Nanometer material as well as preparation method and application thereof

A nanomaterial and carbon nanotube technology, applied in the field of materials, can solve the problems of low biodegradability and poor removal effect, and achieve the effects of simple operation, cost saving and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Nanomaterials

[0033] (1) Accurately weigh 20 mg of carbon nanotube powder with an analytical balance, add it into a 250 mL Erlenmeyer flask filled with pure water, and prepare a 0.08 g / L carbon nanotube solution.

[0034] (2) Using an analytical balance, accurately measure 15 mg of laccase and add it to the above-mentioned Erlenmeyer flask, that is, mix the laccase and carbon nanotubes according to the mass ratio of laccase:carbon nanotubes=3:4 to obtain a mixed solution.

[0035] (3) Put the above mixed solution into an oscillator with a temperature of 10° C. and a rotation speed of 250 rpm for 30 minutes to vibrate for 30 minutes to immobilize the laccase on the carbon nanotubes to obtain nanomaterials.

[0036] Such as figure 1 As shown, in this example, laccase was successfully immobilized on carbon nanotubes.

Embodiment 2

[0038] In this example, the nanomaterials prepared in Example 1 were fitted to the Langmuir model and the Freundlich model respectively.

[0039] After the fitting of the Langmuir model and the fitting of the Freundlich model are carried out to the nanomaterial provided in Example 1, it is found that the fitting of the Langmuir model of the nanomaterial is better than the fitting of the Freundlich model, and the correlation coefficient R 2 It is 0.9973, reaching more than 0.99, indicating that the process of carbon nanotube adsorption of laccase in this nanomaterial is reversible adsorption, and it is unimolecular adsorption, indicating that the adsorption is physical adsorption.

Embodiment 3

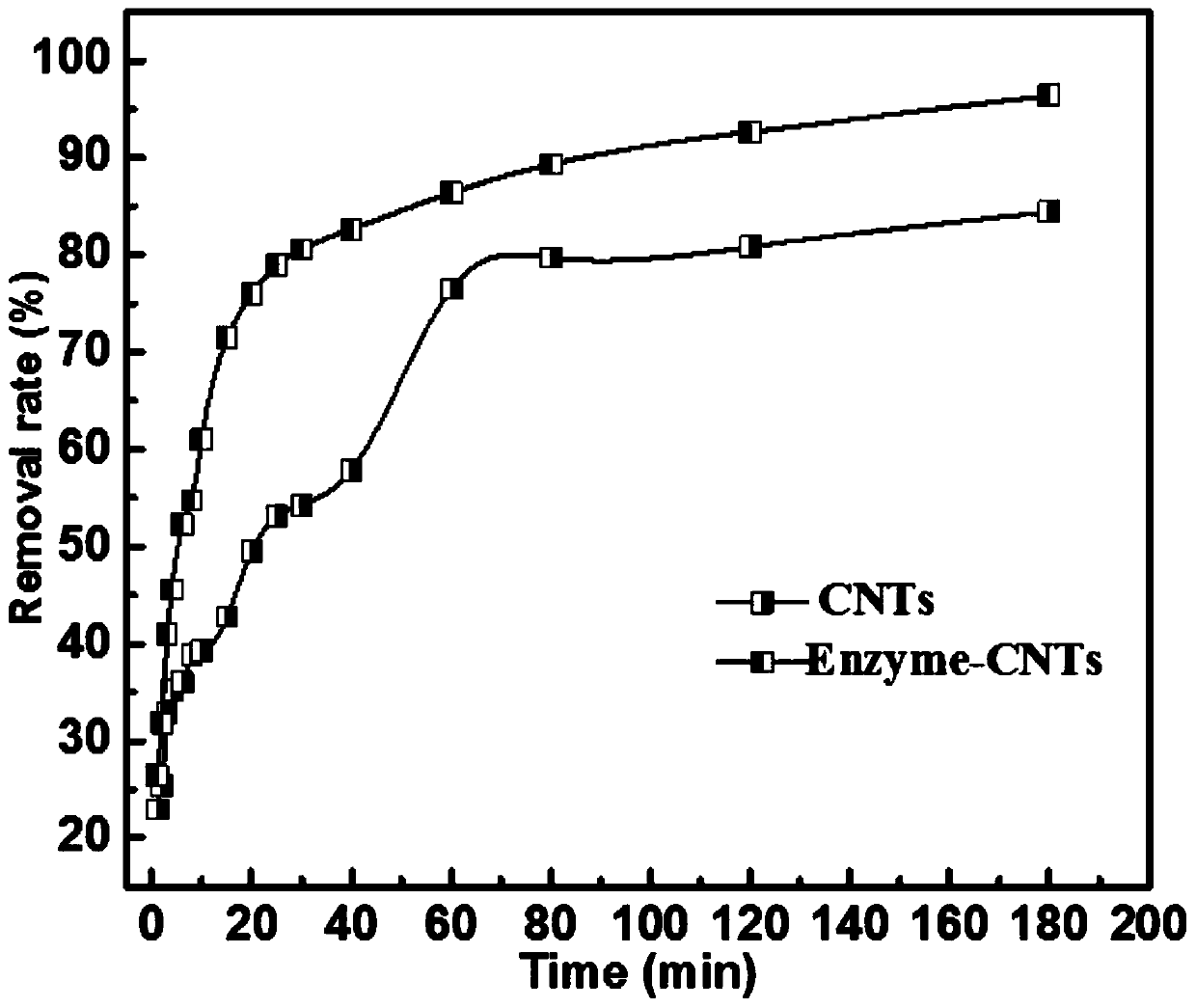

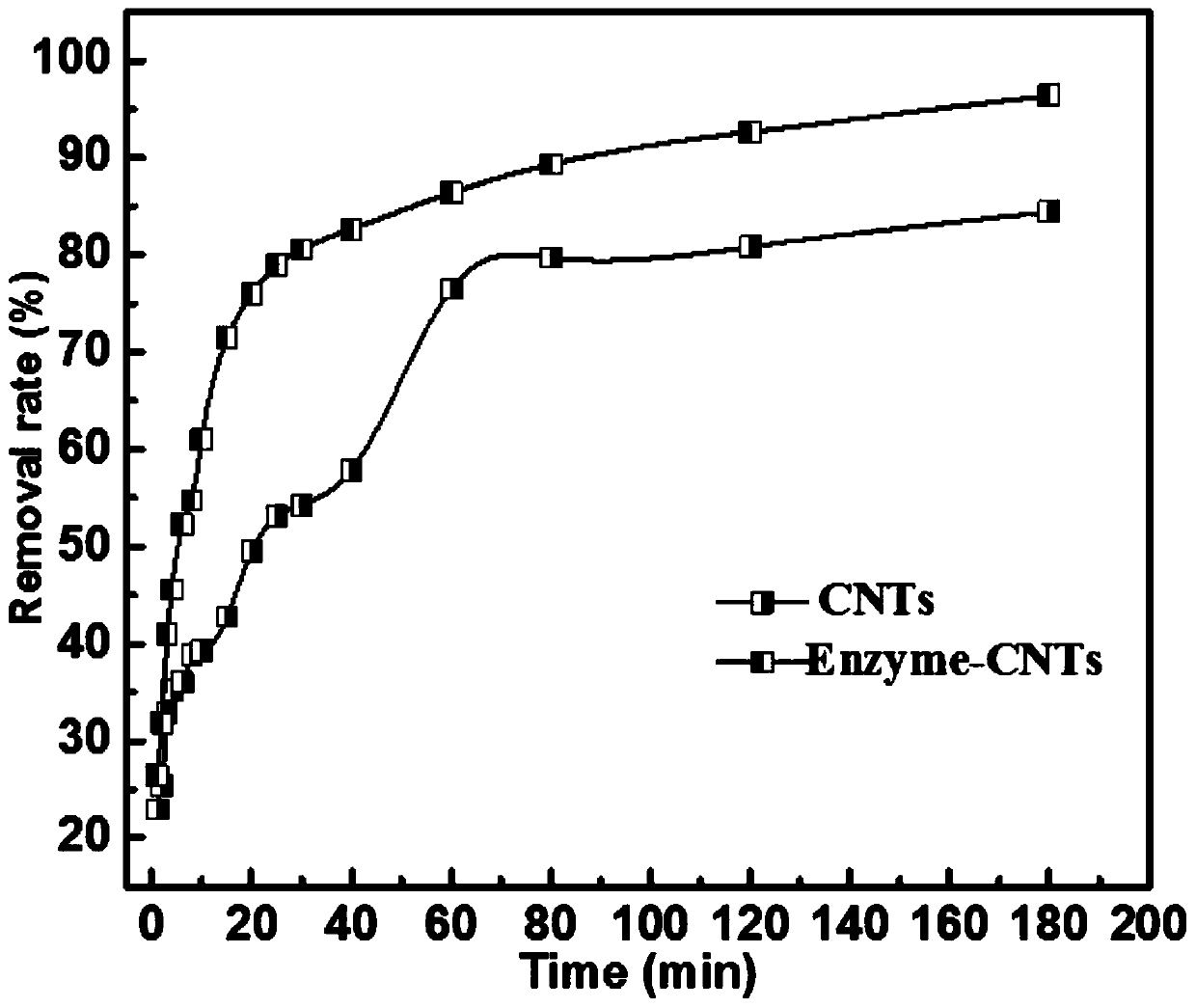

[0041] In this example, the carbon nanotubes without laccase immobilization were used as the control group, and the nanomaterials prepared in Example 1 were used as the experimental group to conduct sewage treatment tests.

[0042] (1) Add the nanomaterial provided in Example 1 (100mL concentration is 0.08g / L) to 100mL Congo red standard solution with an initial concentration of 40mg / L, at a temperature of 25°C and an oscillator speed of 150rpm, carry out for 30min Adsorption experiment.

[0043] (5) At 0, 20, 40, 60, 80, 10, 120, 140, 160, 180, and 200 minutes of adsorption, pipette the nanomaterial with a syringe and filter it with a filter, then detect it with a UV-Vis spectrophotometer, Measure the concentration of the remaining dye in the solution, calculate the removal rate according to the standard curve, and draw the relationship between the removal rate and the reaction time.

[0044] Such as figure 2 As shown, the nanomaterial provided by Example 1 of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com