Method for improving phosphorus efficient enriching effect in phosphorus-contained steel slag

A technology of enrichment and steel slag, which is applied to the improvement of process efficiency, fertilizer mixture, manufacturing converters, etc., can solve the problems of phosphorus content that requires steel slag waste heat to be unusable and low phosphorus content, so as to promote efficient migration, increase content, and content increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

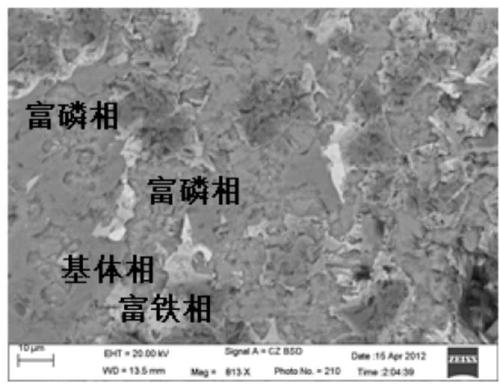

[0026]This method is used to treat high-basic phosphorus-containing slag after dephosphorization of a converter in a factory. The specific implementation process is as follows: (1) After the converter smelting and tapping is completed, a certain amount of SiO is added to the bottom of the special slag tank in advance during the high temperature steel slag tapping process. 2 Modifier, SiO 2 10% of the amount of slag produced by the modifier, and the basicity of the modified slag (CaO / SiO 2 ) is 1.5 to 2.0. The components of the original converter slag and modified slag after smelting in this plant are shown in Table 1; (2) After the high-temperature steel slag is poured into the special slag tank, the The steel slag temperature was controlled at 1500°C and kept for 30 minutes to ensure that the slag and the modifier fully melted and reacted; (3) Then the slag was cooled at a temperature drop rate of 5°C / min, and when the slag temperature dropped to 1360°C, the slag was Keep w...

Embodiment 2

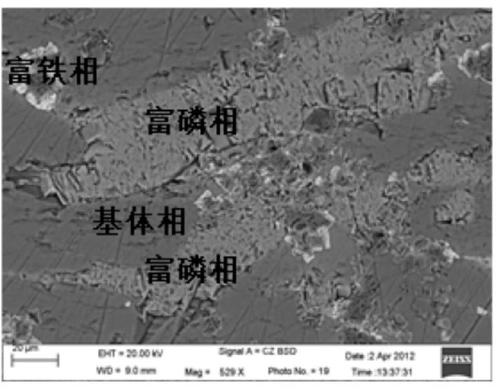

[0033] This method is used to treat high-basic phosphorus-containing slag after dephosphorization of a converter in a factory. The specific implementation process is as follows: (1) After the converter smelting and tapping is completed, a certain amount of Al is added to the bottom of the special slag tank in advance during the high temperature steel slag tapping process. 2 o 3 Modifier, Al 2 o 3 15% of the amount of slag produced by the modifier. The composition of the original converter slag after smelting in this plant is shown in Table 3; (2) After the high-temperature steel slag is poured into the special slag tank, the The steel slag temperature is controlled at 1480°C and held for 30 minutes to ensure that the slag and the modifier are fully melted and reacted; (3) Then the slag is cooled at a temperature drop rate of 5°C / min, and when the slag temperature drops to 1350°C, the slag is kept warm 60min to fully promote 3CaO·P 2 o 5 The precipitation of phosphorus in ...

Embodiment 3

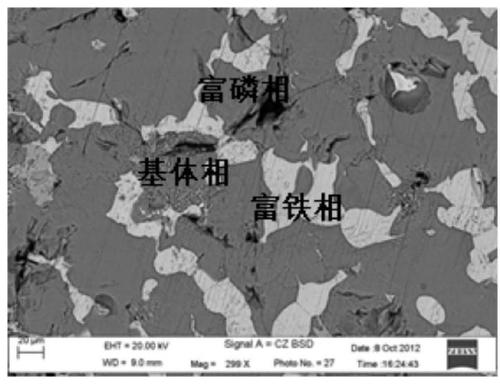

[0040] For other steel slags such as phosphorus-containing electric furnace slag and phosphorus-containing molten iron pretreatment slag produced in the iron and steel smelting process, the process method for highly efficient enrichment of phosphorus in phosphorus-containing slag in this embodiment is also applicable. Due to the different parameters such as slag type, slag composition, and phase properties, the control conditions such as the type of modifier, the amount of modifier added, the control temperature, the cooling rate, and the holding time are also different when using the slag treatment process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com