Power collecting plate assembly

A board assembly and electricity harvesting technology, which is applied in the direction of electrical components, circuits, fuel cells, etc., can solve the problems of heat dissipation of electricity harvesting boards, achieve good electrical conductivity, medium corrosion resistance and heat dissipation performance, and overcome the problems of poor medium corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

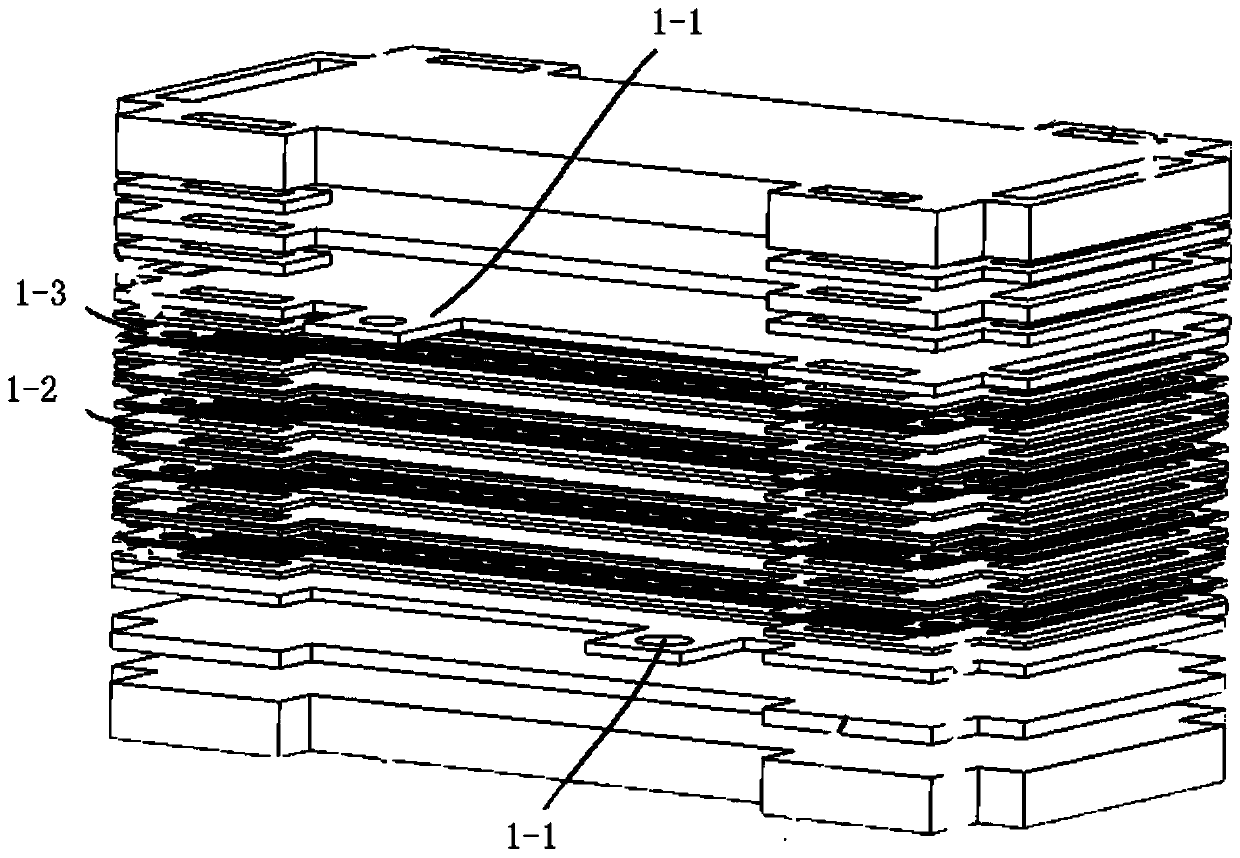

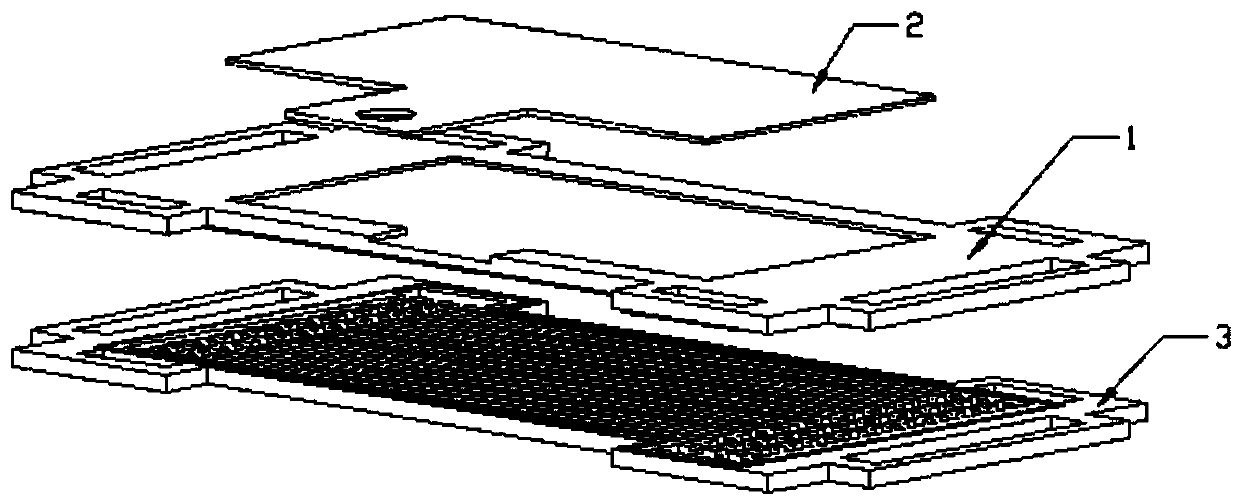

[0033] see in conjunction Figure 3-6 As shown, a power harvesting board assembly provided by an embodiment of the present invention is installed in a fuel cell, including: a power harvesting board for collecting and exporting current in a fuel cell; a heat sink 3 installed on a The electricity collecting board is used to absorb the heat of the electricity collecting board.

[0034] The power collecting board assembly of the present invention improves the heat dissipation performance of the power collecting board by installing the cooling plate 3 on the power collecting board.

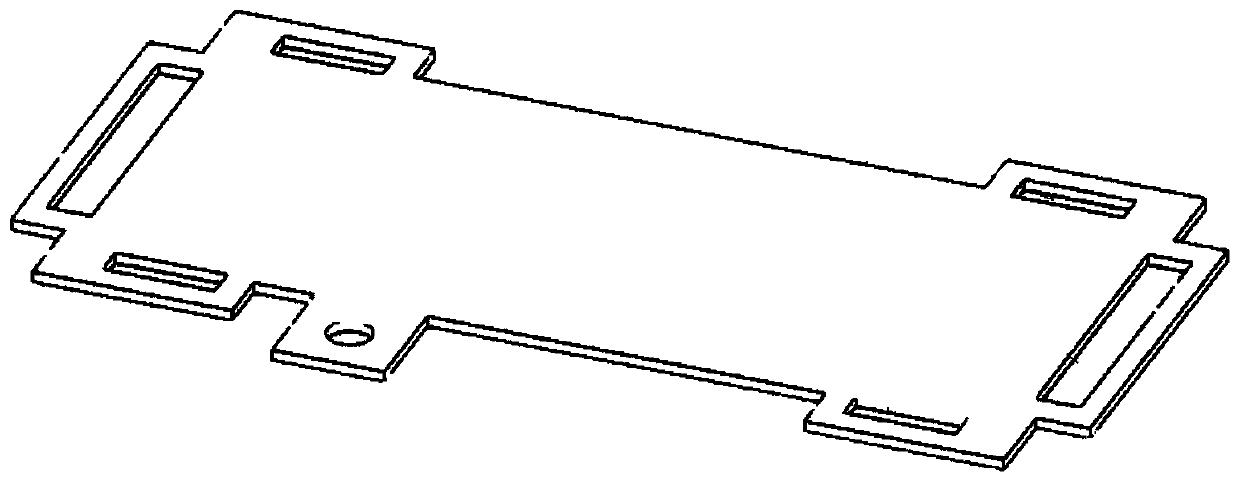

[0035] In this embodiment, the preferred power mining board includes: base plate 1, base plate 1 is made of corrosion-resistant materials; panel 2, panel 2 is installed on the base plate 1, used to collect the current in the fuel cell and export the current ; The panel 2 and the cooling plate 3 are arranged on both sides of the bottom plate 1 respectively.

[0036] This implementation adopts the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com