Integrated device and method for efficient magnesium ammonium phosphate crystallization and solid-liquid separation

A solid-liquid separation, magnesium ammonium phosphate technology, applied in separation methods, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low processing capacity, low ammonia phosphorus recovery rate, incomplete solid-liquid separation of MAP crystals, etc. The effect of simplifying equipment, efficient solid-liquid separation, avoiding secondary pollution and waste of crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

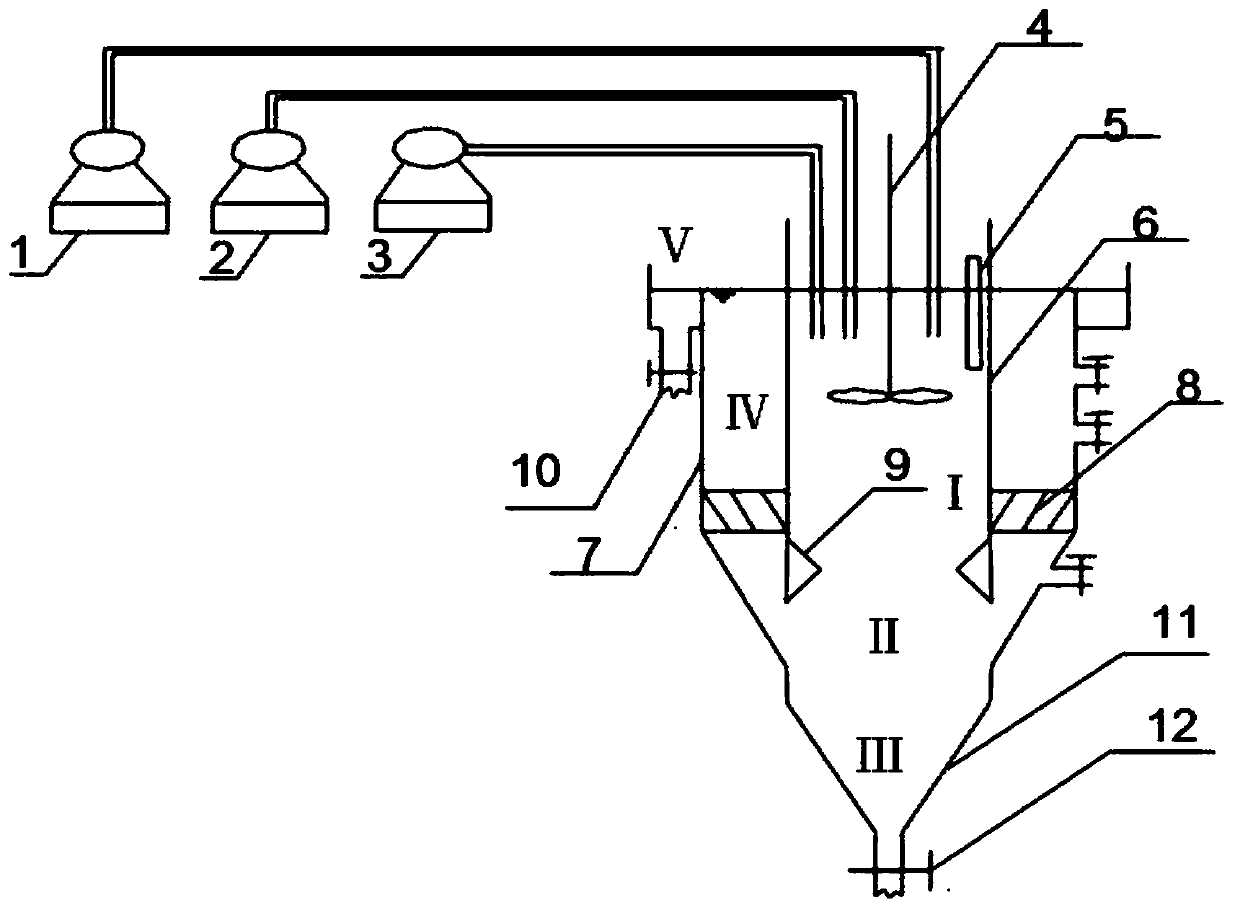

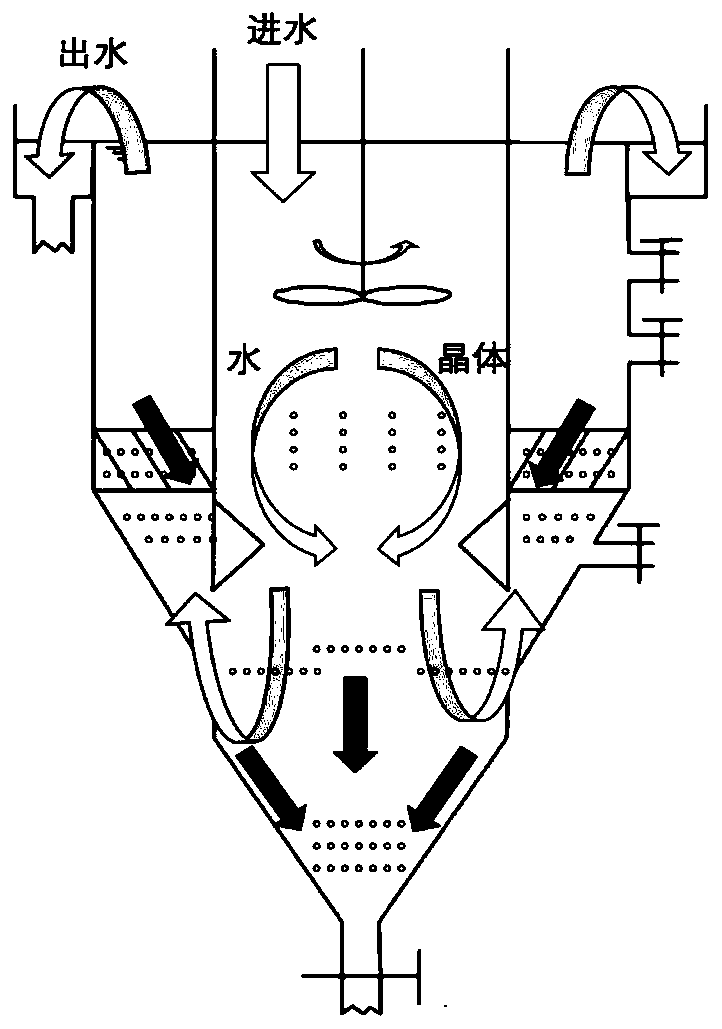

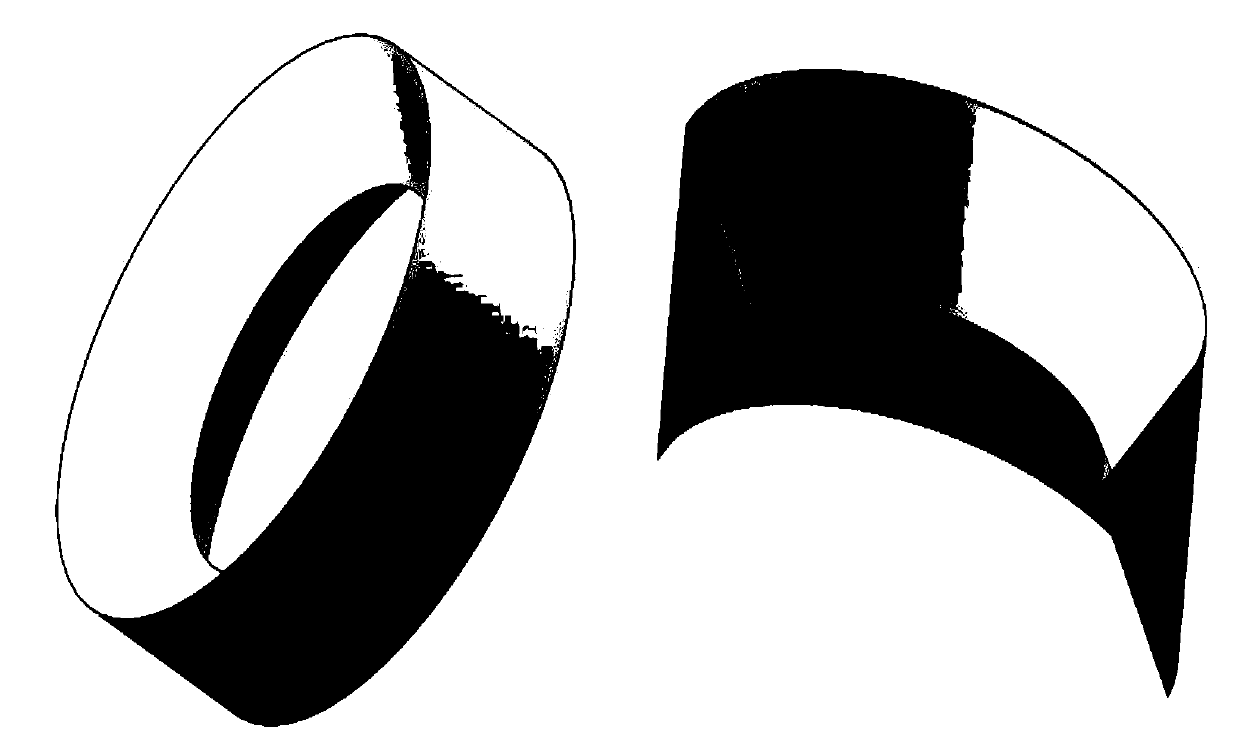

[0036] as attached figure 1 As shown, the MAP crystallization reactor device of the present invention comprises: 1-nitrogen and phosphorus waste water inlet pump; 2-magnesium source water inlet pump; 3-lye liquor inlet pump; 4-mechanical stirrer; 5-pH meter; 6-inner cylinder wall ;7-outer cylinder wall; 8-sloping plate; 9-ring type V-type solid-liquid two-phase separator; 10-water outlet; 11-conical mud bucket; 12-MAP crystal discharge valve; I-mixed reaction crystallization area ; II-buffer zone; III-MAP sludge zone; IV-solid-liquid separation zone; V-outlet zone. Mixed reaction crystallization zone (I) links to each other with nitrogen and phosphorus wastewater inlet water pump (1), magnesium source water inlet pump (2), lye inlet water pump (3), and is provided with mechanical stirrer (4) and pH meter ( 5), the buffer zone (II) is connected to the mixed reaction crystallization zone (I), and is arranged at the lower part of the mixed reaction crystallization zone (I), and ...

Embodiment 2

[0039] The operating method of magnesium ammonium phosphate crystallization reclaiming nitrogen and phosphorus among the present invention: by pump (1) suction n(PO 4 3- ):n(NH 4 + ) is 1:1 phosphorus and ammonium mixed wastewater in the inner cylinder mixed reaction crystallization zone (I), and at the same time through the pump (2, 3) suction magnesium source and the lye required for the reaction in the inner cylinder mixed reaction crystallization zone ( In I), control n(Mg 2+ ): n(PO 4 3- ) at 1:1, control the influent flow rate at 24.8L / h, turn on the agitator (4), rotate at 350r / min, and control the pH value of the reaction at 9.5 (±0.2) through the pH meter (5) to carry out the crystallization reaction . After the reaction, the waste water carries crystals into the buffer zone (II) first, and the settled crystals fall into the MAP sludge area (III), and the sludge discharge valve (12) at the bottom of the MAP sludge area (III) is fixed every 0.5h to discharge 1L ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com