Scattered paving method mechanized construction equipment for urban railway and construction method thereof

A technology for construction equipment and urban rails, applied in the directions of rails, laying rails, rail maintenance, etc., can solve the problems of difficult material transfer, low construction efficiency, and high labor costs, so as to enhance the level and ability of construction technology, reduce construction costs, and improve The effect of the technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

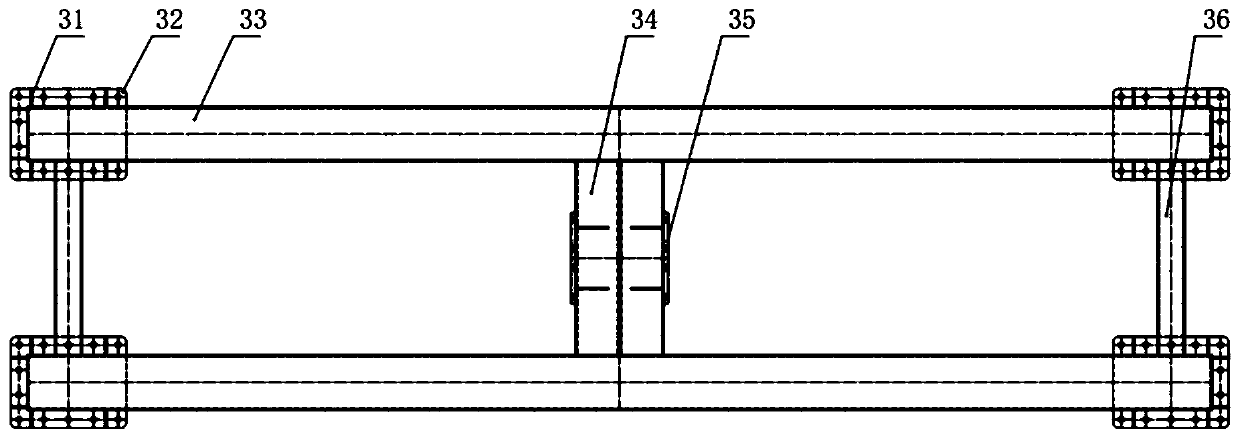

[0055] The design of the present invention is mainly composed of three major systems, namely: rail row hoisting door machine device, inverted door machine system, prefabricated flat car system, etc., such as Figure 21 shown.

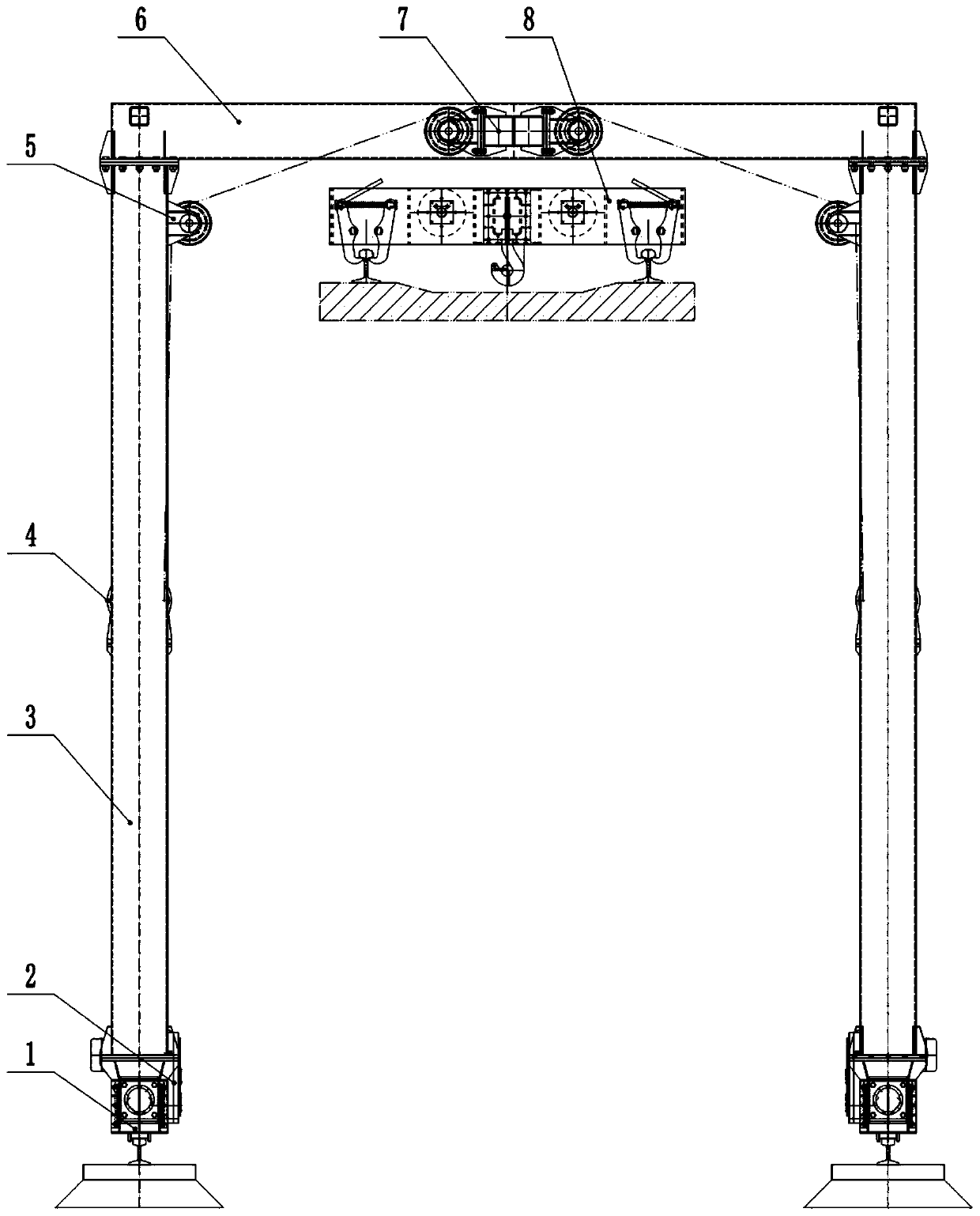

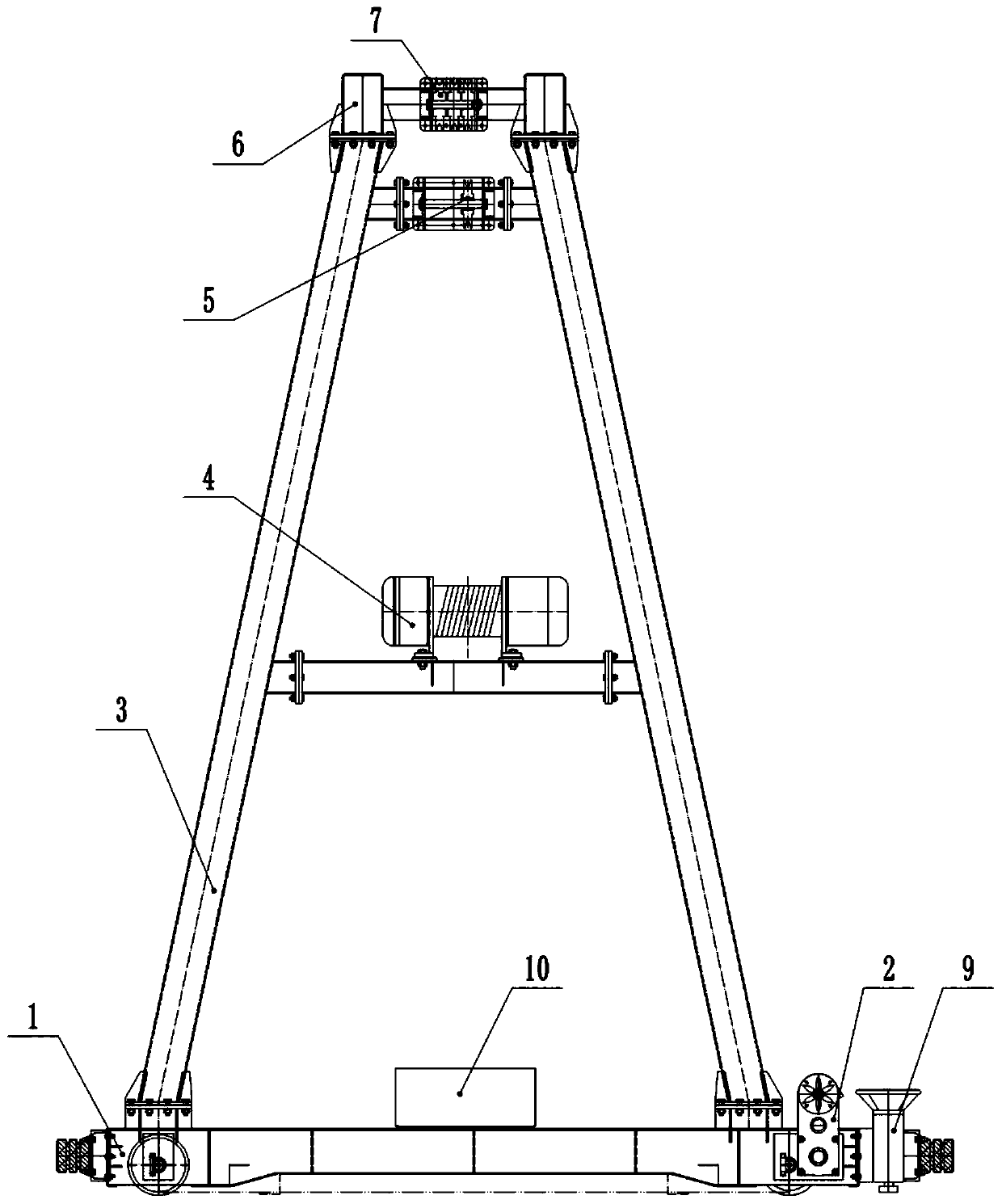

[0056] Among them, the structural diagram of the rail row hoisting door machine device is as follows: Figure 1 to Figure 6 As shown, the running beam assembly of the rail row hoisting door machine system is processed and welded by steel plates. The walking drive system is equipped with a frequency conversion braking motor, and the operation is driven by an LDHC vertical square reducer. The outrigger assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com