Drilling simulation device and method for horizontal well drilling and reaming in tectonic coal reservoir

A simulation device and technology for coal construction, which are applied in drilling measurement, drilling automatic control system, drilling equipment, etc., can solve the problems of less simulation research, low work efficiency, low efficiency, etc., and achieve a small volume and a degree of automation. High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

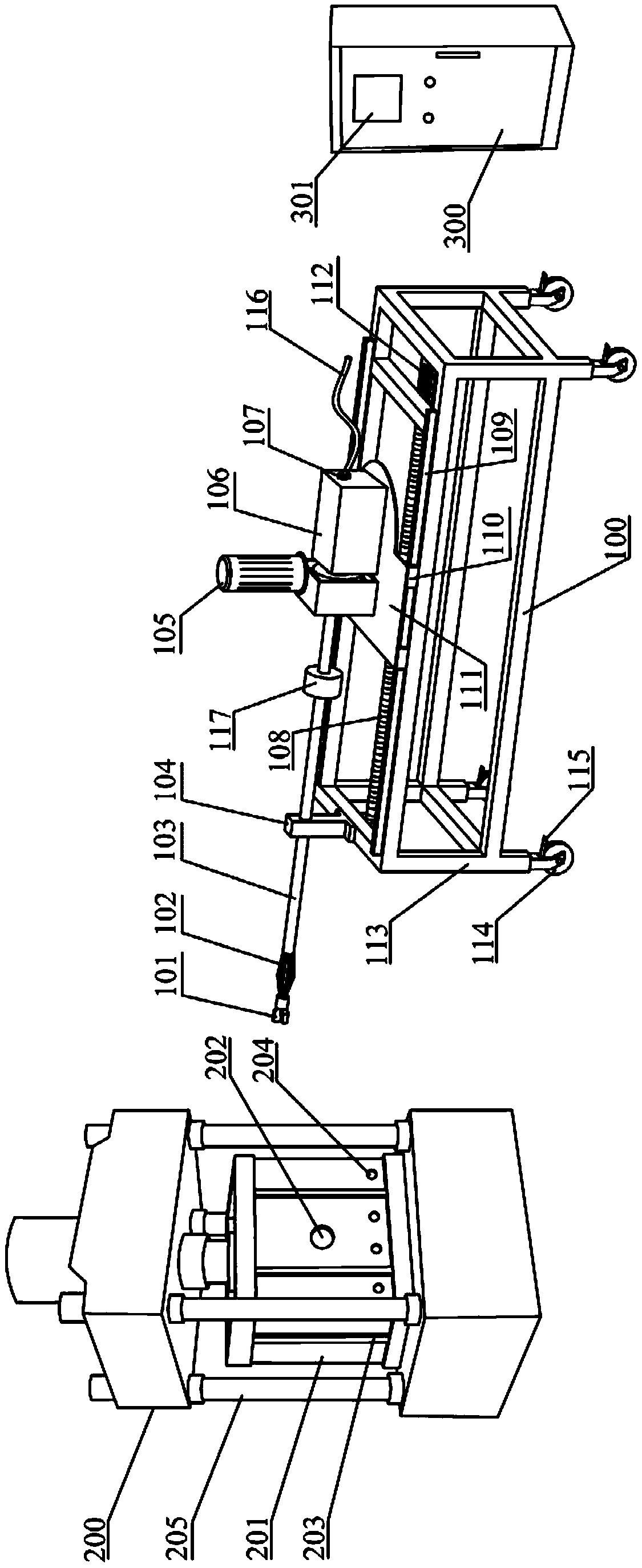

[0038] Such as figure 1 As shown, the drilling simulation device for horizontal well drilling and reaming of structural coal reservoirs of the present invention includes a drilling system 100, a coal and rock mass loading system 200 and a PLC control system 300; the drilling system 100 has a full size length×width× The height is 2000mm×800mm×1200mm;

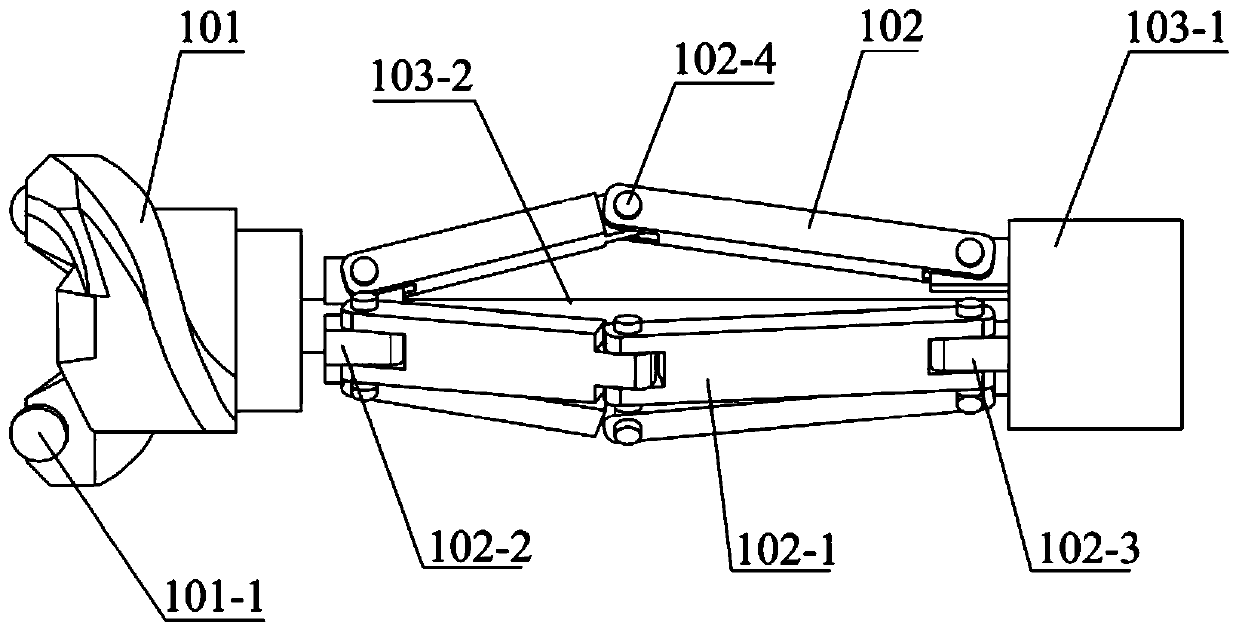

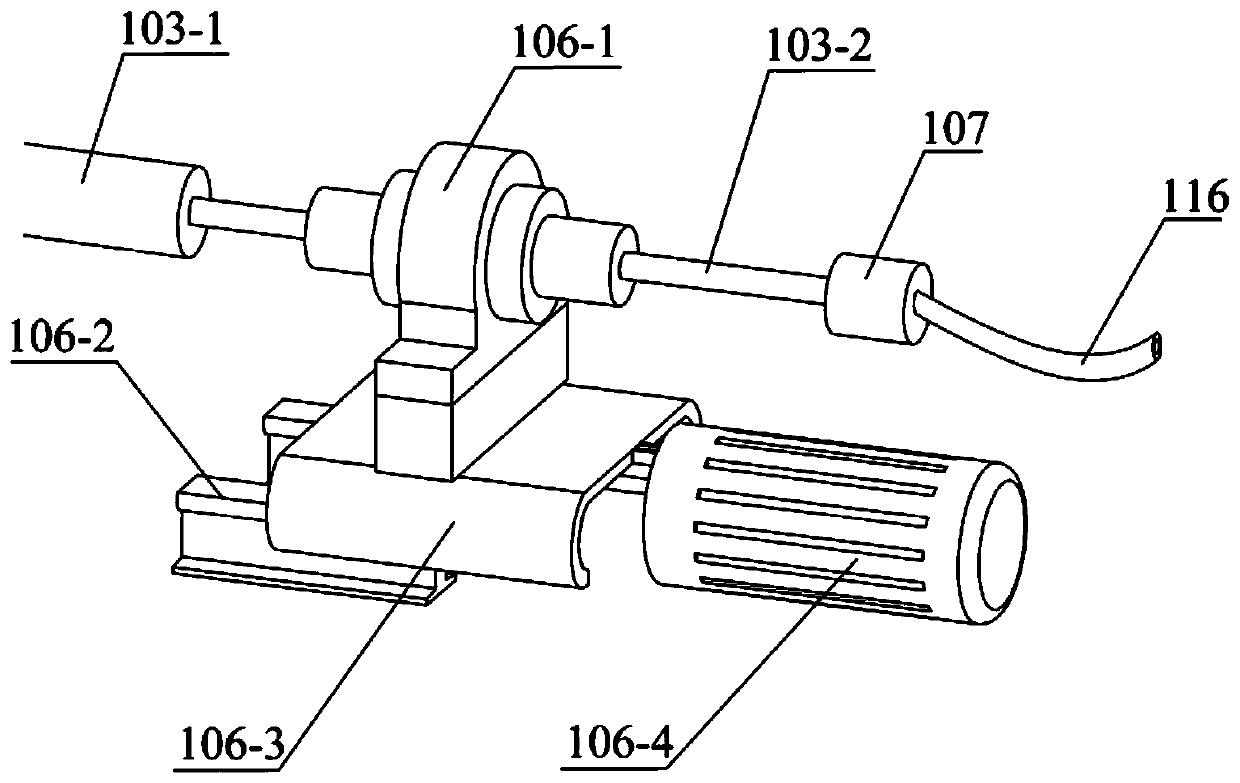

[0039] The drilling system 100 includes a drilling rig base 113. The bottom of the drilling rig base 113 is provided with a plurality of universal rollers 114, each universal roller 114 is provided with a clamp 115, and the drilling rig base 113 is provided with a square rail base 109 , The square rail base 109 is provided with four rail sliders 110, the rail sliders 110 are arranged on the left and right sides of the square rail base 109 correspondingly, and the four rail sliders 110 are provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com