Coating slurry for current collector of lithium ion battery as well as current collector and preparation method thereof

A lithium-ion battery and current collector technology, applied in the field of lithium-ion batteries, can solve problems such as increased contact internal resistance and unsatisfactory self-discharge, and achieve the effects of improved performance, strong repeatability, and strong processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

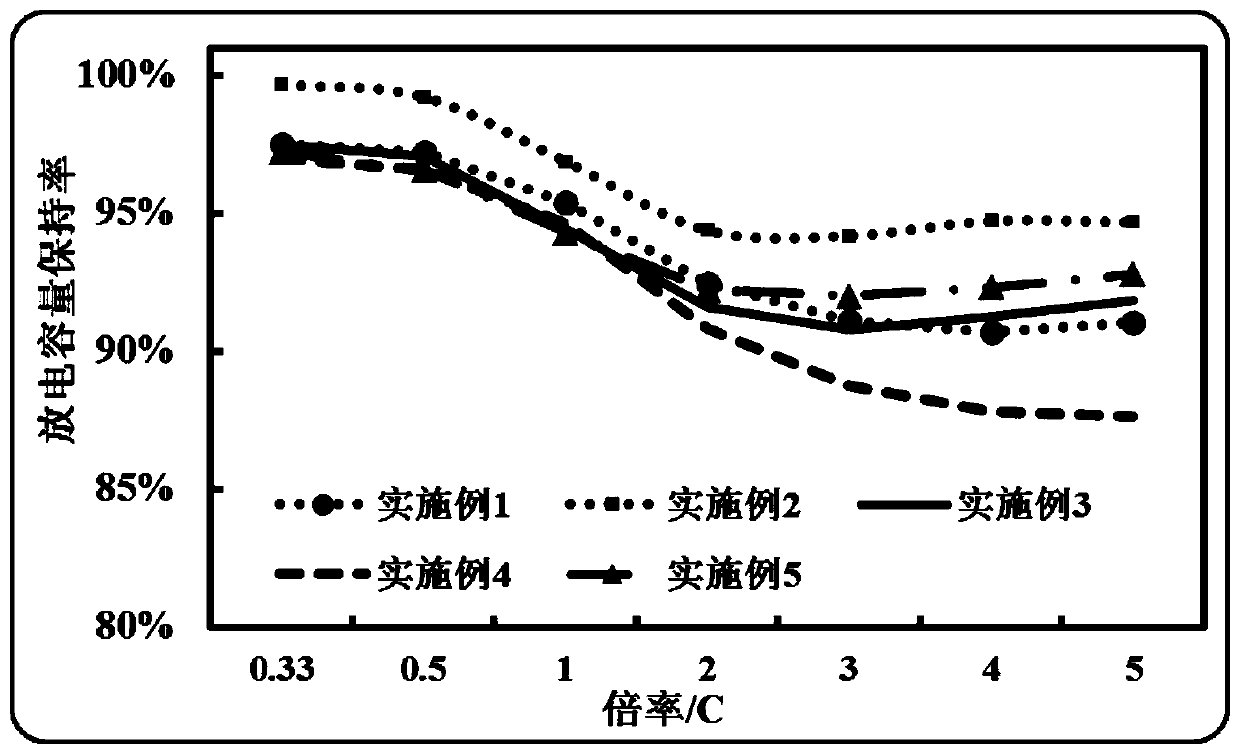

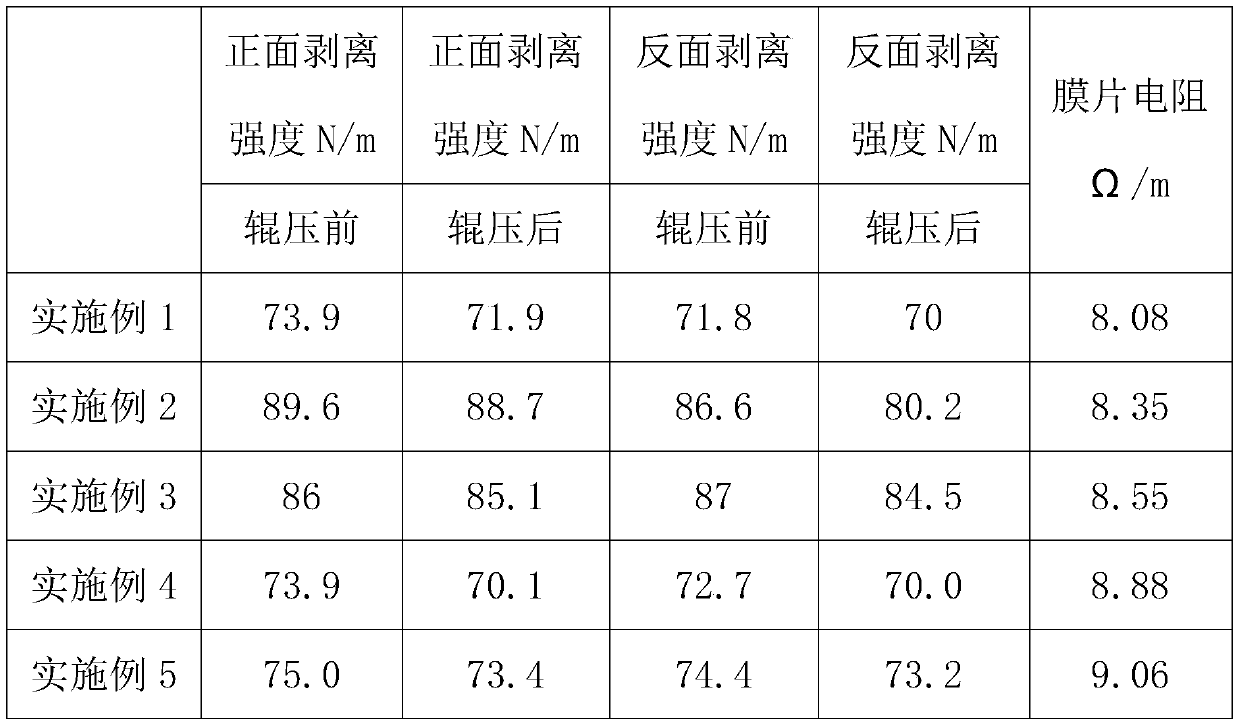

Examples

Embodiment 1

[0036] The preparation method of the coating slurry for the current collector of the lithium ion battery proposed by the present invention comprises the following steps:

[0037] S1. Add CMC and deionized water to the disperser at a mass ratio of 5:95, control the temperature of the disperser to 25°C, and the speed to 1800rmp, and disperse for 4 hours to obtain an anti-sedimentation dispersion;

[0038] S2. According to the percentage by weight, take 15% anti-sedimentation dispersion liquid and 1% SiC polyether-modified silicone oil surfactant and add them to the disperser, keep the temperature of the disperser at 25°C and the speed of 1200rmp, disperse for 2 hours, and then add 1.5 % graphene and 74% deionized water, rotating speed 2800rmp, disperse for 2 hours, add 1.5% carbon nanotubes, rotating speed 2800rmp, disperse for 1 hour, add 2% conductive carbon black, rotating speed 2800rmp disperse for 1 hour to obtain black slurry; Add 5% water-based acrylonitrile multi-polymer...

Embodiment 2

[0041] The preparation method of the coating slurry for the current collector of the lithium ion battery proposed by the present invention comprises the following steps:

[0042] S1. Add CMC and ethanol aqueous solution into the disperser according to the mass ratio of 5:95, control the temperature of the disperser to 25°C, and the rotational speed to 1800rmp, and disperse for 2 hours to obtain an anti-sedimentation dispersion; wherein, ethanol and water in the ethanol aqueous solution The volume ratio is 1:1;

[0043] S2. According to the mass percentage, take 20% anti-sedimentation dispersion liquid and 1% non-ionic fluorocarbon surfactant and add them to the disperser, keep the temperature of the disperser at 25°C and the speed of 1200rmp, disperse for 2 hours, and then add 1.5% graphite Alkene and 71.2% ethanol aqueous solution, wherein, the volume ratio of ethanol and water in the ethanol aqueous solution is 1:1, the rotational speed is 2800rmp, disperse for 2 hours, add 1....

Embodiment 3

[0046] The preparation method of the coating slurry for the current collector of the lithium ion battery proposed by the present invention comprises the following steps:

[0047] S1. Add CMC and isopropanol aqueous solution into the disperser at a mass ratio of 5:95, control the temperature of the disperser at 25°C, and the rotational speed at 1800rmp, and disperse for 3 hours to obtain an anti-sedimentation dispersion; among them, the isopropanol aqueous solution , the volume ratio of isopropanol to water is 1:1;

[0048] S2. According to the mass percentage, take 20% anti-sedimentation dispersion liquid and 1% non-ionic fluorocarbon surfactant and add it to the disperser, keep the temperature of the disperser at 25°C and the speed of 1200rmp, disperse for 2 hours, and then add 1% graphite Alkene and 69.8% isopropanol aqueous solution, wherein, in the isopropanol aqueous solution, the volume ratio of isopropanol to water is 1:1, disperse at 2800rmp for 2 hours, add 2% carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com