A kind of preparation method of rubber composition filled with carbon nanotubes

A rubber composition, carbon nanotube technology, applied in transportation and packaging, rolling resistance optimization, special tires, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

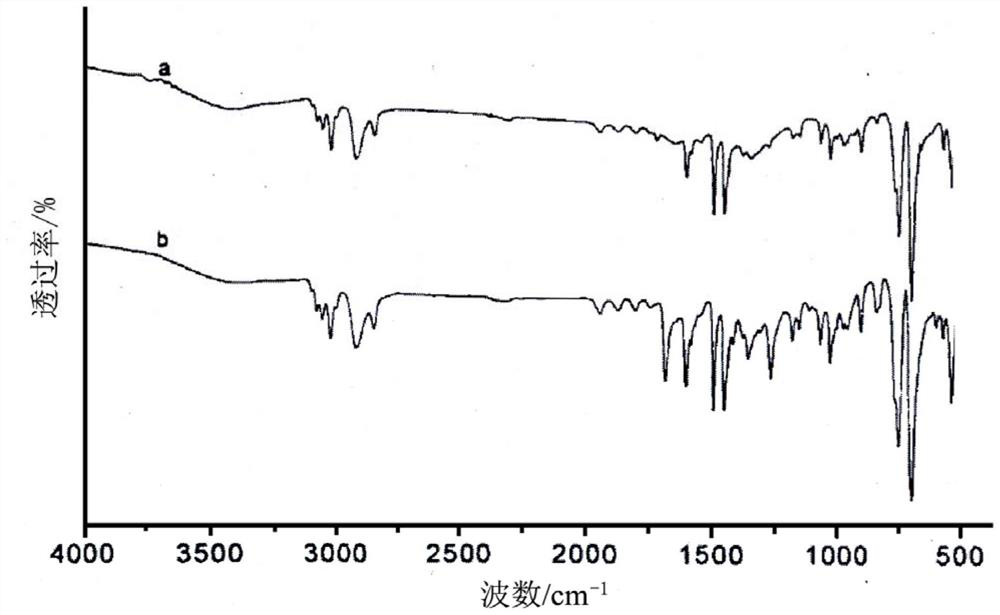

Image

Examples

Embodiment 1

[0037] (1) Preparation of highly dispersed carbon nanotubes:

[0038] a Preparation of carbon nanotubes by hydroxylation: 100 parts of carbon nanotubes, 150 parts of concentrated nitric acid, 10 parts of H 2 o 2 Put them together into the reactor and mix them, use 50kHz ultrasonic treatment for 1.0hr, then heat to 50°C, stir and cook with acid for 1hr, cool, filter with suction, wash until the filtrate is neutral, finally add 200 parts of ethylene glycol, and then heat to Stirring and reacting at 50° C. for 1 hr, suction filtration, washing, and drying to obtain carbon nanotube a with hydroxyl groups on the surface.

[0039] b Preparation of acylated styrene-butadiene latex: first add 100 parts of styrene-butadiene latex SBR1500, 1 part of sodium dodecylbenzenesulfonate emulsifier, 5 parts of CS 2 , stirring and heating, when the temperature of the polymerization tank reaches 25°C, quickly add 0.01 part of anhydrous aluminum trichloride under stirring conditions, until the s...

Embodiment 2

[0043] (1) Preparation of highly dispersed carbon nanotubes:

[0044] a Preparation of carbon nanotubes by hydroxylation: same as in Example 1.

[0045] The preparation of b acylated styrene-butadiene latex: with embodiment 1.

[0046] c Preparation of highly dispersed carbon nanotubes: Take 100 parts of carbon nanotubes a, 1.0 parts of ethylene glycol laurate, 350 parts of deionized water, and 2.0 parts of sodium hydroxide and add them to the polymerization tank and stir and mix for 20 minutes; then add 2.0 parts 1 part of sodium dodecylbenzenesulfonate, 3.0 parts of acylated styrene-butadiene latex a, stirred and heated to 60°C, stirred and reacted for 3 hours, washed, dehydrated, dried, and ground to obtain highly dispersed carbon nanotubes.

[0047] (2) Preparation of styrene-butadiene rubber composition for tread: take 100 parts of styrene-butadiene latex SBR1500 (dry rubber), 1.5 parts of sodium dodecylbenzene sulfonate, and 250 parts of deionized water and add them to ...

Embodiment 3

[0049] (1) Preparation of highly dispersed carbon nanotubes:

[0050] a Preparation of carbon nanotubes by hydroxylation: 100 parts of carbon nanotubes, 180 parts of concentrated nitric acid, 25 parts of H 2 o 2 Put them into the reactor and mix them together, treat with 60kHz ultrasonic wave for 1.5hr, then heat to 100°C, stir and cook with acid for 5hr, cool, filter with suction, wash until the filtrate is neutral, finally add 400 parts of ethylene glycol, and then heat to Stirring and reacting at 70° C. for 3 hours, suction filtration, washing and drying to obtain carbon nanotube b with hydroxyl groups on the surface.

[0051] b Preparation of acylated styrene-butadiene latex: first add 100 parts of styrene-butadiene latex SBR1500, 3 parts of sodium dodecylbenzenesulfonate emulsifier, 8 parts of CS 2 , stirring and heating, when the temperature of the polymerization tank reaches 35°C, quickly add 0.11 parts of anhydrous aluminum trichloride under stirring conditions, unti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com