Composite material formed building template

A technology of building formwork and composite materials, which is applied in the direction of architecture, building structure, formwork/formwork components, etc., can solve the problems of underutilized heat from collectors, not very fresh indoor air, and no ventilation system, etc., to achieve Simplify the building construction process, have no pollution and side effects, and save the effect of release agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

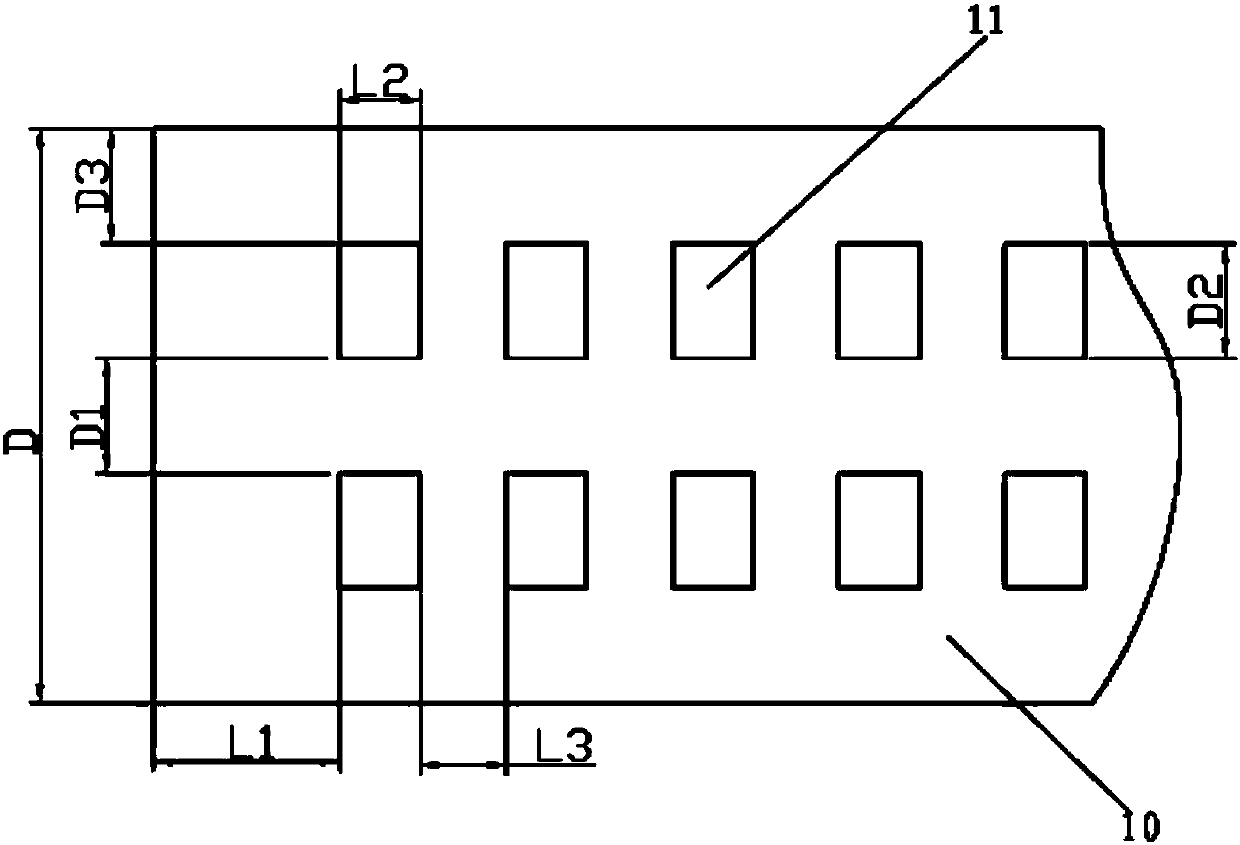

[0010] see figure 1 , a composite material molding building template 10, made of recycled PVC as the main raw material through mixing, extrusion, fixed mold forming and other processes. The building template 10 has a specification of 20×300×20mm, that is, the thickness D is 20mm, the length is 300mm, and the width is 20mm. There are two rows of through-holes 11 penetrating through the width direction in the center along the length direction. The size of the through-holes is 2.8×4mm, that is, the width L2 is 2.8mm, and the length D2 is 4mm. Each row is provided with 50 through holes 11 , the distance D1 between each row of through holes 11 is 4 mm, and the distance D3 between each row of through holes 11 and the long side is 4 mm. The distance L3 between the through holes 11 in the same row is 3 mm, and the distance L1 between the through holes 11 at both ends of each row and the short side is 6.5 mm.

[0011] The above content is a further detailed description of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com