Cow dung disposal system

A treatment system and cow dung technology, applied in the direction of biological sludge treatment, gas fuel, waste fuel, etc., can solve the problems of high operating cost, need special personnel on duty, and high investment cost of equipment, so as to improve desulfurization efficiency and benefit desulfurization , Contribute to the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

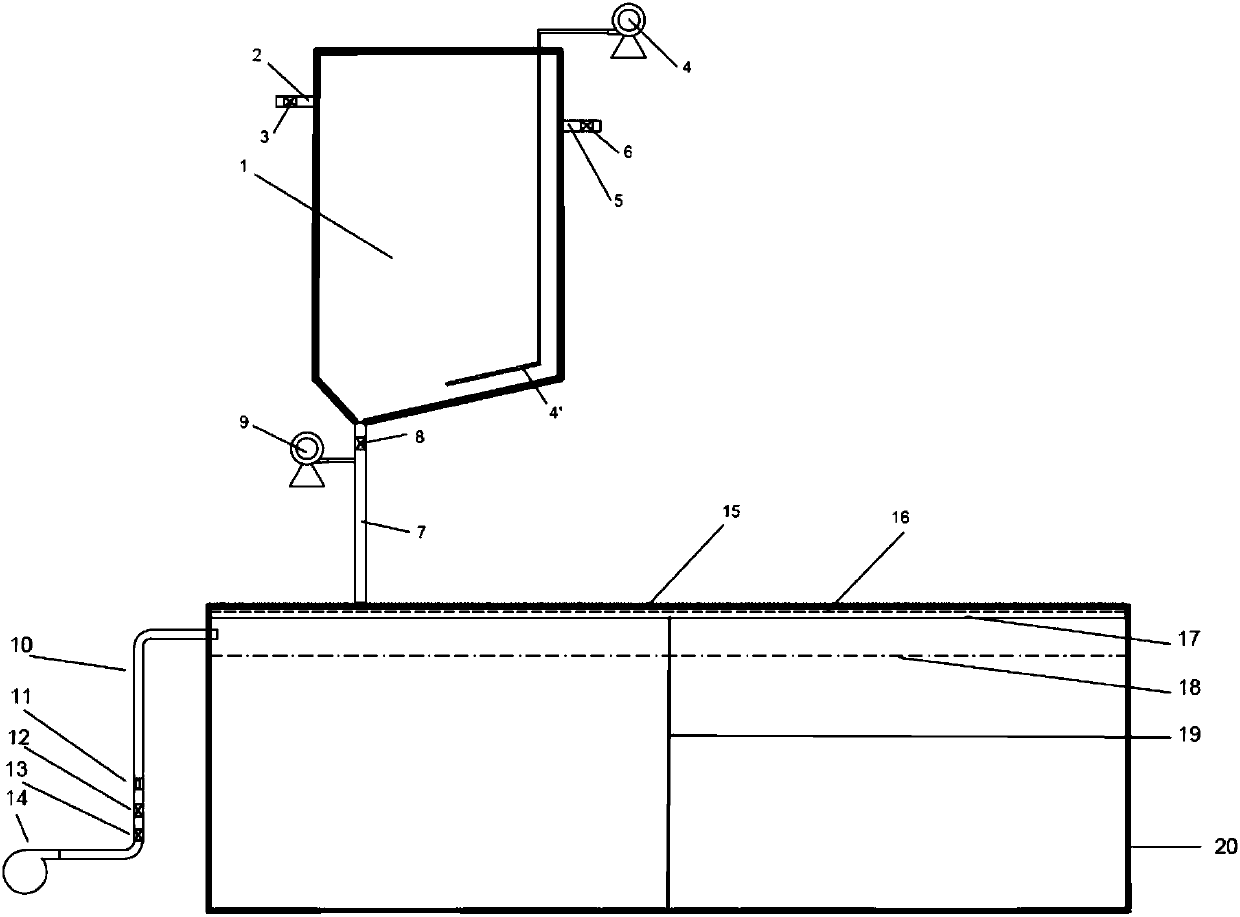

[0019] Such as figure 1 As shown, the present invention provides a kind of cow dung treatment system, comprises cow dung purification device and cow dung utilization device;

[0020] The cow dung purification device comprises a first tank body 1, the bottom of the first tank body 1 is funnel-shaped, the first tank body 1 is provided with a sample inlet pipe 2, an outlet pipe 5 and a sample outlet pipe 7, and the inlet The sample pipe 2 is provided with a valve 3, the outlet pipe 5 is provided with a valve 6, and the sample outlet pipe 7 is provided with a valve 8; the sample outlet pipe 7 is connected with the first air pump 9; the first tank The inside of the body 1 is provided with a porous tube 4', and the porous tube 4 is connected to the second air pump 7 outside the first tank body 1 through an air guide tube; In the upper part, the sample outlet pipe 7 is placed in the lower part of the first tank body 1; the position of the sample inlet pipe 2 is higher than that of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com