Non-aqueous lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in non-aqueous electrolytes, batteries, secondary batteries, etc., can solve the problems of decreased conductivity, affecting the electrochemical performance of batteries, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

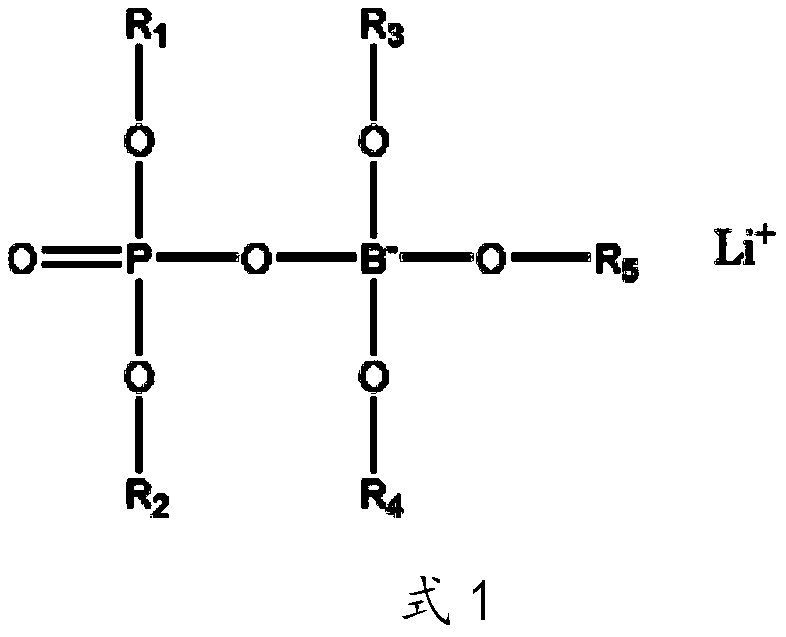

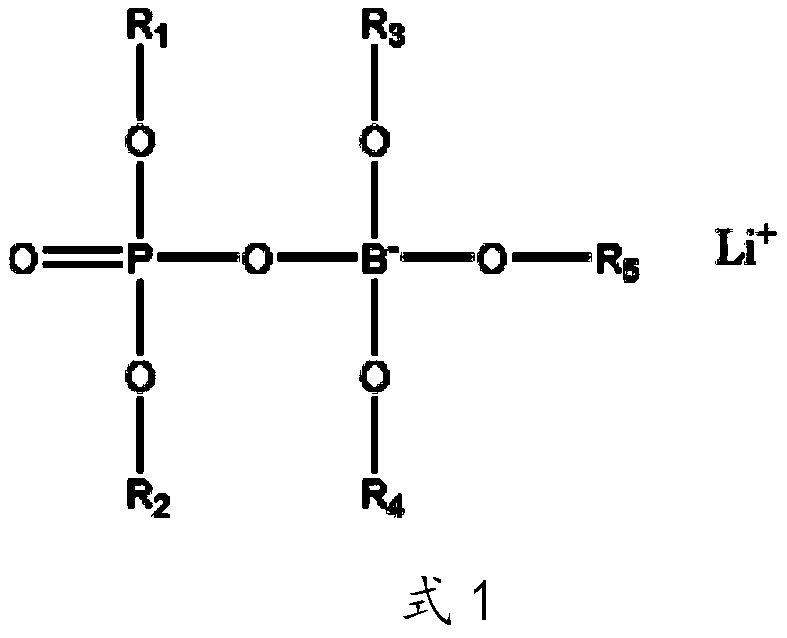

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare electrolytic solution in the vacuum drying glove box of moisture content6 The lithium salt concentration is 0.6mol / L, the content of 1,3-propane sultone is 4% of the total weight of the electrolyte, the content of fluoroethylene carbonate is 6% of the total weight of the electrolyte, and the content of adiponitrile The content is 5% of the total weight of the electrolyte, the content of biphenyl is 4% of the total weight of the electrolyte, and the flame retardant additive A is 5% of the total weight of the electrolyte.

Embodiment 2

[0024] Embodiment 2: prepare electrolytic solution in the vacuum drying glove box of moisture content6 The lithium salt concentration is 0.7mol / L, the content of 1,3-propane sultone is 4% of the total weight of the electrolyte, the content of fluoroethylene carbonate is 6% of the total weight of the electrolyte, and the content of adiponitrile The content is 5% of the total weight of the electrolyte, the content of biphenyl is 4% of the total weight of the electrolyte, and the flame retardant additive A is 5% of the total weight of the electrolyte.

Embodiment 3

[0026] Embodiment 3: prepare electrolytic solution in the vacuum drying glove box of moisture content6 The lithium salt concentration is 0.8mol / L, the content of 1,3-propane sultone is 4% of the total weight of the electrolyte, the content of fluoroethylene carbonate is 6% of the total weight of the electrolyte, and the content of adiponitrile The content is 5% of the total weight of the electrolyte, the content of biphenyl is 4% of the total weight of the electrolyte, and the flame retardant additive A is 5% of the total weight of the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com