Ecological photo-catalytic fireproof coating for air purification and preparation method of ecological photo-catalytic fireproof coating

A technology for fire-resistant paint and air purification, applied in fire-resistant paint, coating and other directions, can solve the problems of high cost, single function of paint filler, complex process, etc., and achieve the effect of reducing production cost and improving market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

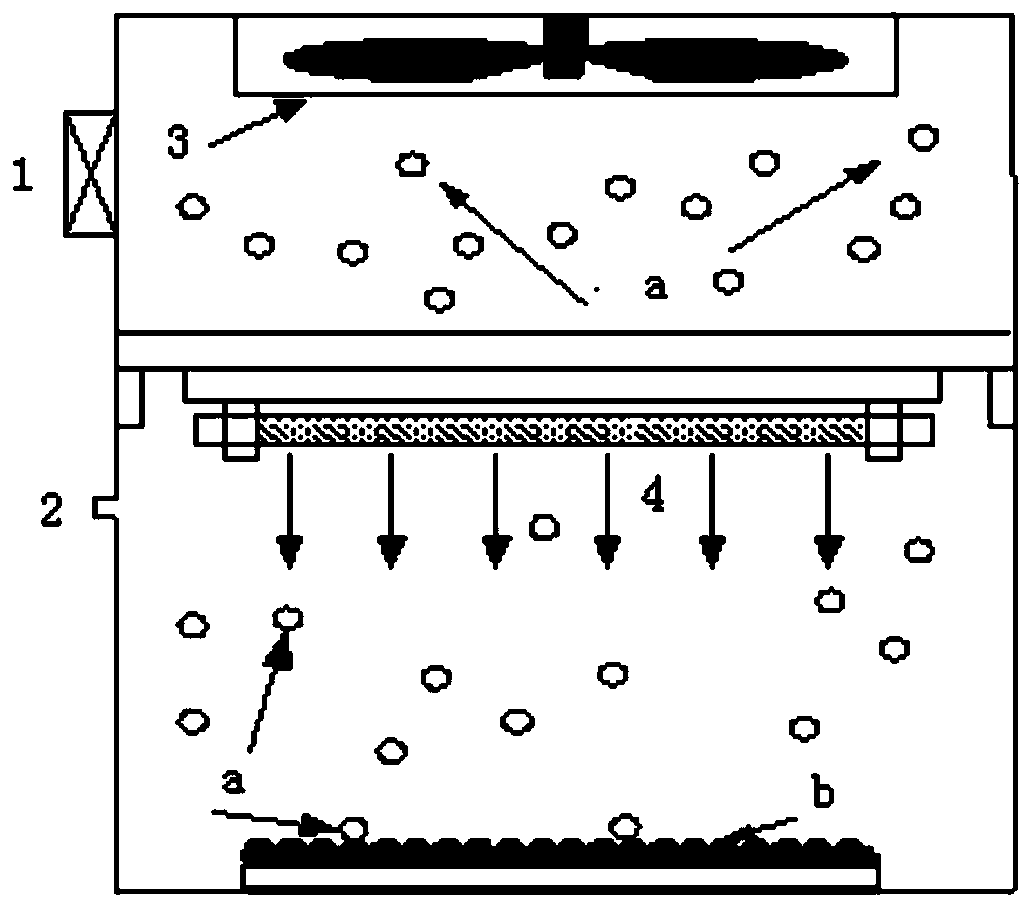

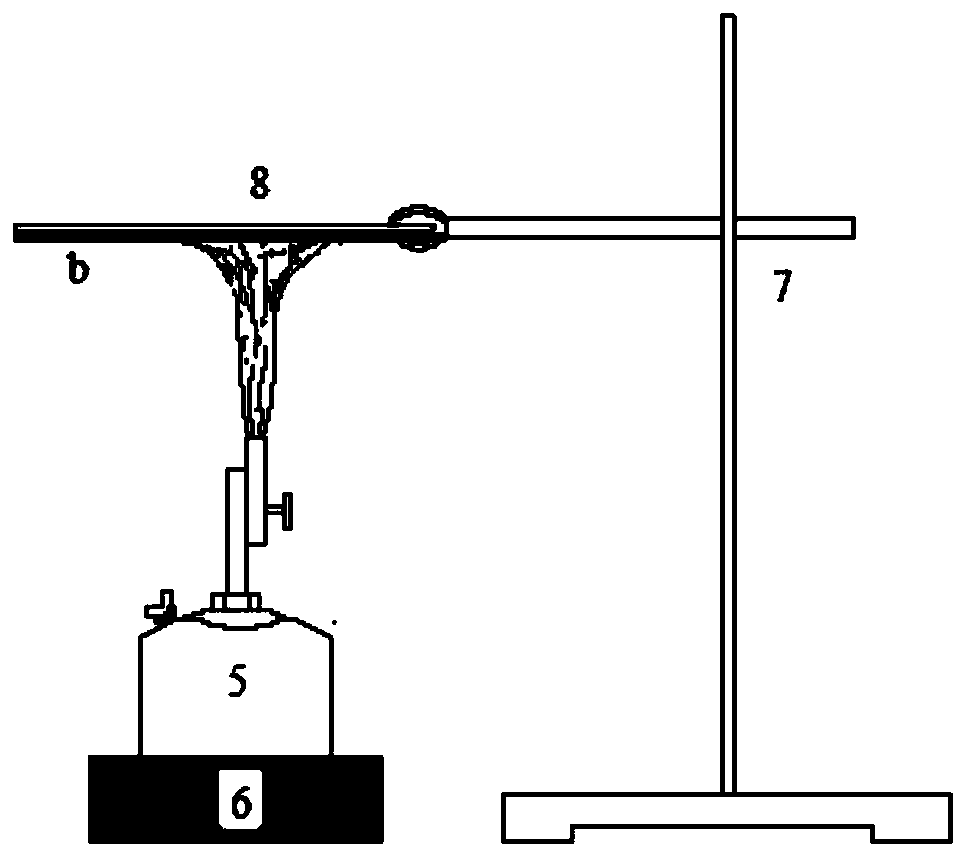

Image

Examples

Embodiment 1

[0025] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0026]

[0027] The base material is aluminum dihydrogen phosphate; the catalyst is ammonium polyphosphate; the char-forming agent is dipentaerythritol; the foaming agent is melamine; the flame-retardant filler is Bayer red mud powder; The photocatalytic pigment is steel slag modified TiO 2 The inorganic solvent is water; the dispersant is sodium hexametaphosphate; the drying agent is manganese dioxide; the drying aid is zinc powder; the nano mother liquor is nano SiO 2 mother liquor.

[0028] Firstly, according to the volume ratio of tetrabutyl titanate and absolute ethanol in a ratio of 1:3, stir with a constant temperature magnetic stirrer at 600r / min for 40min to obtain a uniform transparent solution, and then dissolve the dilute hydrochloric acid solution with steel slag fine powder at 1000r Slowly add the above solution under th...

Embodiment 2

[0032] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0033]

[0034]

[0035] The base material is aluminum dihydrogen phosphate; the catalyst is ammonium polyphosphate; the char-forming agent is dipentaerythritol; the foaming agent is melamine; The catalytic pigment is steel slag modified TiO 2 The inorganic solvent is water; the dispersant is sodium hexametaphosphate; the drying agent is manganese dioxide; the drying aid is zinc powder; the nano mother liquor is nano SiO 2 mother liquor.

[0036] Firstly, according to the volume ratio of tetrabutyl titanate and absolute ethanol in a ratio of 1:3, stir with a constant temperature magnetic stirrer at 700r / min for 30min to obtain a uniform transparent solution, and then dissolve the dilute hydrochloric acid solution with steel slag fine powder at 800r Slowly add the above solution under the condition of 1000r / min and stir for 55min un...

Embodiment 3

[0040] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0041]

[0042]

[0043] The base material is aluminum dihydrogen phosphate; the catalyst is ammonium polyphosphate; the char-forming agent is dipentaerythritol; the foaming agent is melamine; The photocatalytic pigment is steel slag modified TiO 2 The inorganic solvent is water; the dispersant is sodium hexametaphosphate; the drying agent is manganese dioxide; the drying aid is zinc powder; the nano mother liquor is nano SiO 2 mother liquor.

[0044] Firstly, according to the volume ratio of tetrabutyl titanate and absolute ethanol in a ratio of 1:3, stir with a constant temperature magnetic stirrer at 800r / min for 45min to obtain a uniform transparent solution, and then dilute hydrochloric acid solution with steel slag powder dissolved at 900r Slowly add the above solution under the condition of 800r / min and stir for 60min under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com