Noise reduction type drilling and tapping all-in-one machine

An all-in-one, noise-reducing technology, applied in metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc. The effect of waste chip splashing, easy adjustment of workpiece and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

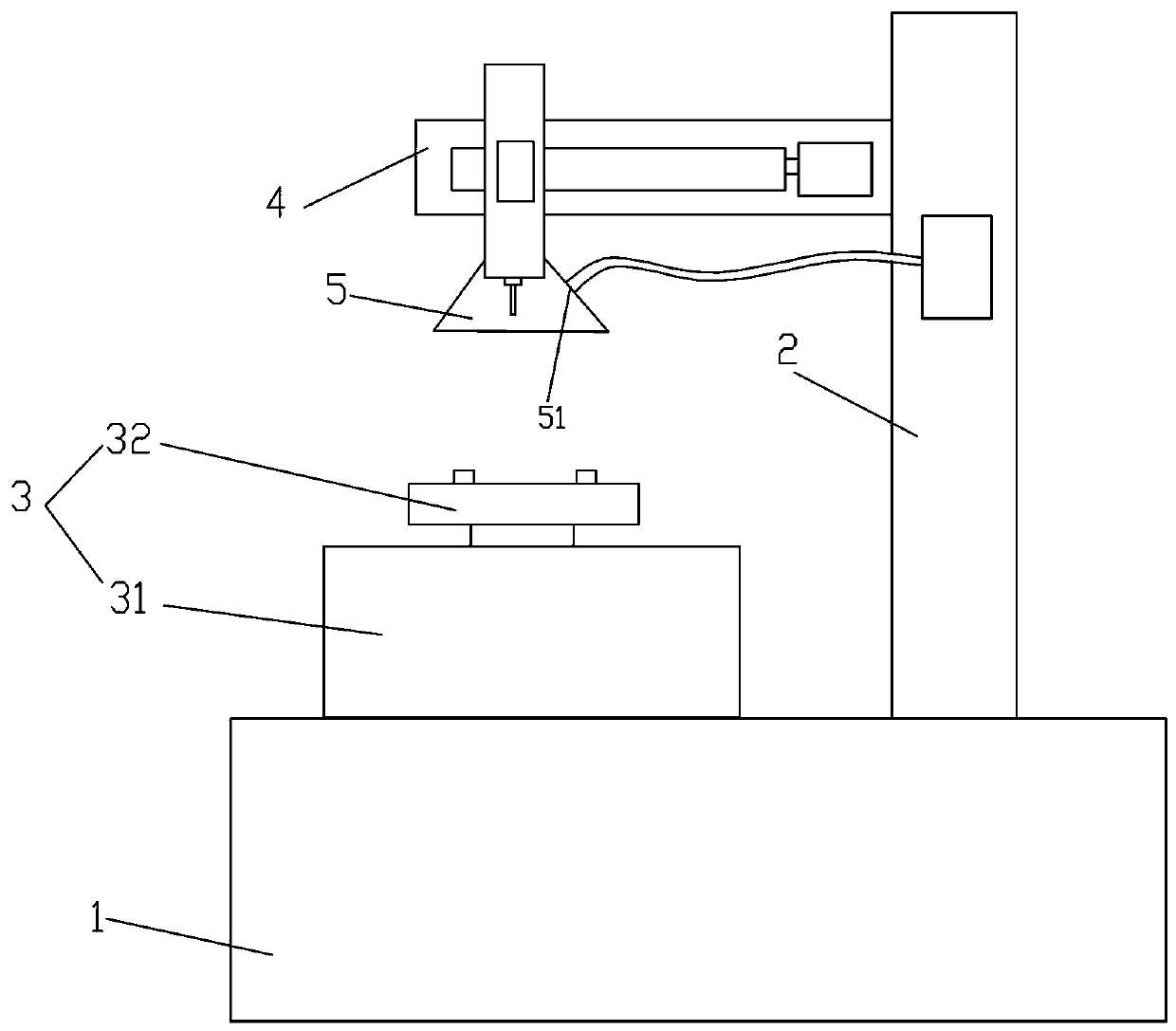

[0026] Such as figure 1 As shown, this embodiment provides a noise-reducing integrated drilling and tapping machine, including a base 1, a column 2, a workbench 3, drilling parts and tapping parts, and also includes a The crossbeam 4 connected to the upper end, the drilling part and the tapping part are connected to the crossbeam 4 and can move back and forth along the length direction of the crossbeam 4, and the crossbeam 4 is provided for driving the drilling part and The tapping part is a translation assembly that reciprocates along the length direction of the crossbeam 4, and the column 2 is provided with a lifting assembly for driving the crossbeam 4 to lift vertically. When the crossbeam 4 descends, the drilling part and the tapping part will also As the crossbeam 4 descends synchronously, it rises in the same way; the workbench 3 includes a sound-absorbing chip storage box 31 with an opening formed on the top of the base 1 and a sound-absorbing chip storage box 31 above...

Embodiment 2

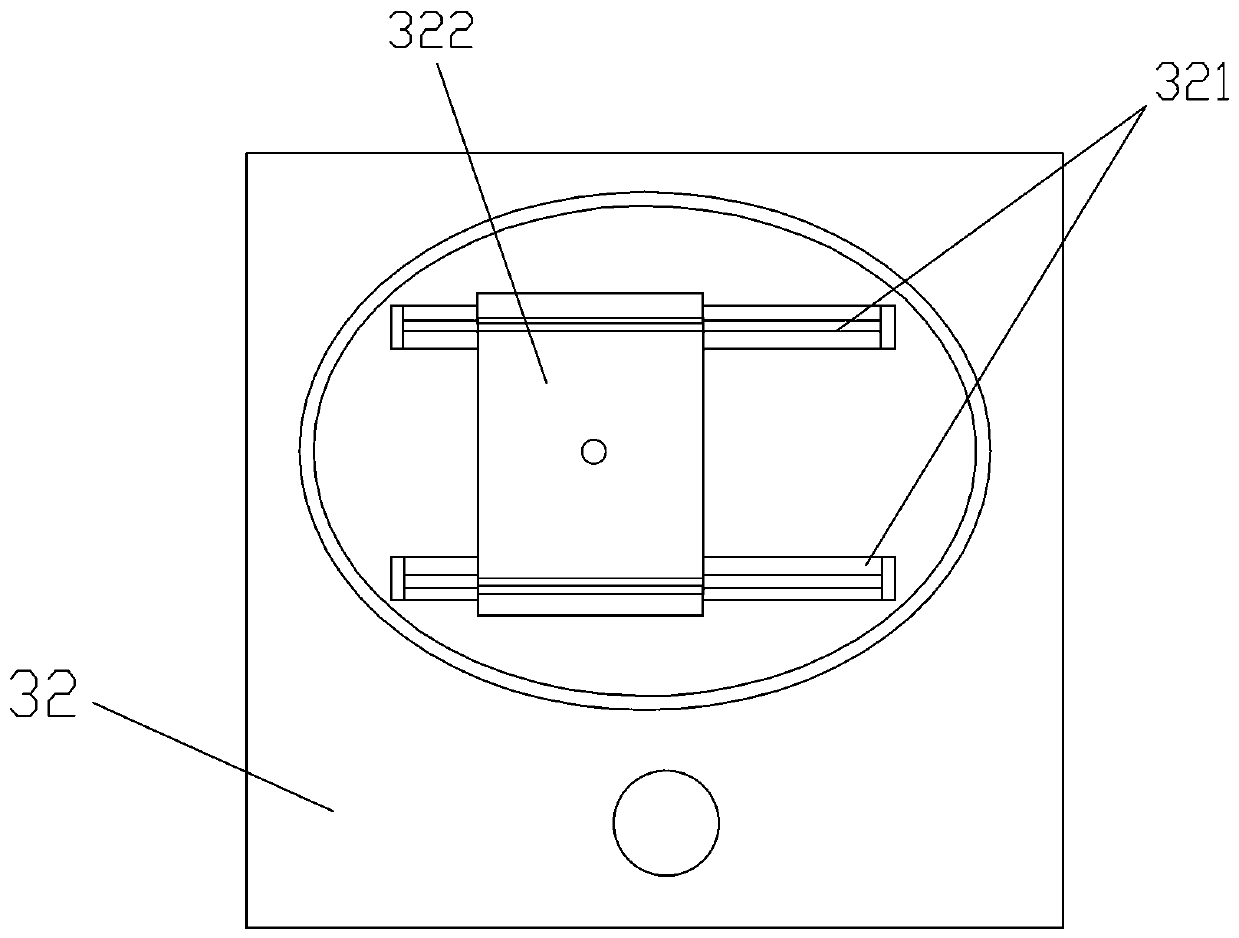

[0031] In order to better create a vacuum space in the protective cover 5 and reduce noise better in this embodiment, the upper surface of the sound-absorbing debris storage box 31 is provided with a ring for connecting with the lower end of the protective cover 5 around the periphery of the fixed table 32. Sealing rings for airtight connections. It is beneficial to better seal the space surrounded by the upper surface of the protective cover 5 and the sound-absorbing chip storage box 31. When the blowing device sucks air, the vacuum of the space should be guaranteed as far as possible, so as to isolate the transmission of sound, thereby reducing noise.

[0032] Optionally, a sealing groove is formed on the upper surface of the sound-absorbing chip storage box 31 around the periphery of the fixed table 32, and liquid is contained in the sealing groove. The sealing groove and the liquid form a water-sealed structure, which is conducive to ensuring the vacuum environment of the ...

Embodiment 3

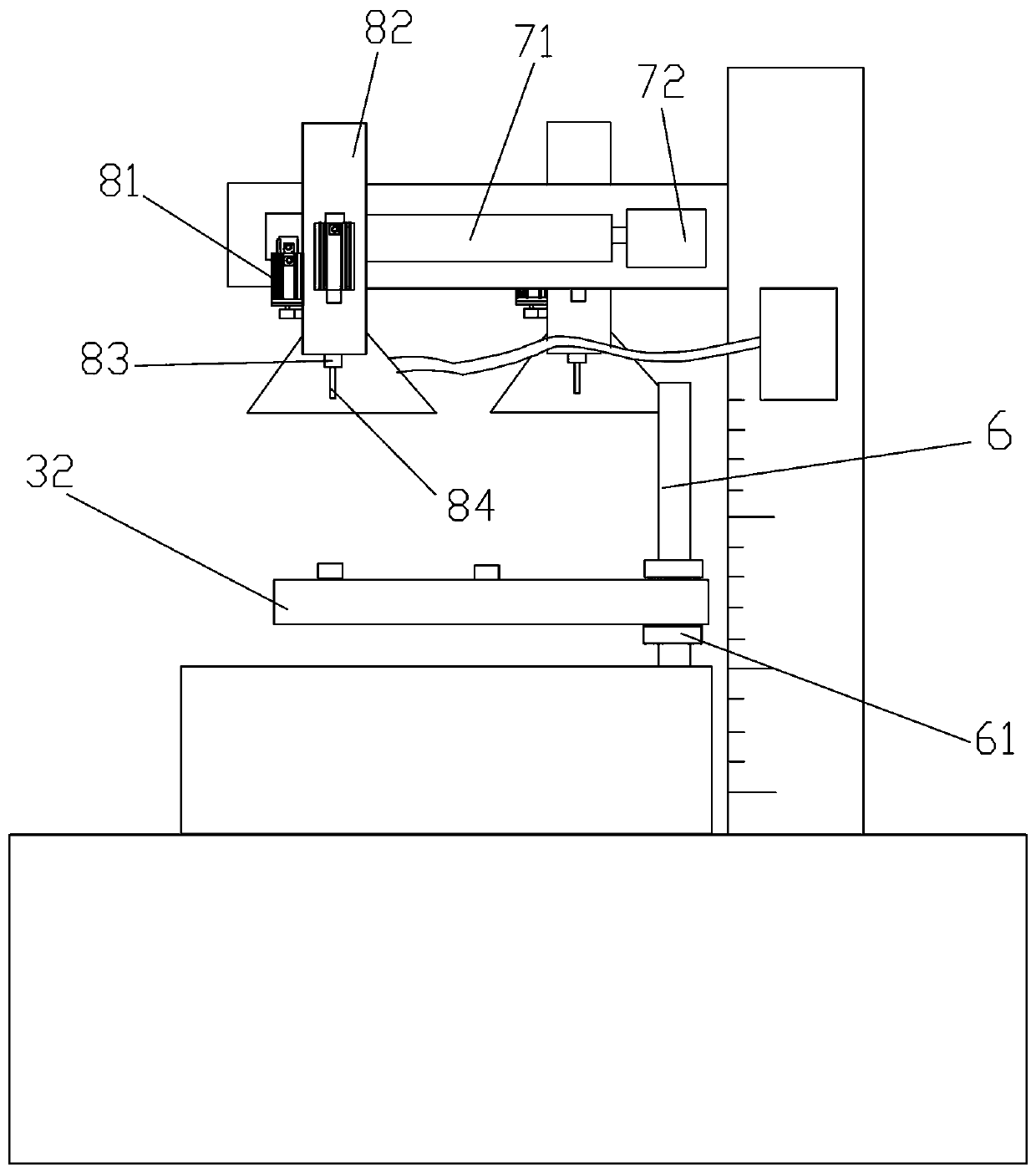

[0035] Such as figure 2 As shown, the difference between this implementation and the previous embodiments is that in this embodiment, in order to improve the versatility and work efficiency of the equipment, the base 1 is vertically provided with a threaded rod 6 close to the column 2, and the threaded rod 6 There are at least two nuts 61 connected thereto, and a through hole is opened on one side of the fixing platform 32 , and the fixing platform 32 is fixed to the threaded rod 6 through the through holes and the nuts 61 . Specifically, the fixed table 32 is socketed on the threaded rod 6 through the through hole, and the two nuts 61 are respectively located above and below the through hole to limit the fixed table 32 and prevent its height from changing and rotating. When it is necessary to adjust the fixed table 32 height, only need to turn the nut 61 to change the position of the fixed table 32 on the threaded rod 6 and then tighten the nut 61; in summary, it is benefici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com