A cold start system and its control method

A control method and cold start technology, applied in battery/fuel cell control devices, electric vehicles, final product manufacturing, etc., can solve problems such as stack leakage, permanent burnout of membrane electrodes, and low oxidant fuel flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

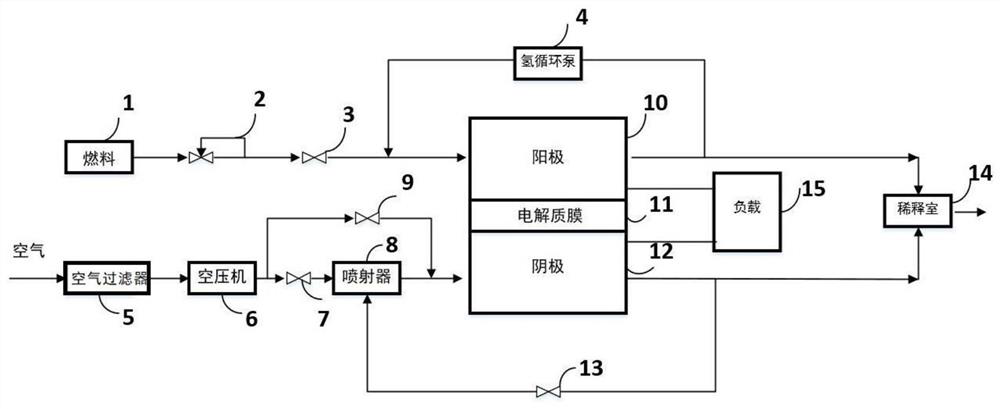

[0037]In a fuel cell vehicle powered by a fuel cell system, starting the fuel cell at low temperature has always been a research hotspot. In the prior art, the method of heating the fuel cell by adding additional energy or changing the internal resistance of the fuel cell is generally used to increase the fuel cell temperature. battery temperature, but these methods will have some impact on fuel utilization efficiency or safety and convenience, and are not a good choice. This embodiment provides a cold start system, which includes a fuel reactor and a fuel supply pipeline , an oxidant supply pipeline, a temperature sensor and a controller; the fuel supply pipeline communicates with the fuel reactor stack for delivering fuel to the anode 10 of the fuel reactor stack; the oxidizer supply pipeline communicates with the fuel reactor stack The fuel reactor stack communicates for delivering oxidant to the cathode 12 of the fuel reactor stack, and the oxidant supply line includes an i...

Embodiment 2

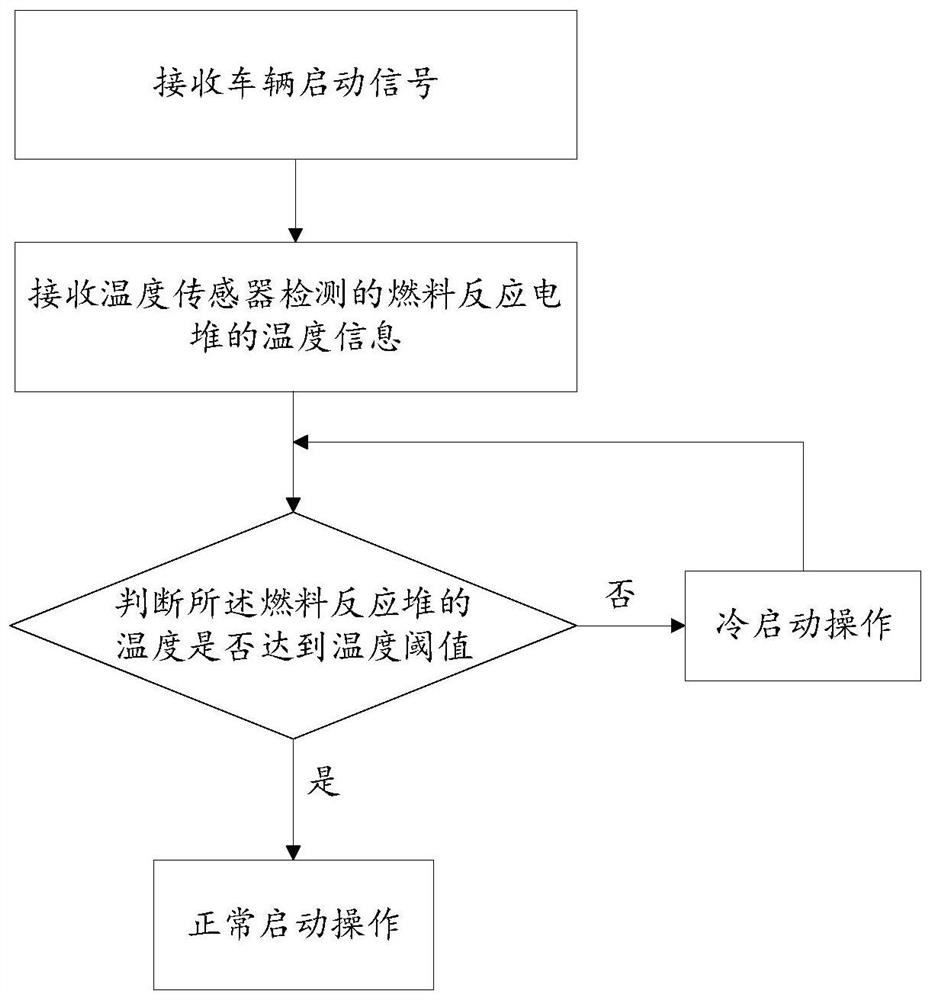

[0049] This embodiment proposes a control method for a cold start system on the basis of Embodiment 1, including the following steps:

[0050] Receive vehicle start signal;

[0051] receiving the temperature information of the fuel reactor stack detected by the temperature sensor;

[0052] Judging whether the temperature of the fuel reactor reaches a temperature threshold, if so, controlling the system to perform a cold start operation to increase the temperature of the fuel reactor; if not, controlling the system to perform a normal start operation.

[0053] Specifically, when the driver starts the vehicle, the controller receives the start signal and controls the temperature sensor to work. The temperature sensor detects the temperature information of the fuel reactor. Analyze the control flow of the next step.

[0054] The cold start operation includes the following steps: the controller controls the pressure control valve 2 and the flow control valve 3 to reduce the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com