Method for separating active protein in sewage treatment process

A technology for active protein and sewage treatment, which is applied in the field of active protein separation and can solve the problem that active protein cannot be fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

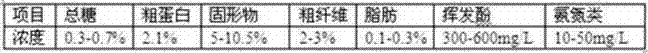

[0031] Embodiment 1 A kind of method for separating active protein in sewage treatment process, comprises the following steps:

[0032] 1. Sedimentation in a settling tank

[0033] The sewage is introduced into a settling tank. According to the characteristics of high pollution concentration and fast sedimentation rate of sewage, natural sedimentation is used to remove suspended solids with a mass fraction of 70-80% and COD with a mass fraction of 8%-12%.

[0034] 2. Treatment in the adjustment pool

[0035] The sewage is introduced into the adjustment tank, and the pH value of the sewage is adjusted with soda ash, and the pH value is 7.0, which is conducive to improving the activity of anaerobic bacteria under this condition.

[0036] 3. UASB reactor treatment

[0037] The treated sewage in the regulating tank enters the reactor through the bottom of the UASB reactor, and the sewage flows upward through the sludge bed area to contact with a large number of anaerobic bacteri...

Embodiment 2

[0049] Embodiment 2 A kind of method for separating active protein in sewage treatment process

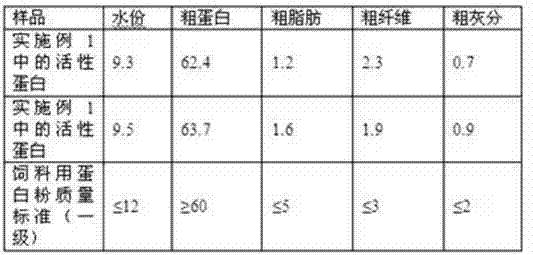

[0050] The active protein in the sludge that obtains in embodiment 1 step 5 is separated:

[0051] (1) Transfer 500g of the sludge obtained in step 5 to a beaker, add 500g of water and stir for 3 minutes to obtain a sludge suspension with a mass fraction of 80% water, and then settle for 30 minutes. Among them, fungi, Active proteins such as algae will float on the upper layer of the liquid surface, and the upper layer of the sludge tank is taken to obtain 720g of active protein slurry. The mass fraction of dry matter contained in the active protein slurry is 5.2%.

[0052] (2) Filter the active protein slurry obtained in step (1) with filter paper to obtain 363.5 g of a material with a dry matter content of 10.3%.

[0053] (3) Put the material obtained in step (2) into a beaker, add water to the beaker, and stir to obtain 913.2 g of the material, with a mass fraction of dry matte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com