Micro-fluidic chip for geological process chemical corrosion study and making method

A microfluidic chip and process chemistry technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problem of hindering multiphase flow movement and material exchange process, Newton rings appearing on the glass surface, chip Reduced production yield and other issues, to achieve the effect of convenient mass production, short preparation time, and high channel production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail through examples below, but the protection scope of the present invention is not limited to the following description. Unless otherwise specified, the experimental methods used are conventional experimental methods; the reagents and materials used can be obtained through commercial channels.

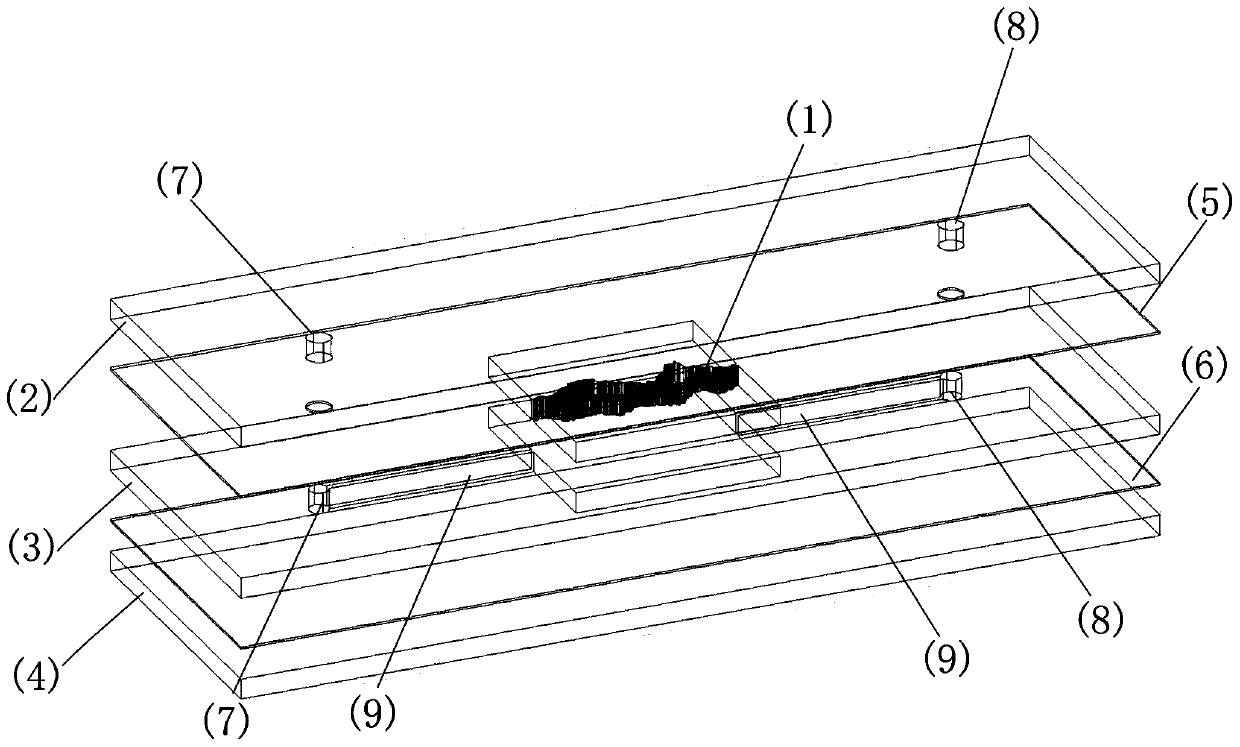

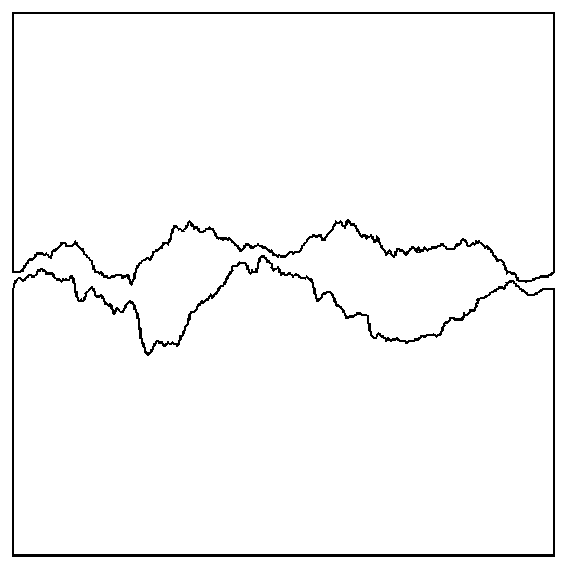

[0019] The microfluidic chip used for chemical dissolution research in geological processes provided by the present invention includes a microfluidic chip main body 1 with microchannels arranged in parallel horizontally, an upper base layer 2, a middle base layer 3, a lower base layer 4, and an upper base layer Layer 5, lower adhesive coating 6; upper base layer 2, upper adhesive coating layer 5, middle base layer 3, lower adhesive layer 6 and lower base layer 4 are arranged horizontally parallel to chip main body 1 from top to bottom, and middle base layer 3 runs through horizontally The chip main body 1 is divided into the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com