Transition metal phosphide porous carbon nanosheet composites and their preparation and application

A technology of composite materials and transition metals, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of limited price of platinum resources, low electronic conductivity, and few exposed active sites, and is suitable for large-scale production and preparation The effect of simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

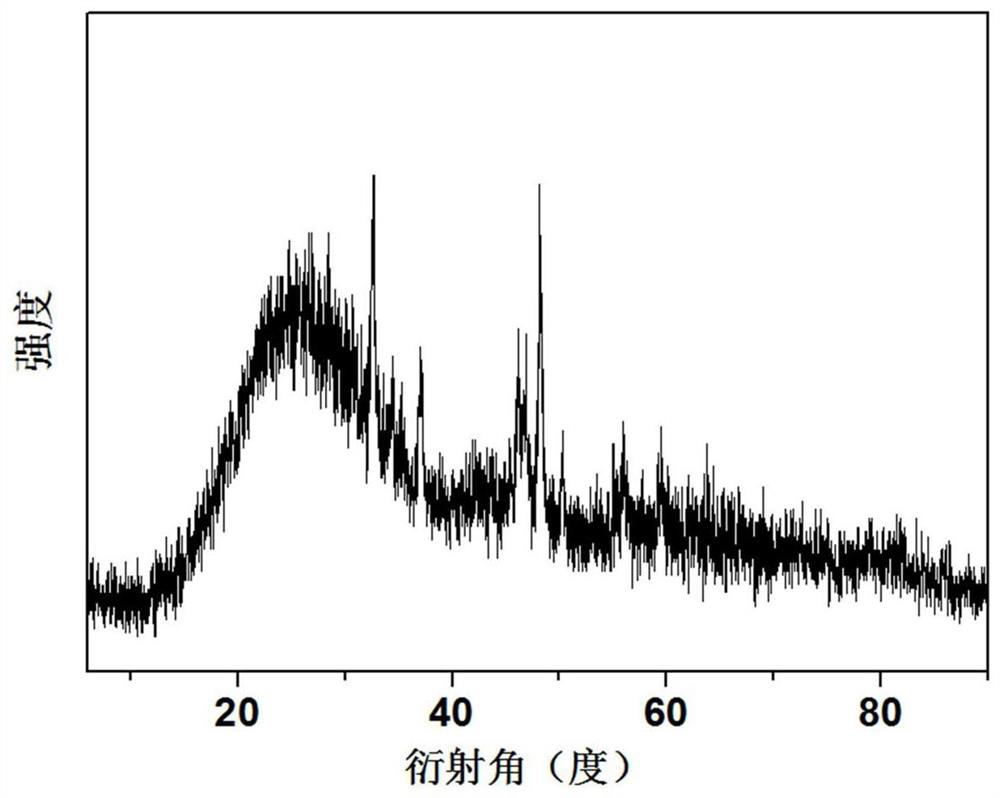

[0025] Weigh 6.8g of pentaerythritol into a flask, add 29.40g of phosphoric acid, stir to reduce pressure (vacuum degree is 0.1MPa), heat to 120°C, and keep warm for 1.5h to obtain light yellow transparent viscous pentaerythritol phosphate liquid. In another round bottom flask, add 120mL ethanol, 10mM ferric chloride and 16.38g melamine, fully stir for 1.5h, pour the pentaerythritol phosphate synthesized in the previous step into the melamine equipped with ethanol dispersant, heat to 80 ℃, stirred and refluxed for 6h, and rotary evaporated to obtain the precursor, put the precursor in a quartz boat, and in a nitrogen atmosphere, the temperature was raised to 350°C at a heating rate of 5°C / min, kept for 0.5h, and continued at a heating rate of 5°C / min Raise the temperature to 950°C, keep it for 2h, cool to room temperature and take it out. Such as figure 1 As shown by XRD, the obtained metal phosphide is FeP, and FeP is dispersed on the porous carbon nanosheet and covered by g...

Embodiment 2

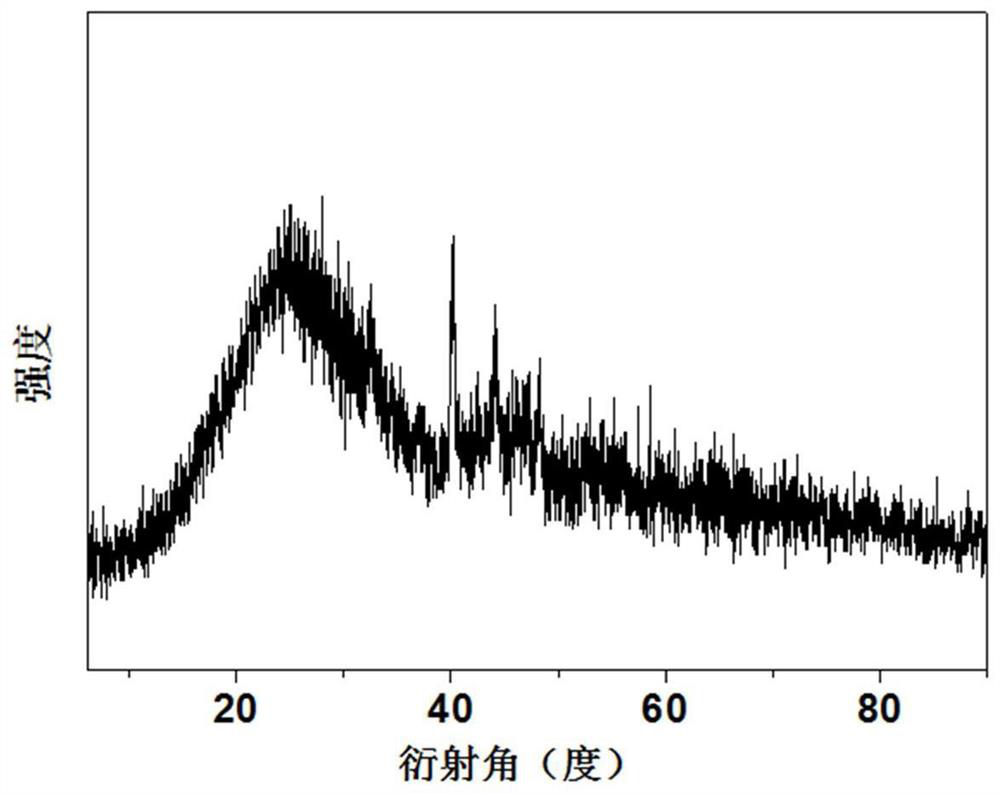

[0027] Weigh 6.8g of pentaerythritol into a flask, add 29.40g of phosphoric acid, stir to reduce pressure (vacuum degree is 0.1MPa), heat to 120°C, and keep warm for 1.5h to obtain light yellow transparent viscous pentaerythritol phosphate liquid. In another round bottom flask, add 120mL ethanol, 10mM ferric chloride and 16.38g melamine, fully stir for 1.5h, pour the pentaerythritol phosphate synthesized in the previous step into the melamine equipped with ethanol dispersant, heat to 80 ℃, stirred and refluxed for 6h, and rotary evaporated to obtain the precursor, put the precursor in a quartz boat, and in a nitrogen atmosphere, the temperature was raised to 350°C at a heating rate of 5°C / min, kept for 0.5h, and continued at a heating rate of 5°C / min Raise the temperature to 950°C, keep it for 4h, cool to room temperature and take it out. Such as figure 2 As shown by XRD, the obtained metal phosphide is Fe 2 P, Fe 2 P is dispersed on porous carbon nanosheets and covered by...

Embodiment 3

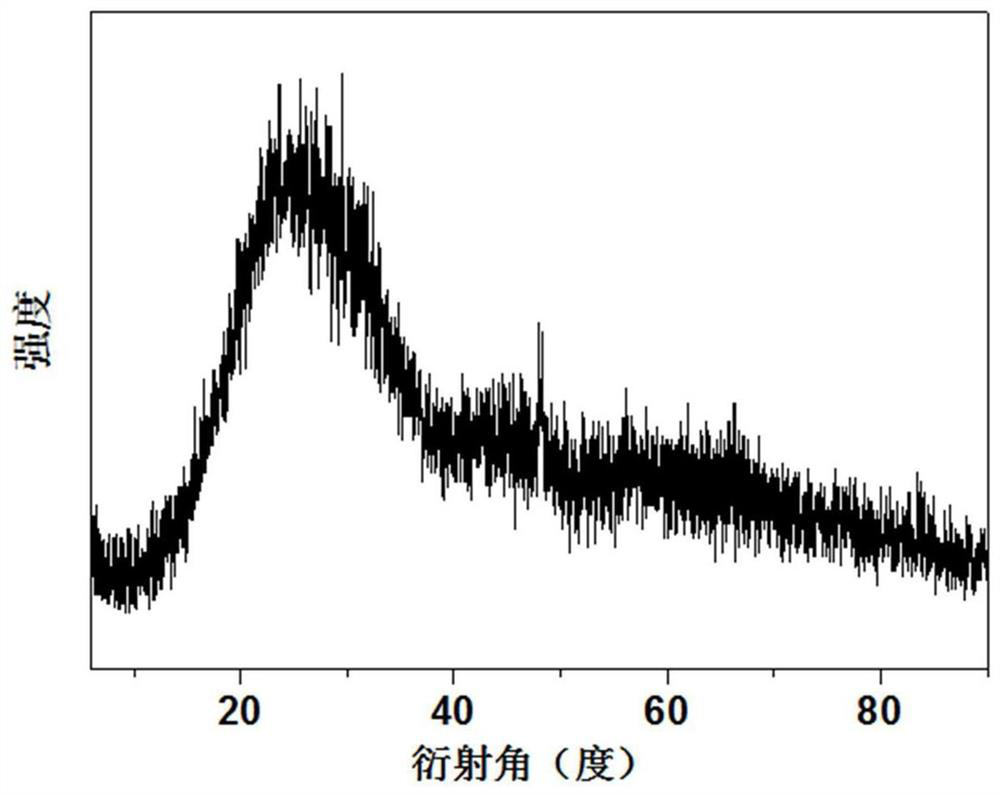

[0029] Weigh 6.8g of pentaerythritol into a flask, add 29.40g of phosphoric acid, stir to reduce pressure (vacuum degree is 0.1MPa), heat to 120°C, and keep warm for 1.5h to obtain light yellow transparent viscous pentaerythritol phosphate liquid. Add 120mL ethanol, 10mM cobalt chloride hexahydrate and 16.38g melamine in another round bottom flask, stir well for 1.5h, pour the pentaerythritol phosphate synthesized in the previous step into the melamine equipped with ethanol dispersant, and heat to 80°C, stirred and refluxed for 6h, and rotary evaporated to obtain the precursor, put the precursor in a quartz boat, and in a nitrogen atmosphere, raise the temperature to 350°C at a rate of 5°C / min, keep it for 0.5h, and continue to increase the temperature at 5°C / min The temperature was raised to 950°C, kept for 2h, cooled to room temperature and taken out. Such as image 3 As shown by XRD, the obtained metal phosphide is CoP, and CoP is dispersed on the porous carbon nanosheets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com