Composition for forming flame retardant silicone rubber and flame retardant silicone rubber

A composition and technology of silicone rubber, applied in the field of flame retardant silicone rubber, can solve problems such as poor flame retardant performance, and achieve the effects of protecting from damage, isolating external flames, enhancing strength and structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

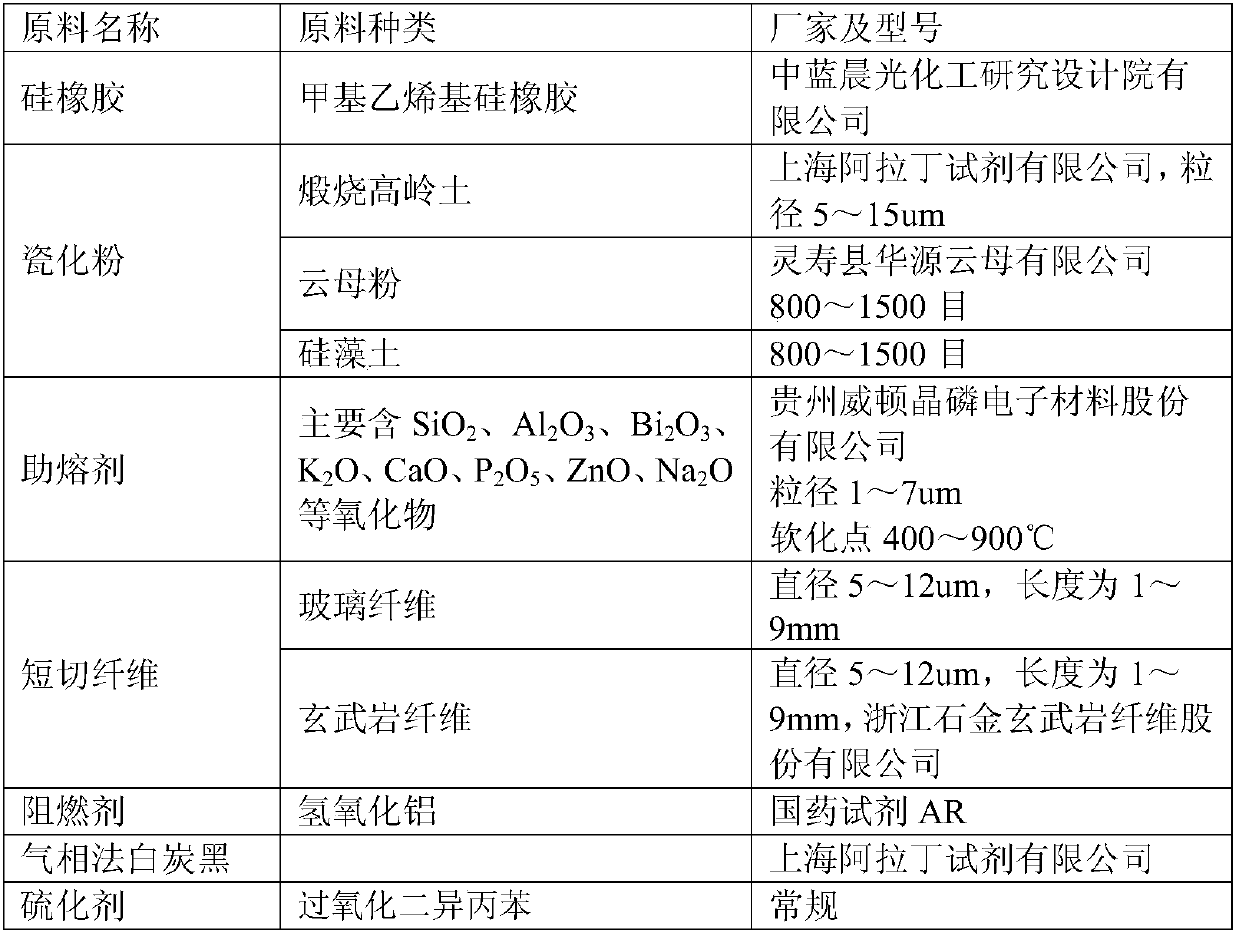

Method used

Image

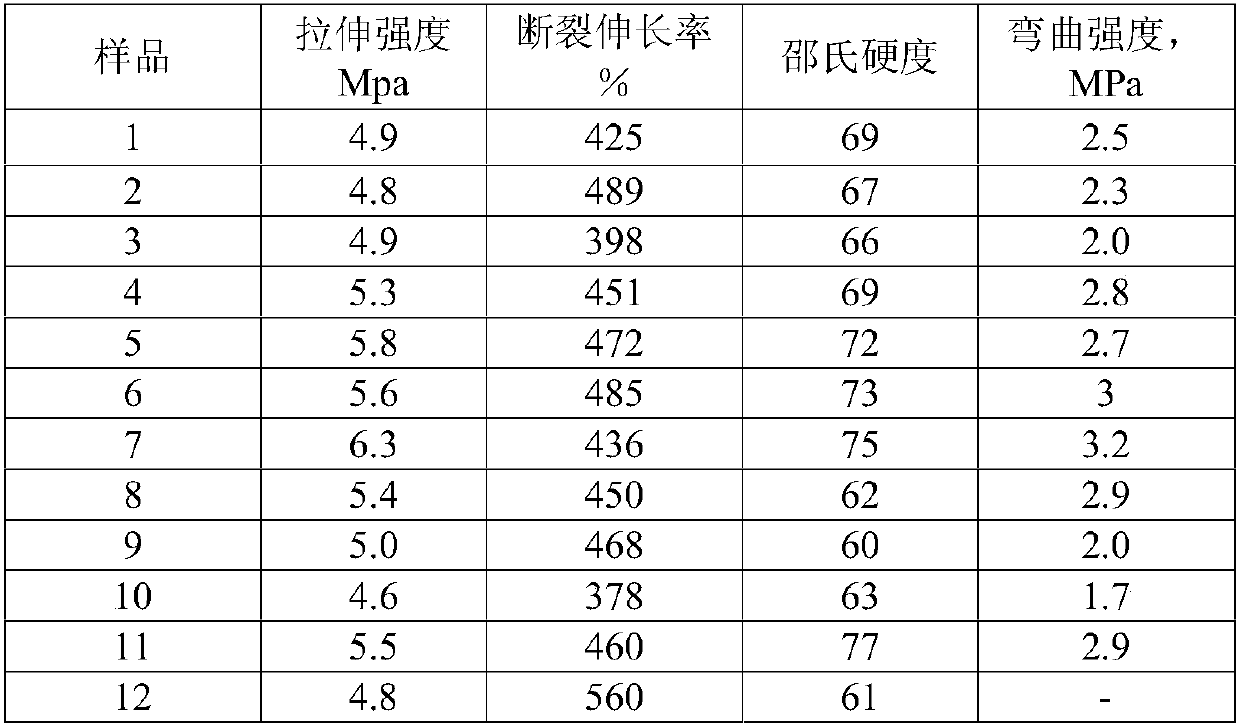

Examples

preparation example Construction

[0030] The method for preparing the flame-retardant silicone rubber from the above composition can adopt the methods commonly used in the art. Preferably, the following method is used for preparation:

[0031] The above composition is kneaded, thinned, and sheeted to obtain a porcelain silicone rubber composition; after the above porcelain silicone rubber composition is cooled at room temperature for 12 hours, it is vulcanized at 180°C and 10MPa for 45 minutes, and then Place it in an oven at 200°C for 4 hours to keep the desired flame-retardant silicone rubber composite material.

[0032] Another aspect of the present application also provides a flame-retardant silicone rubber, which is prepared by using the above-mentioned composition.

[0033] In the above-mentioned composition provided by the present application, under the action of the flux, the vitrified powder can be melted at a lower combustion temperature, and the silicon dioxide powder formed after the combustion of...

Embodiment 1

[0039] 100g silicone rubber, 25g porcelain powder (25g calcined kaolin), 50g flux, 25g chopped fiber (glass fiber), 30g flame retardant (Al(OH) 3 ), 20g of fumed white carbon black and 2g of vulcanizing agent (dicumyl peroxide) were added to the open mill and mixed evenly, thinly passed, and released into sheets to obtain a vitrified silicone rubber composition.

[0040] Cool the above porcelainable silicone rubber composition at room temperature for 12 hours, vulcanize it at 180°C and 10MPa for 45 minutes, and then place it in an oven at 200°C for 4 hours to obtain the required flame-retardant silicone rubber composite material .

[0041] The above flame-retardant silicone rubber composite material was divided into four samples, and ablated in a muffle furnace at 600°C, 800°C, 1000°C, and 1200°C for 20 minutes to obtain ablation products. A performance test was performed on the above-mentioned ablation products.

Embodiment 2

[0043] 100g silicone rubber, 50g porcelain powder (25g kaolin, 25 mica powder), 10g flux, 40g chopped fiber (glass fiber), 10g flame retardant (Al(OH) 3 ), 15g of fumed white carbon black and 2g of vulcanizing agent (double two five) were added to the open mill and mixed evenly, thinned, and sliced to obtain a porcelain silicone rubber composition.

[0044] Cool the above porcelainable silicone rubber composition at room temperature for 12 hours, vulcanize it at 180°C and 10MPa for 45 minutes, and then place it in an oven at 200°C for 4 hours to obtain the required flame-retardant silicone rubber composite material .

[0045] The above flame-retardant silicone rubber composite material was divided into four samples, and ablated in a muffle furnace at 600°C, 800°C, 1000°C, and 1200°C for 20 minutes to obtain ablation products. A performance test was performed on the above-mentioned ablation products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com