Preparation method of milk-flavor frozen rice sugar

A frozen rice sugar and milk-flavored technology, which is applied in confectionery, confectionery industry, and sugar-containing food ingredients, etc., can solve the problems of excessive maltose, sticking to the teeth, and single taste, and achieve natural and three-dimensional milk flavor Full-bodied, creamy soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

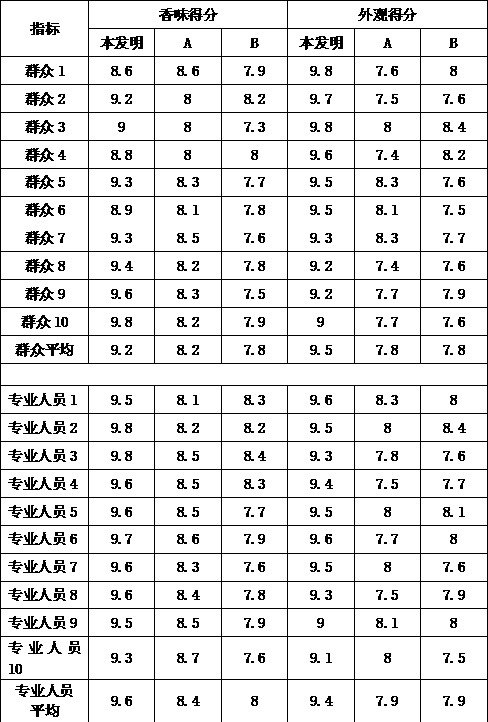

Examples

Embodiment 1

[0037] The preparation method of a kind of milk flavor frozen rice candy that the present invention proposes, processing production process is as follows:

[0038] The first step: prepare milk-flavored compound seasoning powder, and its preparation method is made up of following several steps:

[0039] 1. Material pretreatment: Stir 4 parts of modified starch, 40 parts of water, and 18 parts of maltodextrin evenly. The method of adding is to slowly add the modified starch into the water, then slowly add the maltodextrin into the water, and stir well; Then add 4 parts of the original yeast extract, stir well to get the mixed material 1;

[0040] 2. Chemical material treatment: heat up and dissolve 18 parts of seabuckthorn fruit oil and 0.6 part of leek flower oil in the oil phase pot, add 55 parts of fructose syrup into the syrup pot, mix material 1, soybean protein isolate 8 3.5 parts of sodium caseinate, 1 part of monoglyceride, and 10 parts of water are added to the water p...

Embodiment 2

[0056] Modified starch is modified starch obtained by denaturing lotus root starch through acetate denaturation. In the first step, 18 parts of seabuckthorn fruit oil and 0.6 parts of chive flower oil are heated and dissolved in the oil phase pot, and the temperature is controlled at 75°C; and 55 parts of fructose syrup are added into the syrup pot, and the temperature is raised to 55°C . In the first step, super ice temperature flavor compounding: put the mixed material 2 mixed in step 3 into the super ice temperature flavor compounding tank, control the temperature in the tank to minus 2 degrees to 0 degrees, turn on the stirring device, and the stirring speed is 35 RPM and stir for 15 minutes to complete the flavor compounding work. The second step is to choose glutinous rice with full grains and white body length, put it on bamboo radish, wash it in a clear water pool, and then pour it into a clear water pool to soak for 14-15 hours, then remove it to a bamboo basket and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com