Three-section ceramic valve

A three-stage, ceramic valve technology, used in sliding valves, valve details, valve devices, etc., can solve problems such as poor impact resistance, overcome brittleness, improve sealing effect, and facilitate rapid assembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

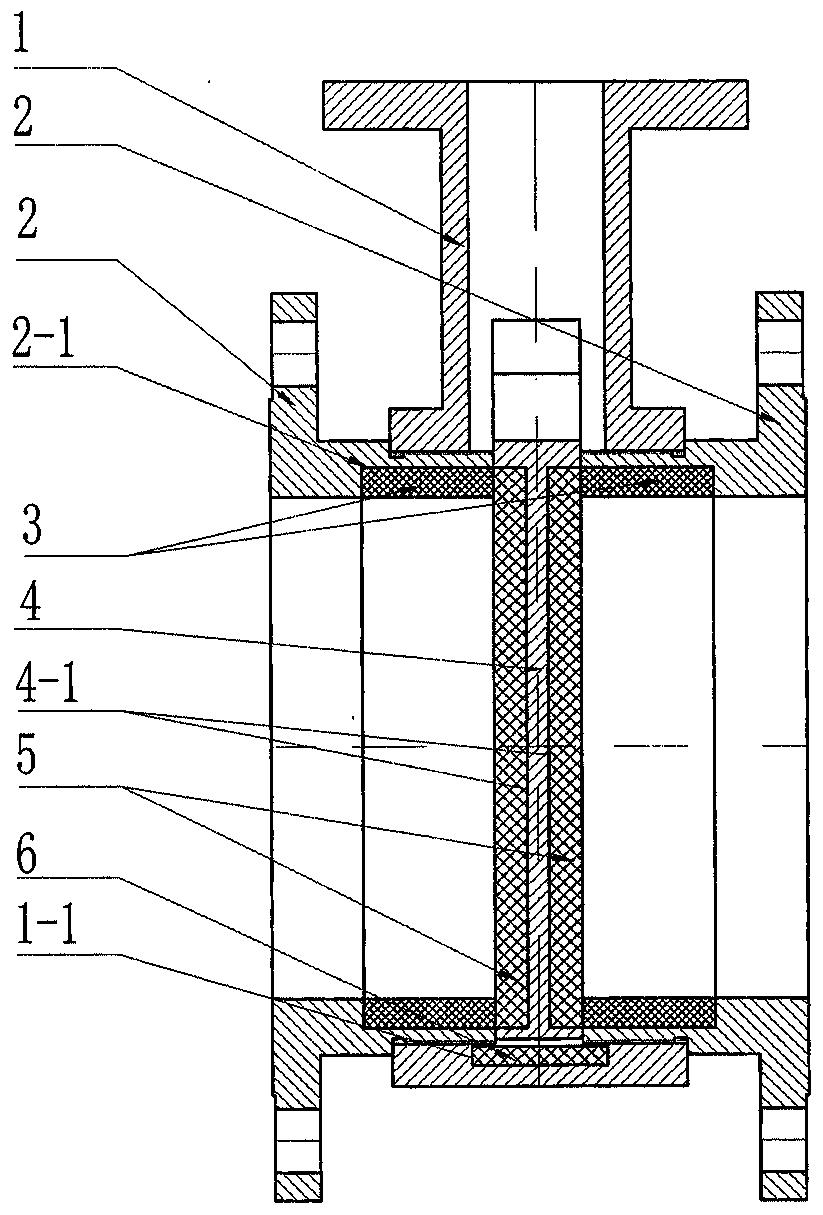

[0022] Such as figure 1 As shown, a three-section ceramic valve in Embodiment 1 includes a three-section combined valve body and a ceramic gate inserted in the flow channel of the valve body; the ceramic gate is composed of a gate base (4) and an embedded The gate ceramics (5) installed in the gate grooves (4-1) on both surfaces of the gate base body are composed of (the ceramic gate is a self-sealing parallel gate, and the two sealing surfaces are parallel to each other, that is, the The gate ceramics (5) are embedded in the gate grooves (4-1) on both surfaces of the gate base (4), which can resist the erosion and wear of the gate base by the medium when the valve adjusts the flow rate); The combined valve body is composed of two valve seats (2) which form the flow channel of the valve body after the buckle arrangement, and the valve body base (1) which is sleeved and connected on the outer surface of the proximal end of the two valve seats (2) (the two valve seats (2) The t...

Embodiment 2

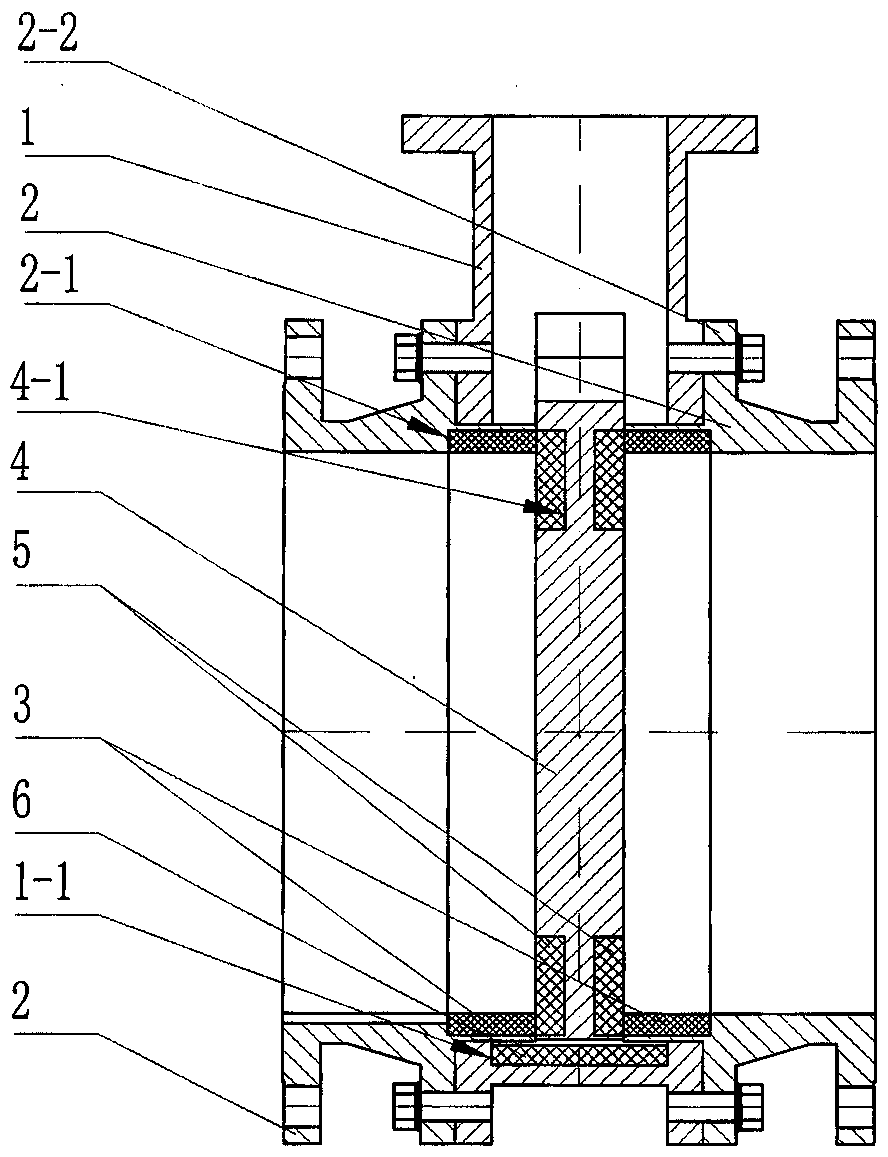

[0028] Such as figure 2 As shown, the difference between embodiment two and embodiment one is:

[0029] The gate ceramic (5) described in the second embodiment has a circular structure; the gate grooves (4-1) located on both surfaces of the gate base (4) are circular grooves; the gate grooves The shape and specification of (4-1) match the shape and specification of the gate ceramics (5).

[0030]In the second embodiment, the proximal ends of the two valve seats (2) are connected to the valve body substrate (1) through flanges and bolts; the outer surfaces of the proximal ends of the two valve seats (2) are all along the diameter A boss flange (2-2) protrudes outwards, and a bolt hole is processed on the boss flange (2-2), and is connected with the boss flange ( 2-2) Threaded holes are processed at the fitting parts.

[0031] Concrete usage of the present invention is as follows:

[0032] Firstly, the gate ceramics (5) are embedded and fixed in the gate grooves (4-1) on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com