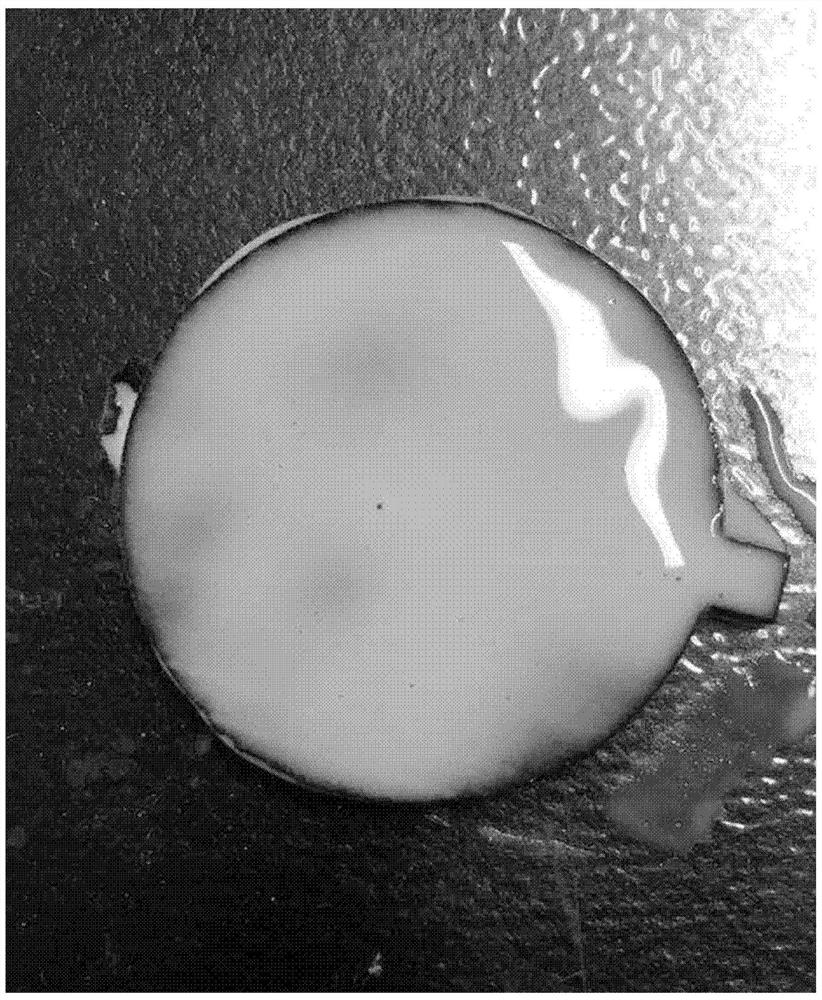

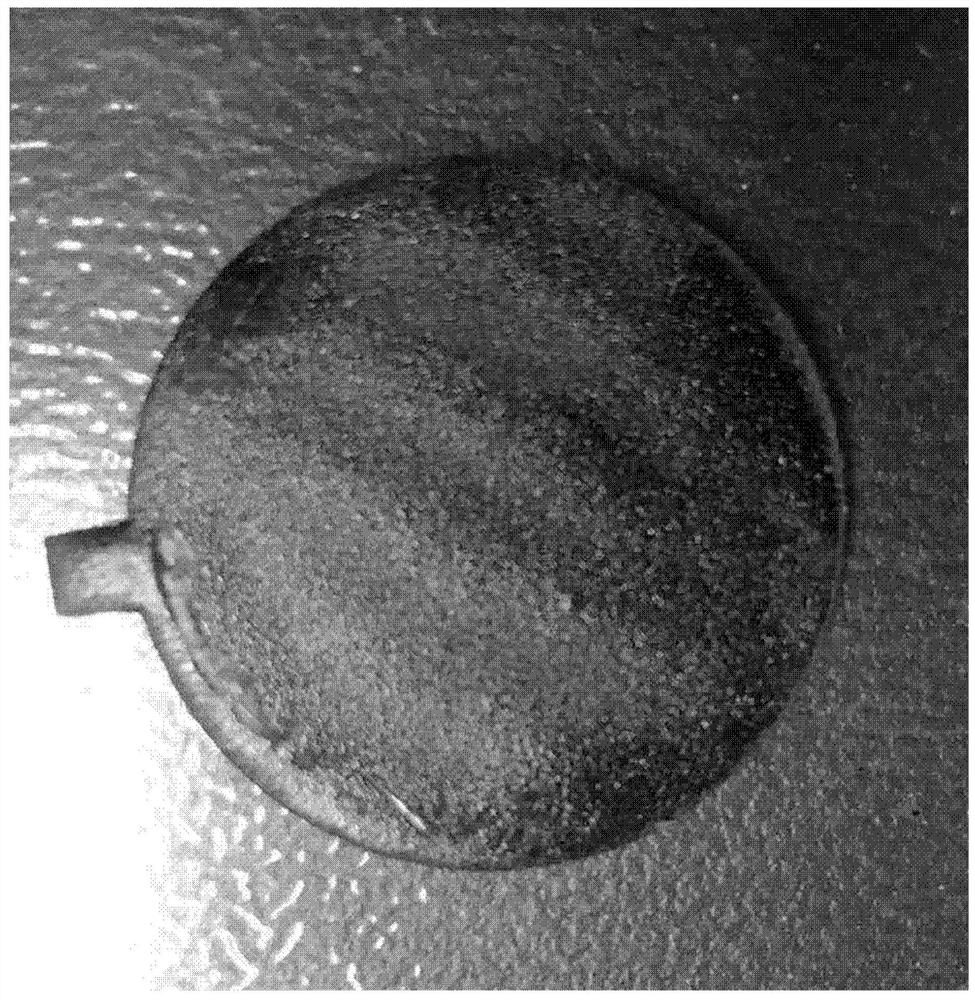

[0041] Such as Figure 1-3 As shown, the self-reactive protective coating of embodiment 3 is used to coat or mechanically spray the untreated moderately corroded steel substrate surface, and the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com