Ragweed pollen allergen extract, ragweed pollen allergen extraction liquid and preparation method of extract

A technology of allergens and extracts, which is applied in the direction of allergen antigen components, pharmaceutical formulations, powder delivery, etc., can solve the problems of protein content and biological potency decrease, positive rate decrease, poor stability, etc., to avoid detection Effects of false positives, improved stability, and short cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

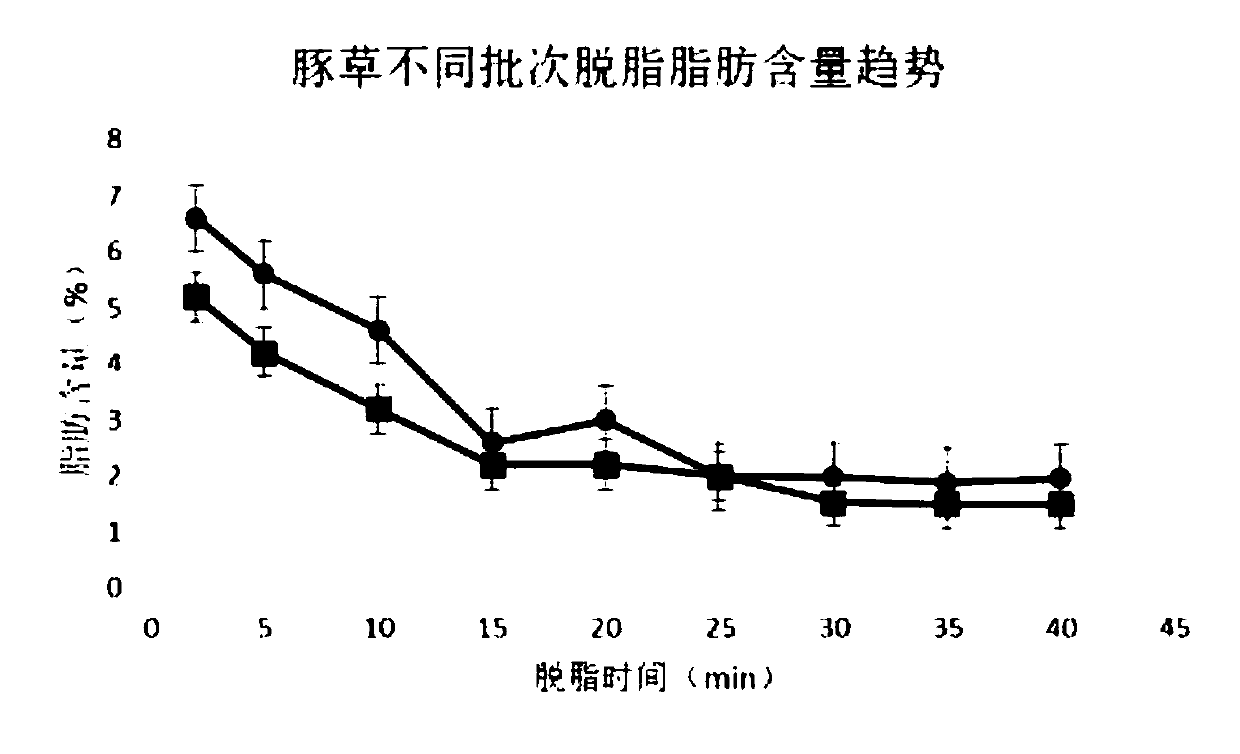

[0086] Example 2 Degreasing of ragweed pollen and determination of important parameters in key process steps of extraction

[0087] 1. Degreasing process parameters of ragweed pollen

[0088] (1) The ragweed pollen (g) and acetone (ml) were degreased at a weight-to-volume ratio (w / v) of 1:2. The fat content of different batches (different collection time) of ragweed pollen with different defatting time samples was tested to determine the optimal defatting time.

[0089] The fat content of ragweed pollen was measured by the Sea Energy SOX500 fat analyzer, and the weight change of the pollen before and after extraction was compared by Soxhlet extraction and dry weighing method to obtain the corresponding fat content, and the fat content was compared with the fat content after degreasing Pollen for quality control.

[0090] see results figure 2 , it can be seen that after the acetone degreasing time is 30min, the fat content hardly decreases with the prolongation of the degre...

Embodiment 3

[0101] Embodiment 3 ragweed pollen raw material technology

[0102] 1. Pollen collection

[0103] Collect ragweed pollen by natural shedding. Normal temperature or vacuum or fluidized bed drying, until the pollen no longer sticks. Pass the dried pollen through a 150-250 mesh sieve, preferably a 180 mesh sieve in this embodiment.

[0104] 2. Dry

[0105] Spread the pollen in a ventilated and dry place to dry naturally, or vacuum dry, or dry in a fluidized bed for 6-48 hours, until the pollen no longer adheres.

[0106] 3. Degreasing

[0107] The pollen (g) obtained above and acetone (ml) are subjected to degreasing treatment at a weight-to-volume ratio (w / v) of 1:5-1:1. In this embodiment, it is preferably 1:2. Stir or oscillate to degrease for 30 minutes, let stand to separate layers, and observe the clarification of the upper liquid. Pour out the upper layer, add new acetone, and repeat degreasing until the upper layer is clear.

[0108] 4. Dry again

[0109] Spread ...

Embodiment 4

[0116] Embodiment 4 Preparation process of ragweed pollen allergen stock solution (lyophilized product)

[0117] 1, according to embodiment 3 ragweed pollen raw material process preparation ragweed pollen raw material.

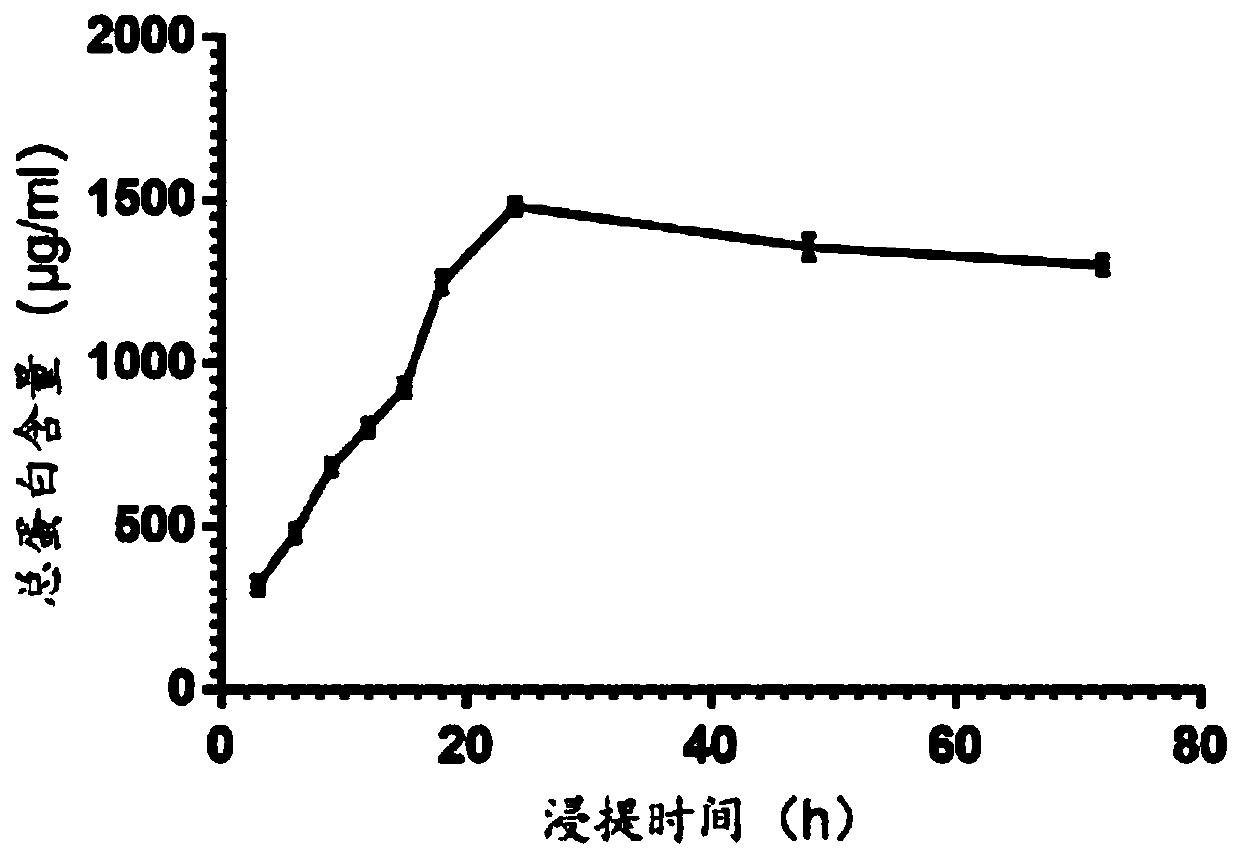

[0118] 2. Leaching

[0119] Add the defatted and dried ragweed pollen to 10 L at a weight-to-volume ratio of 1:50 to 1:10, preferably 1:20 in this example, and stir in pH 7.9 to 8.2 phosphate-saline buffer solution at 2 to 8°C for 22 ~26h for leaching. Wherein, the formula of preparing 1000ml phosphate-saline buffer (pH 8.2) as an example is shown in Table 4. Phosphate-saline buffer solution is fully dissolved, sterilized and filtered, placed at 2-8°C, and the storage period does not exceed 30 days.

[0120] Table 4 Phosphate-saline buffer (pH 8.2) formulation

[0121]

[0122] 3. Solid-liquid separation

[0123] Take the extracted extract, add all the extract into the centrifuge bucket, adjust the balance, centrifugal force 8000-12000g, centrifuge tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com