Solid-phase adsorbing material, preparation method thereof and application of adsorbing material

A solid-phase adsorption and extraction agent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve strong adsorption capacity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Preparation and detection of solid-phase adsorption material (1)

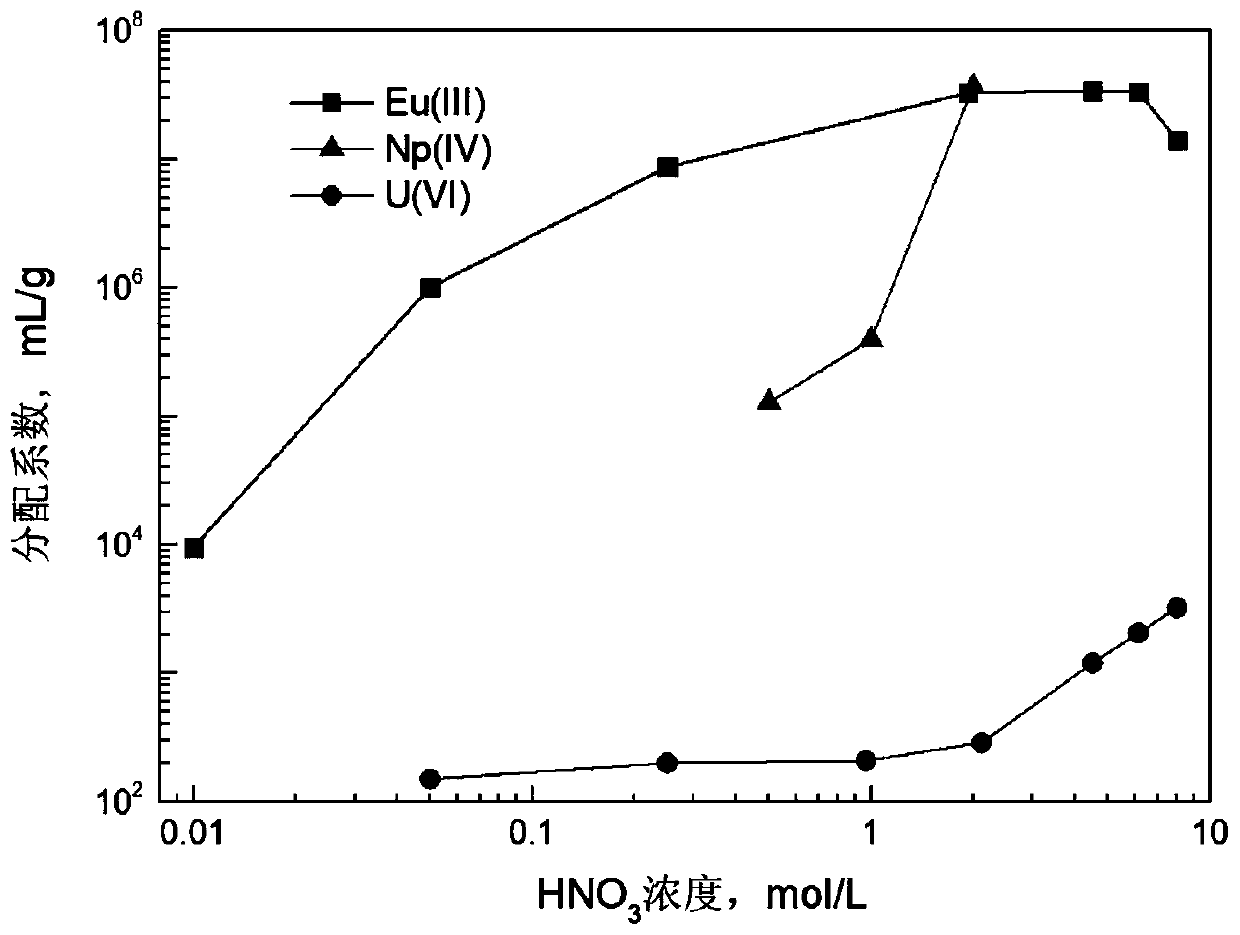

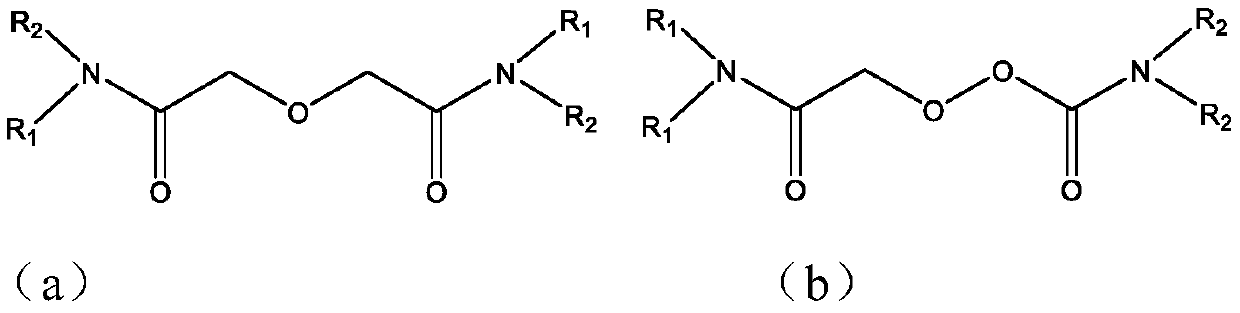

[0046] Using N,N'-dimethyl-N,N'-dioctyl-3-oxa-glutaramide as extractant and Amberlite XAD7HP as support to prepare solid-phase adsorption material, and its Partition coefficients for adsorption of metal ions from nitric acid solutions.

[0047] The preparation process is as follows:

[0048] (1) Dissolve 7.0 g of N,N'-dimethyl-N,N'-dioctyl-3-oxa-glutaramide (DMDODGA) in 40 mL of methanol;

[0049](2) Put Amberlite XAD7HP granules with a particle size of 20-60 mesh that have been dried to constant weight into a 250mL single-necked flat-bottomed flask, and put a polytetrafluoroethylene-coated magnet;

[0050] (3) Add the solution dropwise into the flask under electromagnetic stirring conditions, and stir for 30 minutes;

[0051] (4) Rotary evaporation at 40° C. to constant weight to obtain the target solid-phase adsorption material, wherein the mass content of DMDODGA is 35.0%.

[0052] Stat...

Embodiment 2

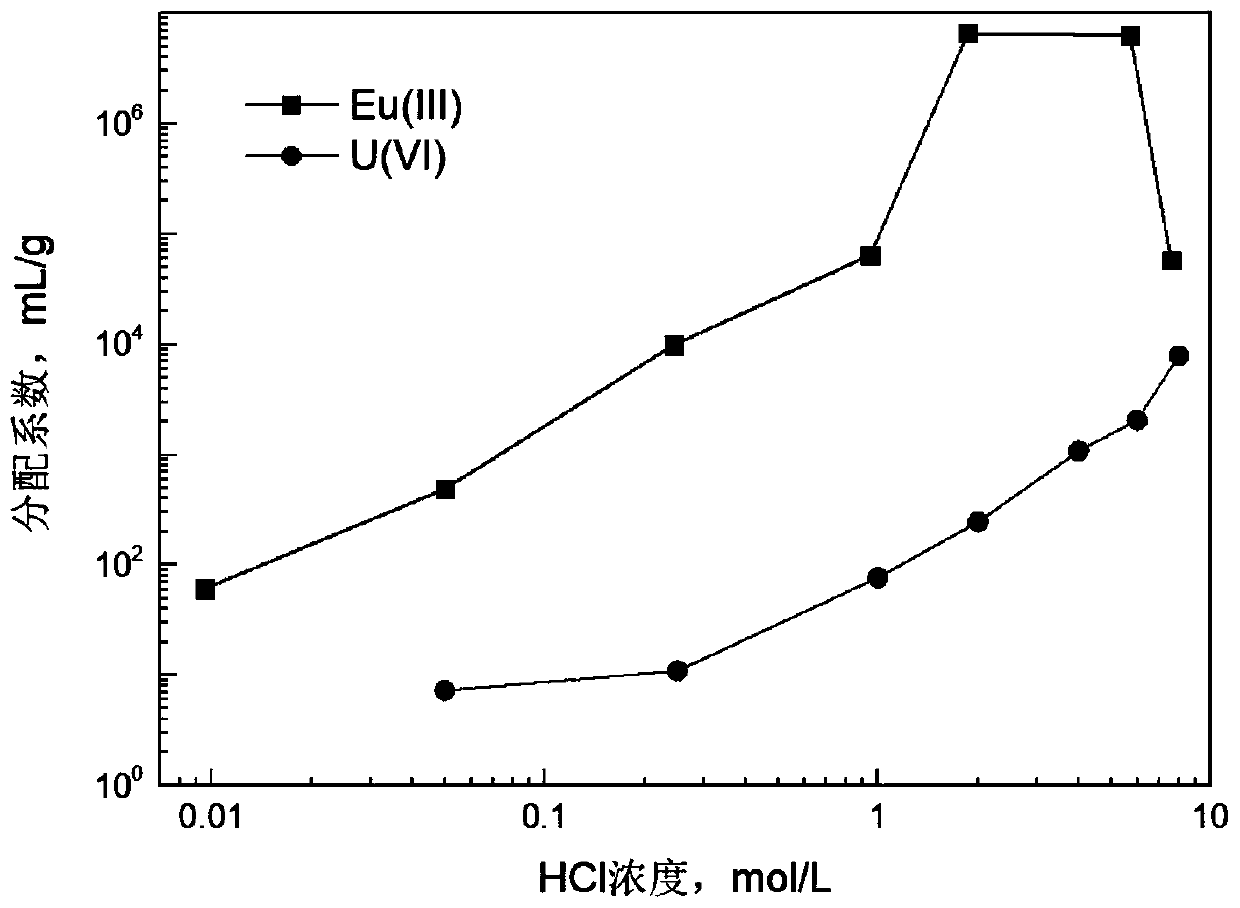

[0060] Embodiment 2: Preparation and detection of solid-phase adsorption material (two)

[0061] Preparation of solid phase with N,N'-dimethyl-N,N'-dioctyl-3-oxa-glutaramide as extractant and starting monomers with styrene and divinylbenzene as supports Adsorption material, and its distribution coefficient of adsorbing metal ions from hydrochloric acid solution was determined by static adsorption experiment.

[0062] The preparation process is as follows:

[0063] Mix 15.0g of styrene monomer and 10.0g of divinylbenzene monomer evenly, add 0.5g of purified azobisisopropionitrile (ALBN) as an initiator, and then add 15.0g of N,N'-dimethyl- N,N'-dioctyl-3-oxa-glutaramide (DMDODGA), stir well as the oil phase. In addition, 6.0g of gelatin was dissolved in 500mL of boiling water, then 0.5g of calcium carbonate and 0.05g of Triton X-100 were added and mixed uniformly as the water phase, and its temperature was kept at 45°C. Add the oil phase to the water phase, stir for 20 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com