A multi-layer plate frame floating photocatalytic water purification device and its application

A water purification device and photocatalysis technology, which is applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, reduced water/sewage treatment, etc., can solve the problems of low photocatalysis efficiency and low light utilization efficiency, and achieve the goal of ensuring light receiving area, reduce waste, and ensure stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

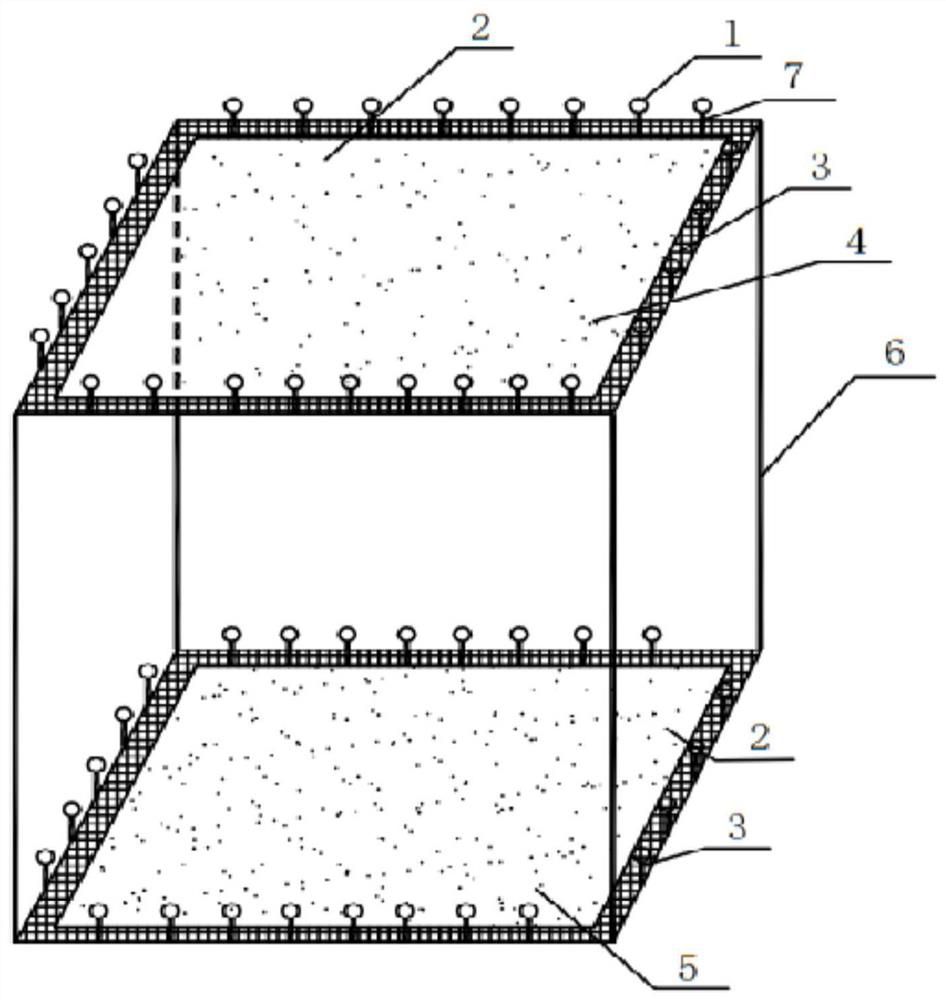

[0036] Such as figure 1 , 2 As shown, a multi-layer plate frame type floating photocatalytic water purification device includes a visible light catalytic unit and an ultraviolet photocatalytic unit, and the visible light catalytic unit and the ultraviolet photocatalytic unit are connected by connecting ribs 6; The catalytic unit includes a visible photocatalytic layer 4, and the ultraviolet photocatalytic unit includes a layer of ultraviolet photocatalytic layer 5;

[0037] The visible photocatalytic layer 4 includes a base fabric 2 and a plate frame 3, the base fabric 2 is loaded with a carbon nitride visible light catalytic material, and the base fabric 2 is fixedly arranged on the plate frame 3;

[0038] The ultraviolet photocatalytic layer 5 includes another base fabric 2 and another plate frame 3, the other base fabric 2 is loaded with titanium dioxide ultraviolet photocatalytic material, and the other base fabric 2 is fixedly arranged on the other plate frame 3;

[003...

Embodiment 2

[0043] As described in Example 1, the difference is:

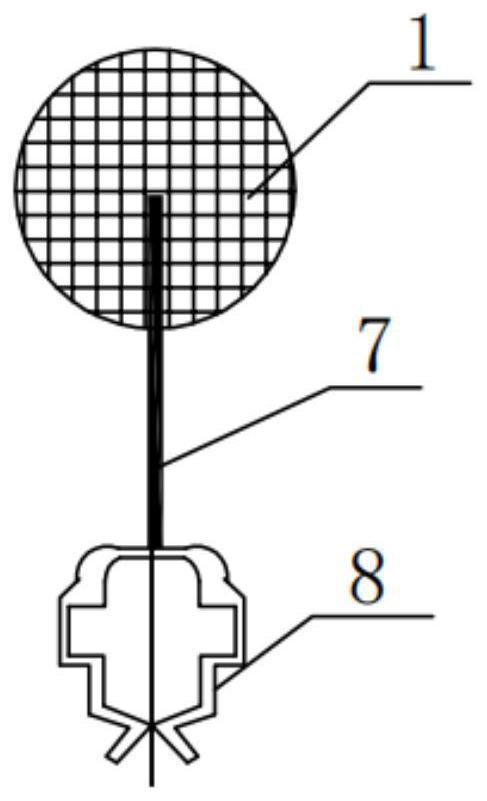

[0044] The plate frame 3 is only arranged around the base fabric 2 . This setting is beneficial to reduce the weight of the plate frame 3 itself, while protecting the base fabric 2 at the same time. The floating assist device 1 is a floating rod, which is fixedly connected to the plate frame 3 by binding the floating rod 7 with cable ties.

[0045] In this embodiment, the mesh gap between the base fabric 2 and the frame 3 in the visible photocatalytic layer 4 is 1 cm, and the mesh gap between the base fabric 2 and the frame 3 in the ultraviolet photocatalytic layer 5 is 0.4 cm. The distance between the visible photocatalytic layer 4 and the ultraviolet photocatalytic layer 5 is 20 cm.

Embodiment 3

[0047] As described in Example 1 or 2, the difference is:

[0048] A baffle is vertically arranged around the said plate frame 3, and the baffle is vertically arranged with the plate frame, and the height of the baffle is 1 cm.

[0049] In this embodiment, the mesh gap between the base fabric 2 and the frame 3 in the visible photocatalytic layer 4 is 1.5 cm, and the mesh gap between the base fabric 2 and the frame 3 in the ultraviolet photocatalytic layer 5 is 0.7 cm. The distance between the visible photocatalytic layer 4 and the ultraviolet photocatalytic layer 5 is 40 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com