Method and system for treating ethylene tar

A kind of technology of ethylene tar and treatment method, which is applied in the direction of treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc., and can solve the problems of shortening the operation period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

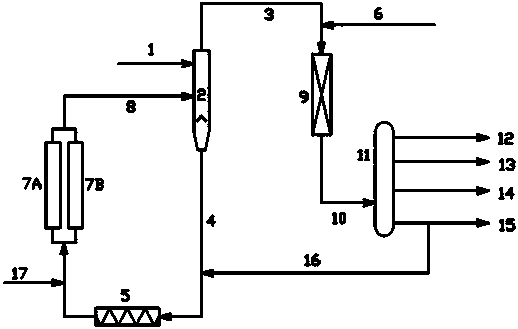

Method used

Image

Examples

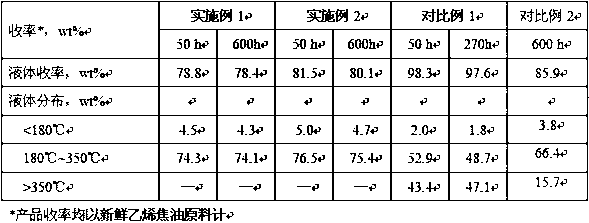

Embodiment 1

[0057] Example 1 Using the treatment system and treatment method of the present invention, ethylene tar is contacted with the delayed coking reaction effluent in a pretreatment reactor to separate light components and heavy components. The light component enters the hydrogenation reaction system for hydrogenation reaction. According to the flow direction of the material, the hydrogenation reactor is filled with FZC-102B, FZC-103, FF-26 and FF-46 catalysts produced by Fushun Petrochemical Research Institute in sequence. After the product is separated, gas, gasoline fraction, diesel fraction and heavy oil fraction are obtained; the heavy fraction and heavy oil fraction are mixed and sent to the delayed coking reaction system, and AlCl is injected into the pipeline before entering the tower 3 The aqueous, coking reaction effluent enters the pretreatment reactor. The specific operating process conditions are listed in Table 2, and the liquid product distribution is listed in Table...

Embodiment 2

[0060] Example 2 Using the treatment system and method of the present invention, ethylene tar is contacted with the delayed coking reaction effluent in a pretreatment reactor to separate light components and heavy components. The light component enters the hydrogenation reaction system, and passes through FZC-102B, FZC-103, FF-26 and FF-46 catalysts in sequence in the hydrogenation reactor, and the reaction products are separated to obtain gas, gasoline fraction, diesel fraction and heavy oil fraction; recombination The fraction and the hydrogenated heavy oil fraction are mixed and sent to the delayed coking reaction system, and AlCl is injected into the pipeline before entering the tower 3 The aqueous, coking reaction effluent enters the pretreatment reactor. The specific operating process conditions are listed in Table 2, and the liquid product distribution is listed in Table 3. After the device was running for 600 hours, the reaction was stopped, and the FF-26 catalyst in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com