Preparation and purification method of different domain oligosaccharides of heparan sulfate/heparin

A technology of heparan sulfate and heparin oligosaccharides, which is applied in the direction of fermentation and can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take the preparation of five crude samples of HS / Hp oligosaccharides containing different domain structures (disaccharide, tetrasaccharide, hexasaccharide, octasaccharide and decasaccharide) as an example:

[0037] 1. Preparation of Heparan Sulfate / Heparin (HS / Hp) Oligosaccharides

[0038]Weigh 200 mg commercially available heparin and dissolve it in 10 mL Tris-HCl buffer (containing 20 mmol / L Tris and 5 mmol / L calcium chloride, adjust the pH to 7.40 with HCl), add 20mIU heparinase I, and heat the enzyme in an oven at 40°C After 24 hours of solution, the reaction was terminated by inactivation at 100°C for 5 minutes, centrifuged at 12,000 r / min for 10 minutes, and the supernatant was collected and freeze-dried at -80°C for 5 hours.

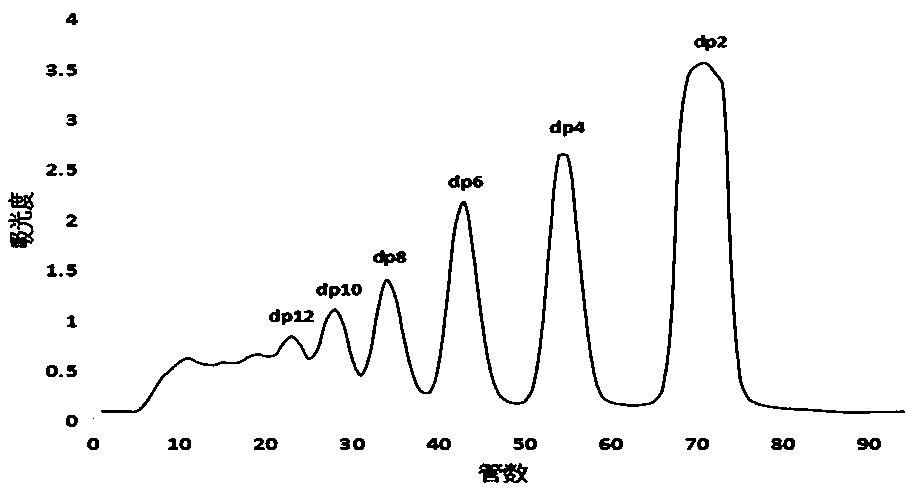

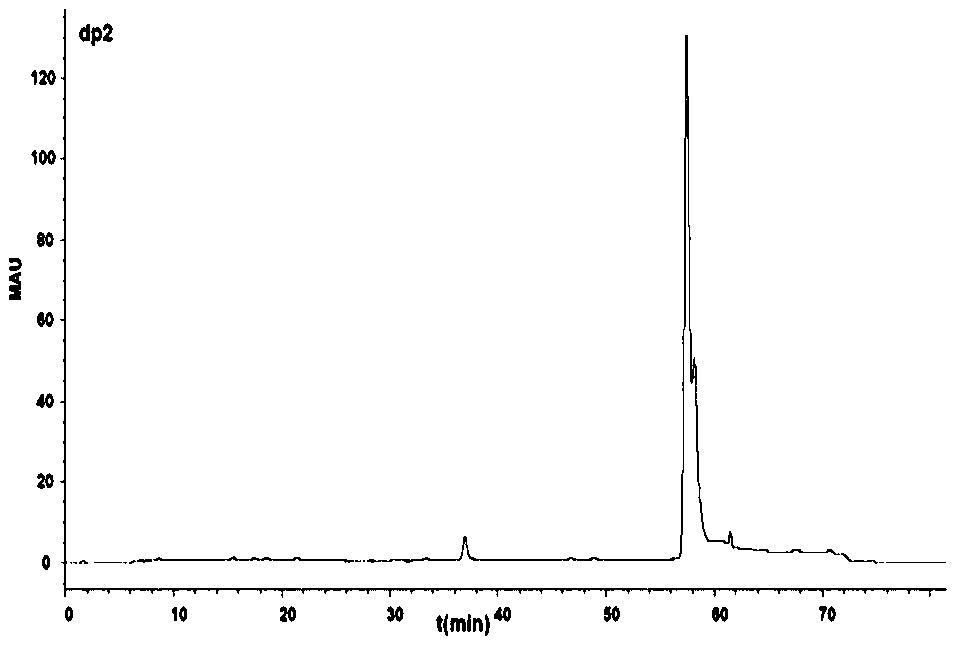

[0039] Separation and collection of disaccharides, tetrasaccharides, hexasaccharides, octasaccharides and decasaccharides

[0040] Take 140mg of the above freeze-dried sample, and use 3mL 0.2M NH 4 HCO 3 Dissolved and separated by polyac...

Embodiment 2

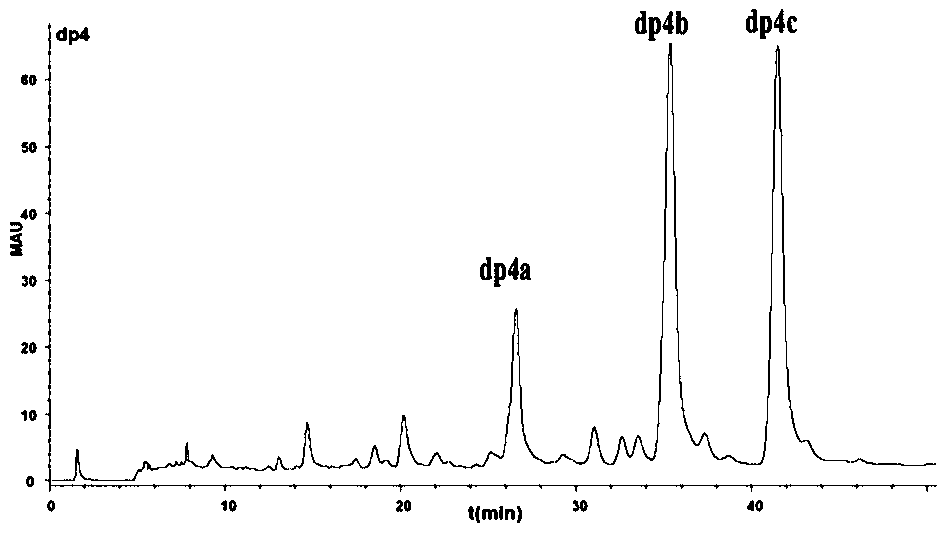

[0049] Take the preparation of fifteen low-sulfated HS / Hp oligosaccharide pure products as an example:

[0050] 1. Enzymatic hydrolysis of heparan sulfate / heparin (HS / Hp)

[0051] Weigh 100 mg of commercially available heparin and dissolve it in 5 mL of Tris-HCl buffer (containing 20 mmol / L Tris and 5 mmol / L calcium chloride, adjust the pH to 7.40 with HCl), add 10 mIU of heparinase I and perform enzymatic hydrolysis in an oven at 40 °C After 24 h, the reaction was terminated by inactivation at 100 °C for 5 min, centrifuged at 12000 r / min for 10 min, and the supernatant was collected and freeze-dried.

[0052] Preparation of oligosaccharides

[0053] Take 140mg of the above freeze-dried sample, and use 3mL 0.2M NH 4 HCO 3 Dissolved, separated by polyacrylamide gel chromatography column (Bio-GelP-10), and collected the corresponding chromatographic peaks of each heparin oligosaccharide. Volatilize NH in an oven at 55 °C for 72 h 4 HCO 3 After vacuum freeze-drying at -80°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com