Device and method capable of precisely controlling and transmitting nanowire

A nanowire and precision technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of nanowire bending deformation, not suitable for nanowire, rough control of nanowire, etc., and achieve the effect of quick control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

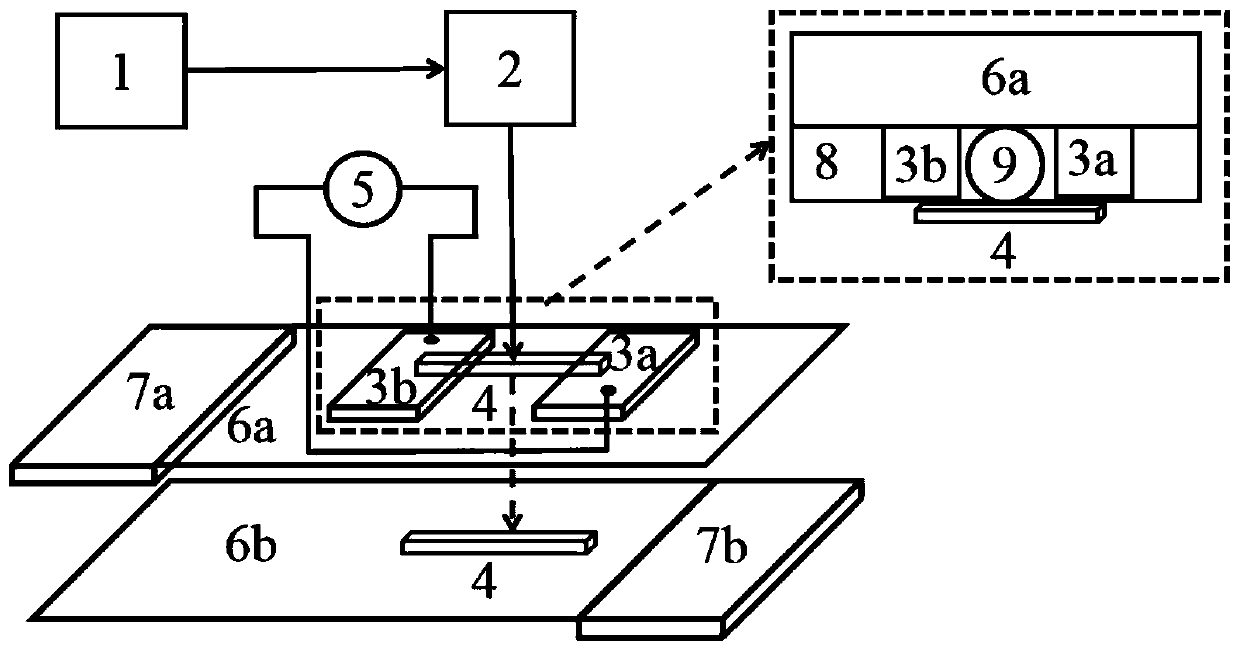

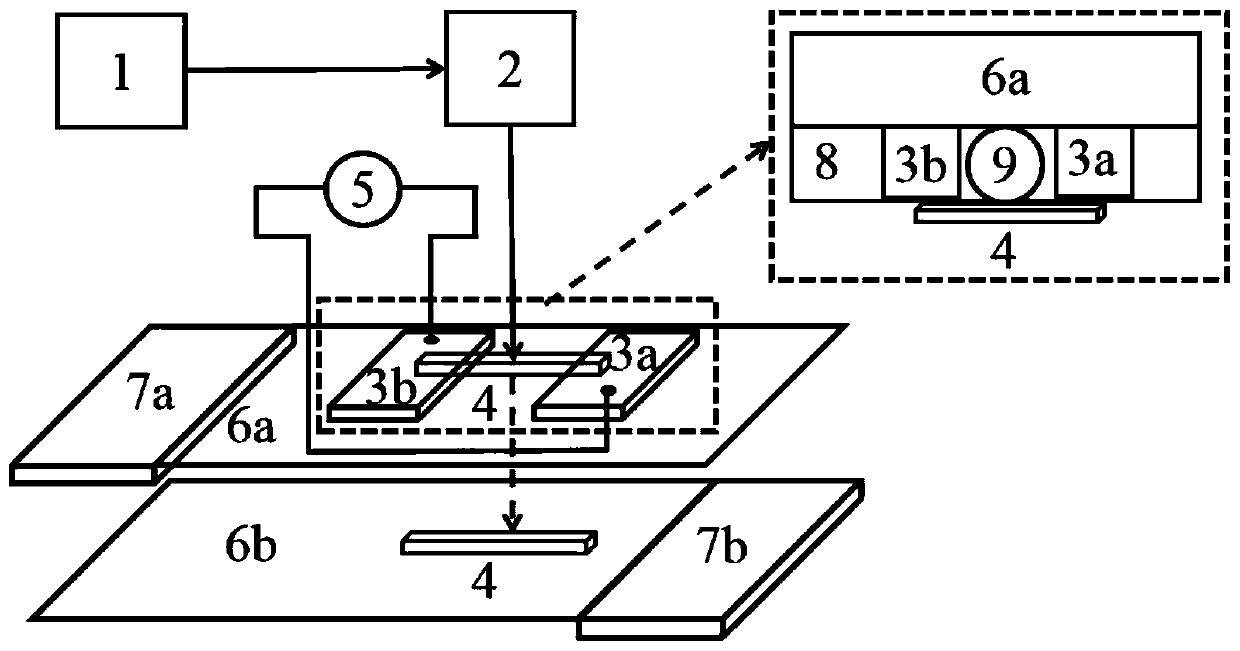

[0038] figure 1 It is a schematic structural diagram of a device for precisely manipulating and delivering nanowires according to an embodiment of the present invention, such as figure 1 As shown, the device combines dielectrophoresis technology and laser-induced forward transfer technology based on graphene oxide as a dynamic release layer to precisely manipulate and deliver nanowires. The device includes:

[0039] The femtosecond pulse light source 1 is used to generate femtosecond pulse laser with high power and relatively narrow pulse width. In this embodiment, a commercial titanium sapphire laser of the type LibraS from Coherent Company of the United States is selected. The shortest pulse width of the laser output is about 100fs, the average power is 1W, the repetition frequency is 1kHz, and the center wavelength is 800nm.

[0040] The microscope objective lens 2 is used for focusing the femtosecond pulsed laser light emitted by the femtosecond pulsed light source 1 . ...

Embodiment 2

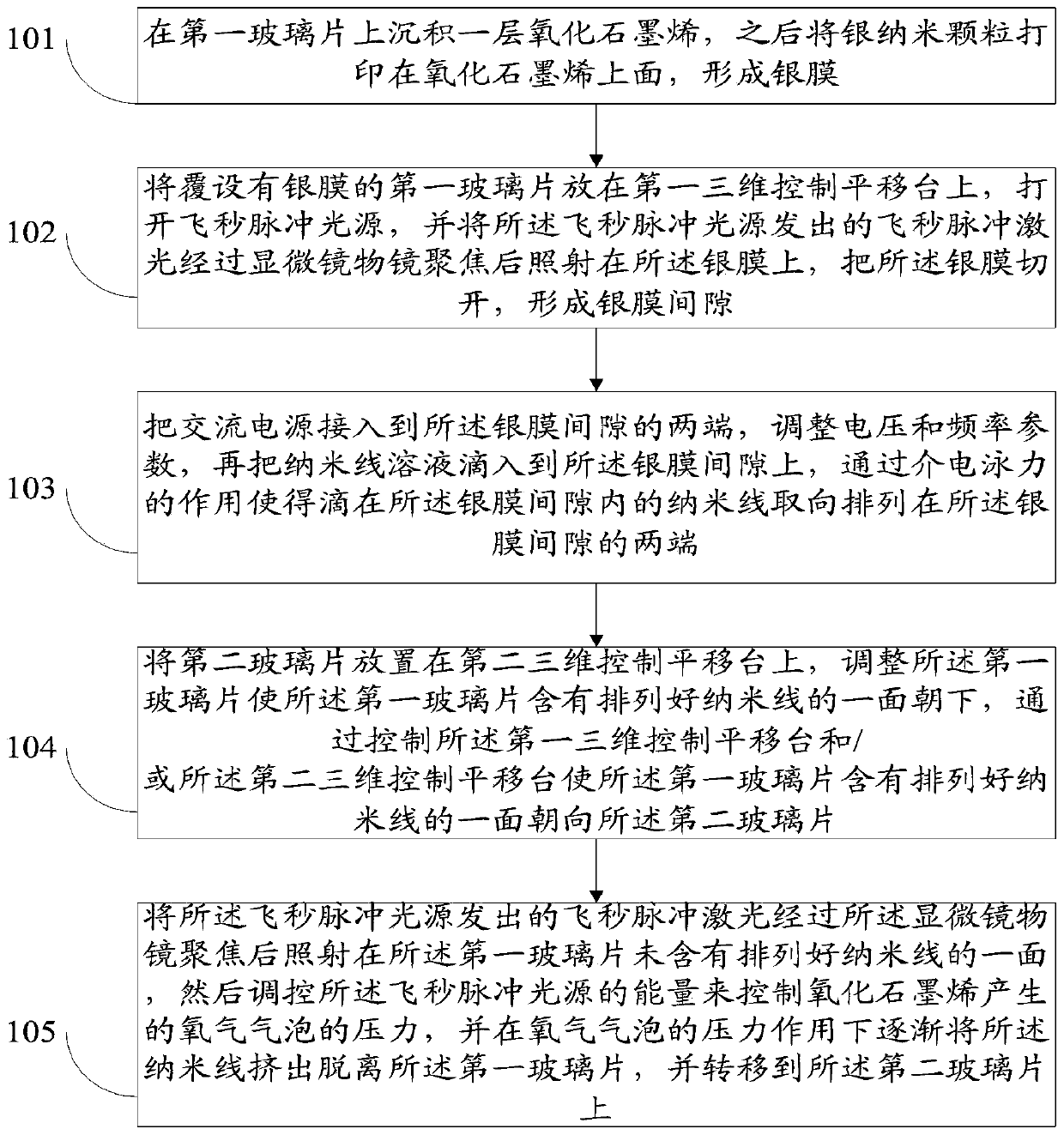

[0050] figure 2 It is a schematic flow diagram of a method for precise manipulation and delivery of nanometers according to an embodiment of the present invention, such as figure 2 As shown, a method for precisely manipulating and delivering nanowires provided in this embodiment includes:

[0051] Step 101: Deposit a layer of graphene oxide on the first glass sheet, and then print silver nanoparticles on the graphene oxide to form a silver film.

[0052] Step 102: Put the first glass sheet covered with silver film on the first three-dimensional control translation stage, turn on the femtosecond pulse light source, and irradiate the femtosecond pulse laser emitted by the femtosecond pulse light source through the microscope objective lens On the silver film, the silver film is cut to form silver film gaps.

[0053] Step 103: Connect the AC power supply to both ends of the silver film gap, adjust the voltage and frequency parameters, and then drop the nanowire solution into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com