High-strength and corrosion-resistant Al-Mg-Zr aluminum alloy welding stick and preparation method thereof

An aluminum alloy welding wire, corrosion-resistant technology, applied in welding equipment, metal processing equipment, welding medium, etc., to ensure smooth implementation, low thermal cracking tendency, and good formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

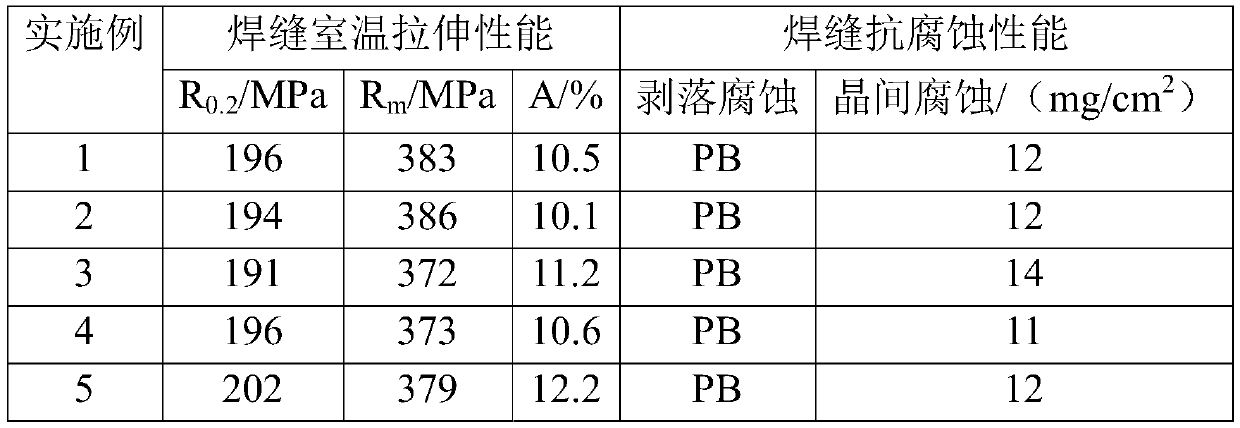

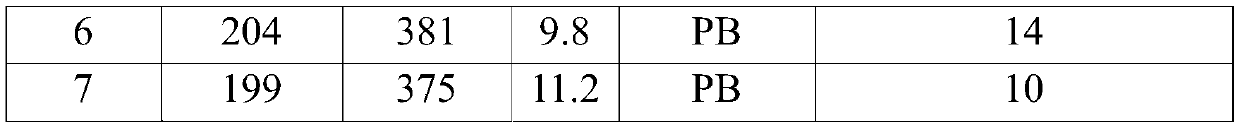

Examples

Embodiment

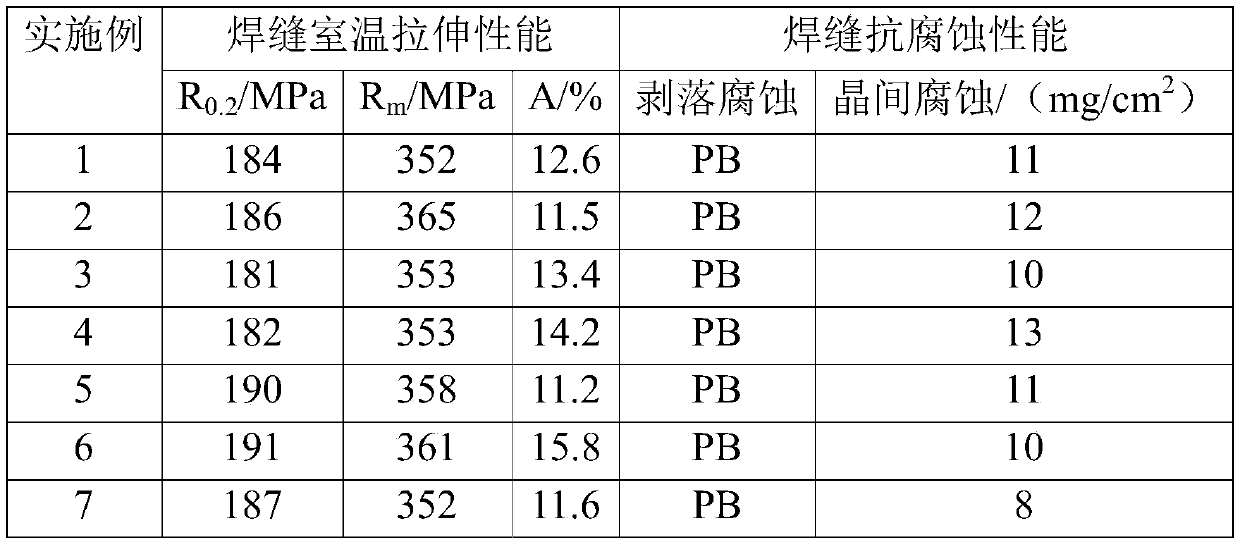

[0033] Table 1 shows the mass percentages of alloy elements in the high-strength corrosion-resistant aluminum alloy welding wire proposed by the present invention.

[0034] Table 1 Mass percentage of alloying elements

[0035] Example Mg Zr mn Ti sc Ag be Y Fe Si 1 6.1 1.2 0.8 0.02 0.05 0.3 0.0003 0.002 0.03 0.02 2 6.4 1.0 1.0 0.02 0.08 - 0.0003 0.002 0.05 0.01 3 6.8 1.0 0.6 0.03 0.02 0.4 0.0003 0.003 0.03 0.01 4 5.6 0.8 0.5 0.05 - 0.4 0.0002 0.002 0.03 0.02 5 5.8 1.0 0.9 0.02 - - 0.0002 0.003 0.02 0.02 6 6.5 1.1 0.8 0.03 0.10 0.5 0.0003 0.003 0.05 0.01 7 5.9 1.2 1.1 0.03 0.12 - 0.0003 0.002 0.03 0.02

[0036] The implementation is as follows:

[0037] Raise the temperature in the atomization furnace to melt the raw materials except Mg, and then atomize it into powder at a temperature of 950-1050°C. Remove the particles above 150 mesh from the atomi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com