A kind of composite water purifying agent and its preparation method and application

A technology of water purifier and enhancer, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of easy precipitation and fast precipitation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of composite water purifying agent:

[0023] In a 500ml beaker, add 250g of polyaluminum chloride liquid with a solid content of 45%, then add 22.5g of sodium persulfate, and stir at a constant temperature for 2 hours at 50°C under the condition of 500r / min to obtain a slurry, then mix the slurry Transfer to a rotary evaporator, evaporate and concentrate at 70°C, -0.09MPa, stop evaporating when the condensate reaches 150mL, transfer the concentrated slurry to a beaker, and obtain crystals after cooling to room temperature to obtain a composite water purifier. Named M-PAC.

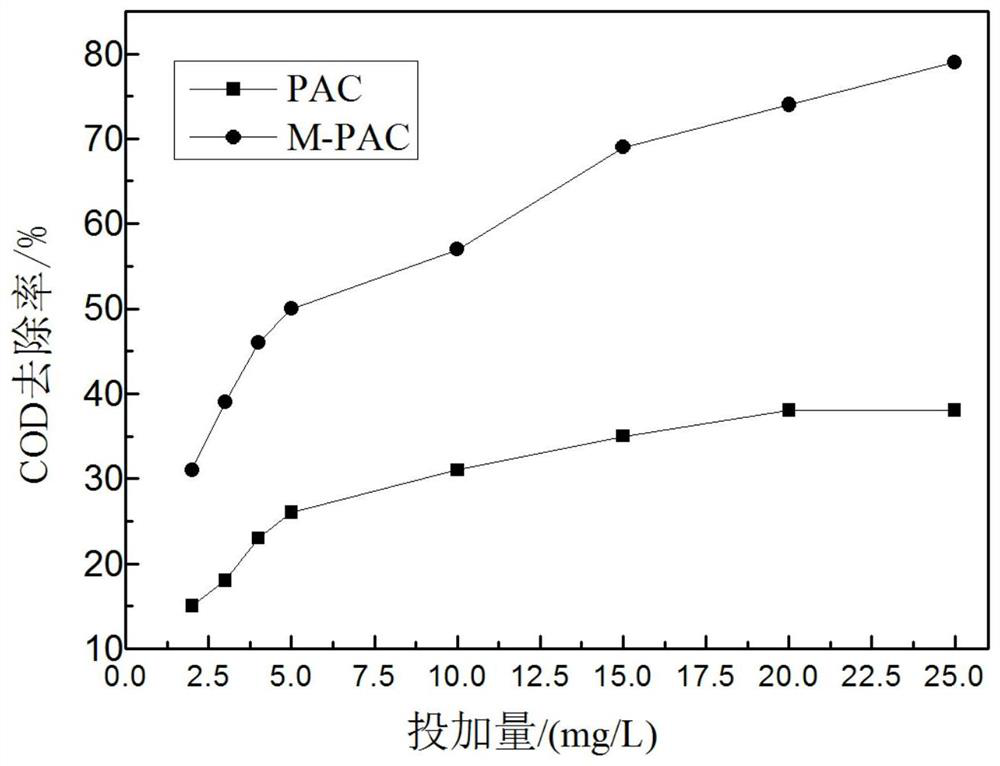

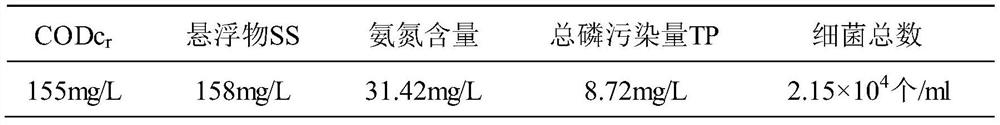

[0024] PAC comes from Henan Gongyi Fuyuan Water Purification Material Factory. The specific indicators of M-PAC obtained from the test are compared with the specific indicators of PAC, as shown in Table 1.

[0025] Table 1M-PAC and specific indicators of PAC

[0026] sample PACs M-PAC Alumina content / % 28 23 Basicity / % 82.5 86.4 pH(10g / L) 4.2...

Embodiment 2

[0031] In a 500ml beaker, add 250g of a water treatment agent polysulfide aluminum chloride liquid with a solid content of 50%, then add 30g of potassium persulfate, stir at a constant temperature for 2 hours at 60°C under the condition of 500r / min, and then transfer the slurry to On a rotary evaporator, evaporate and concentrate at 70°C, -0.085MPa. When the condensate reaches 100mL, stop evaporating, and transfer the concentrated slurry to a beaker. After cooling to room temperature, the crystal obtained is the grafted persulfate group. Agglomerated polysulfide aluminum chloride composite water purifier.

[0032]It is measured that the aluminum oxide content of the composite water purifier of this embodiment is 26%, the basicity is 83%, and the pH (10g / L) is 4.2.

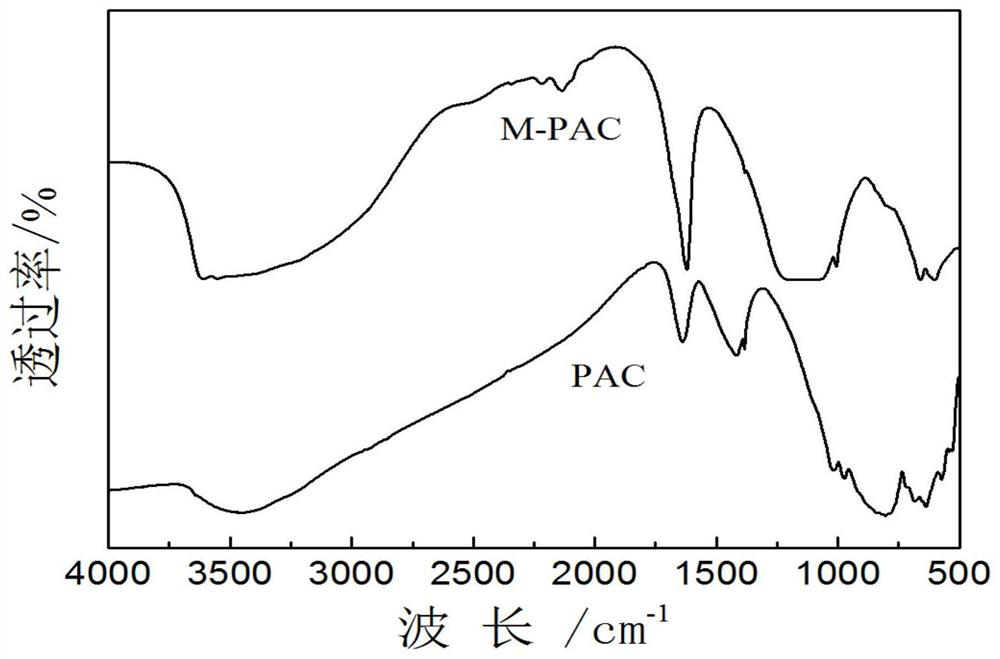

[0033] Carry out infrared spectrum test to present embodiment, and spectrogram shows at 1570cm -1 There are obvious fluctuations in the peak of the S-O group, indicating that the persulfate group has been grafted ...

Embodiment 3

[0035] In a 500ml beaker, add 250g of polyaluminum iron ferric chloride liquid with a solid content of 60%, then add 45g of sodium persulfate, and stir at a constant temperature for 2 hours at 45°C under the condition of 500r / min, then transfer the slurry to On a rotary evaporator, evaporate and concentrate at 70°C and -0.1MPa. When the condensate reaches 150mL, stop evaporating, transfer the concentrated slurry to a beaker, and obtain crystals after cooling to room temperature to obtain grafted persulfate groups. Agglomerated polyaluminium-ferric chloride composite water purifier.

[0036] It is measured that the aluminum oxide content of the composite water purifying agent of this embodiment is 35.2%, the basicity is 80.3%, and the pH (10g / L) is 4.0.

[0037] Carry out infrared spectrum test to present embodiment, spectrogram shows at 1573cm -1 There are obvious fluctuations in the peak of the S-O group, indicating that the persulfate group has been grafted on the polyalumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com