Composite electrolyte for pre-lithiation of lithium battery and application of composite electrolyte

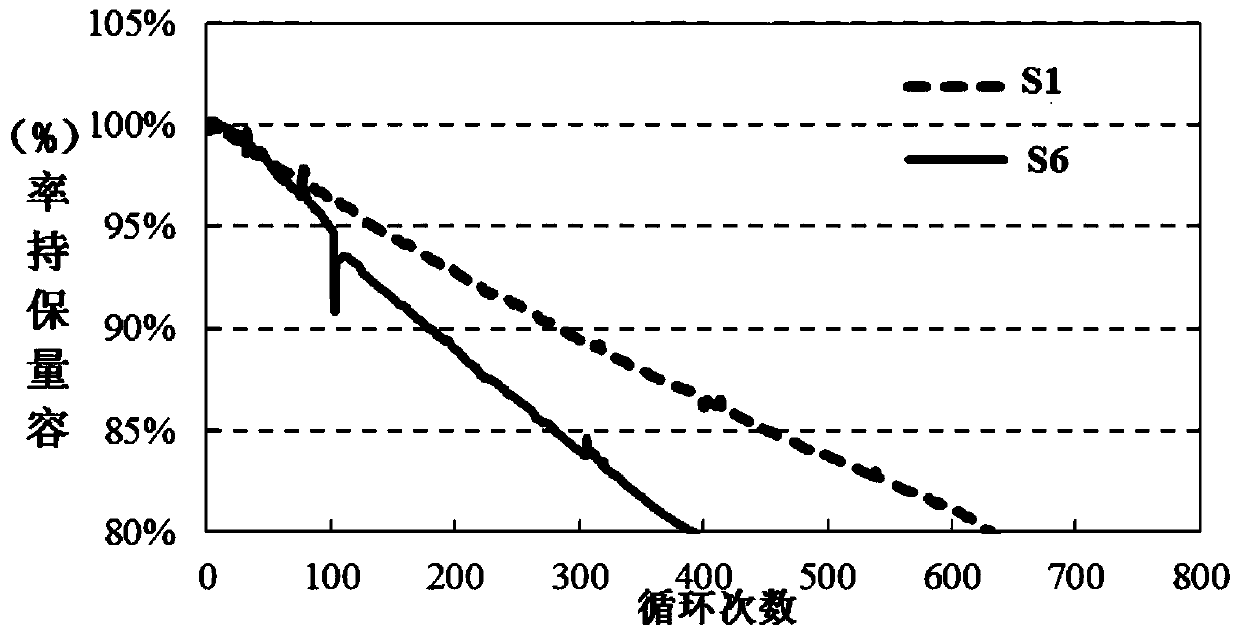

A composite electrolyte and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of lithium metal safety hazards, low evaporation efficiency, and lack of promotion, and achieve improved cycle life and energy density, battery accuracy, and first coulomb. Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

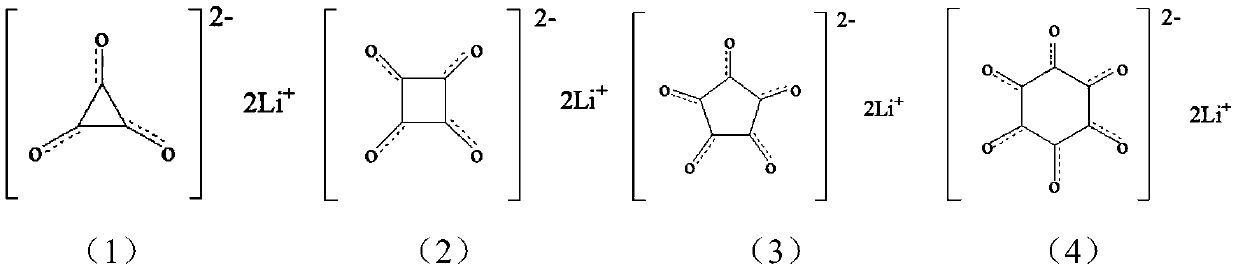

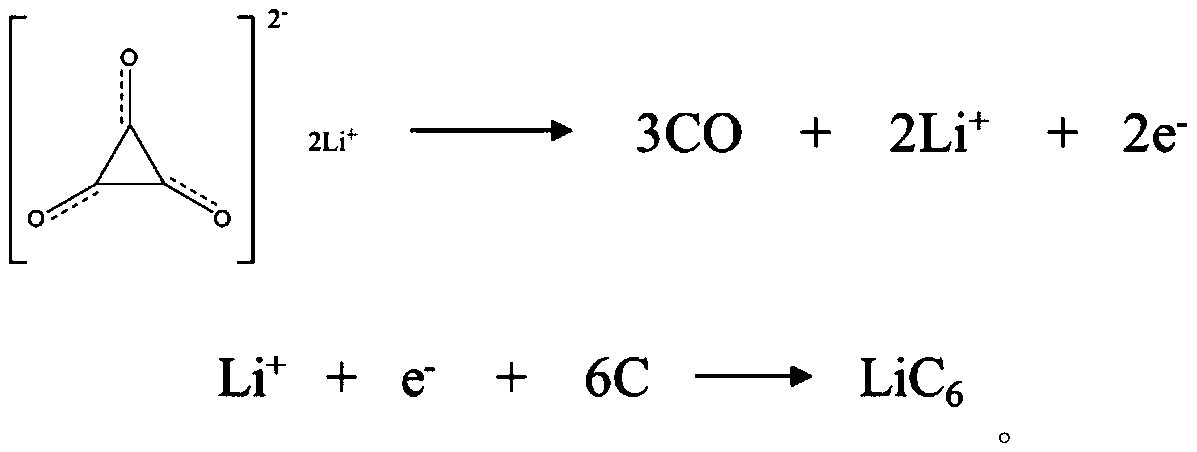

[0030] A composite electrolyte solution for pre-lithiation of a lithium battery. In a nitrogen atmosphere, 0.49 g of dihydroxycyclopropenone dilithium salt is added to the electrolyte solution to dissolve it, and the composite electrolyte solution containing 1M additives is prepared.

Embodiment 2

[0032] A composite electrolyte solution for pre-lithiation of a lithium battery. In a nitrogen atmosphere, 0.51 g of dilithium oxalate is added to the electrolyte solution to dissolve it, and the composite electrolyte solution containing 1M additives is prepared.

Embodiment 3

[0034] A composite electrolyte solution for pre-lithiation of a lithium battery. In a nitrogen atmosphere, 0.49 g of polydimethylhydrazide dilithium salt is added to the electrolyte solution to dissolve it, and the composite electrolyte solution containing 1M additives is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com