Heat-resistant rubber water-stop belt for high geothermal areas

A technology of heat-resistant rubber and water-stop, which is applied in the field of heat-resistant rubber water-stop, which can solve the problems that the water-stop cannot meet the needs of water-stop parts, lose waterproof function, and accelerate aging, so as to reduce the decline of mechanical properties , not easy to volatilize and decompose, and improve the effect of heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

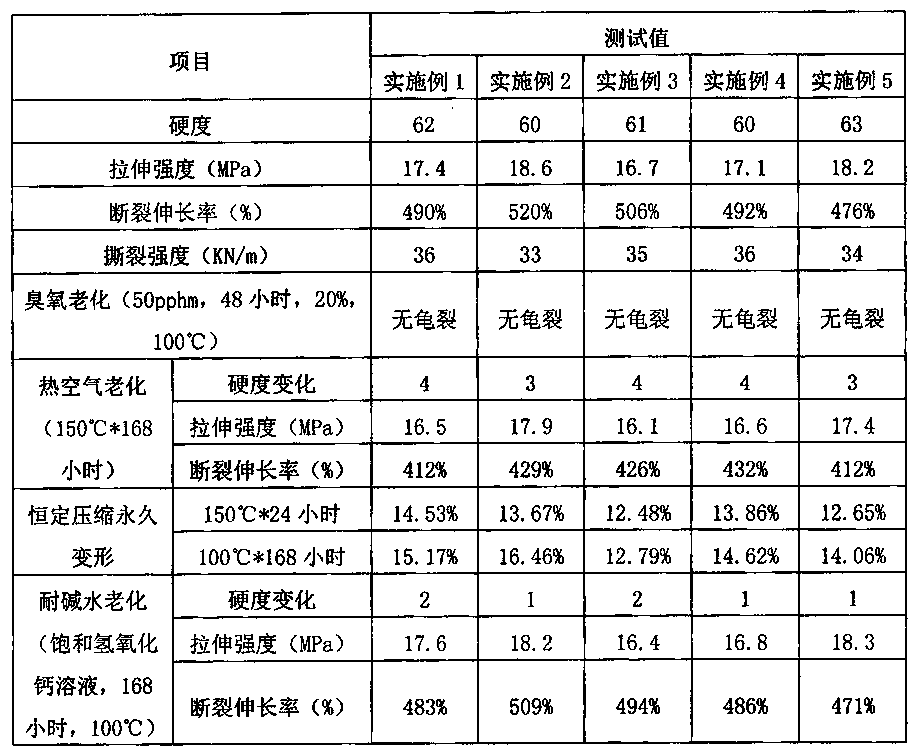

Examples

Embodiment 1

[0035] 80 parts by weight of ethylene-propylene rubber 3200A, 20 parts by weight of chlorinated polyethylene, 5 parts by weight of zinc oxide, 3 parts by weight of stearic acid, and 0.4 parts by weight of antioxidant are put into the internal mixer and mixed for 50 seconds, then 40 parts by weight Parts by weight of carbon black N330, 10 parts by weight of magnesium oxide, 10 parts by weight of silicon dioxide, and 10 parts by weight of plasticizer are put into the internal mixer, mixed for 140 seconds, discharged to the open mixer, and added after cooling down through the thin pass 2 parts by weight of dicumyl peroxide (DCP) and 1 part by weight of auxiliary cross-linking agent TAIC, mixed evenly and then tableted.

[0036] The mixed rubber material is extruded by a single-screw extruder and then vulcanized by a vulcanization box. The temperature of the screw and barrel is set at 60°C, and the temperature of the vulcanization box is set at 220°C.

Embodiment 2

[0038] Put 90 parts by weight of ethylene propylene rubber 2070P, 10 parts by weight of chlorinated polyethylene, 6 parts by weight of zinc oxide, 2.5 parts by weight of stearic acid, and 0.5 parts by weight of antioxidant into an internal mixer for mixing for 60 seconds, then 50 parts by weight Parts by weight of carbon black N550, 8 parts by weight of magnesia, 15 parts by weight of attapulgite, and 8 parts by weight of plasticizer are put into the internal mixer, mixed for 160 seconds, discharged to the open mixer, and added after cooling down through the thin pass 2.5 parts by weight of dicumyl peroxide (DCP) and 0.4 parts by weight of auxiliary cross-linking agent sulfur, mixed evenly and then tableted.

[0039] The mixed rubber is extruded by a single-screw extruder and then vulcanized by a vulcanization box. The temperature of the screw and barrel is set at 70°C, and the temperature of the vulcanization box is set at 240°C.

Embodiment 3

[0041] Put 85 parts by weight of ethylene propylene rubber 8550, 15 parts by weight of chlorinated polyethylene, 4.5 parts by weight of zinc oxide, 4 parts by weight of stearic acid, and 0.5 parts by weight of antioxidant into a banbury mixer for 50 seconds, and then 50 parts by weight Parts by weight of carbon black N550, 8 parts by weight of silicon dioxide, 12 parts by weight of attapulgite, and 9 parts by weight of plasticizer are put into the internal mixer, mixed for 160 seconds, and discharged to the open mixer. Add 2 parts by weight of dicumyl peroxide (DCP) and 1 part by weight of auxiliary crosslinking agent TAC, mix evenly and then release the tablet.

[0042] The mixed rubber is extruded by a single-screw extruder and then vulcanized by a vulcanization box. The temperature of the screw and barrel is set at 80°C, and the temperature of the vulcanization box is set at 220°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com