Nano particle@graphene/polyether-ether-ketone composite material and preparation method and application thereof

A polyetheretherketone, composite material technology, applied in medical science, tissue regeneration, prosthesis and other directions, can solve problems such as failure and osteolysis, short service life, wear and tear, and achieve good biocompatibility and improved service life. , The effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

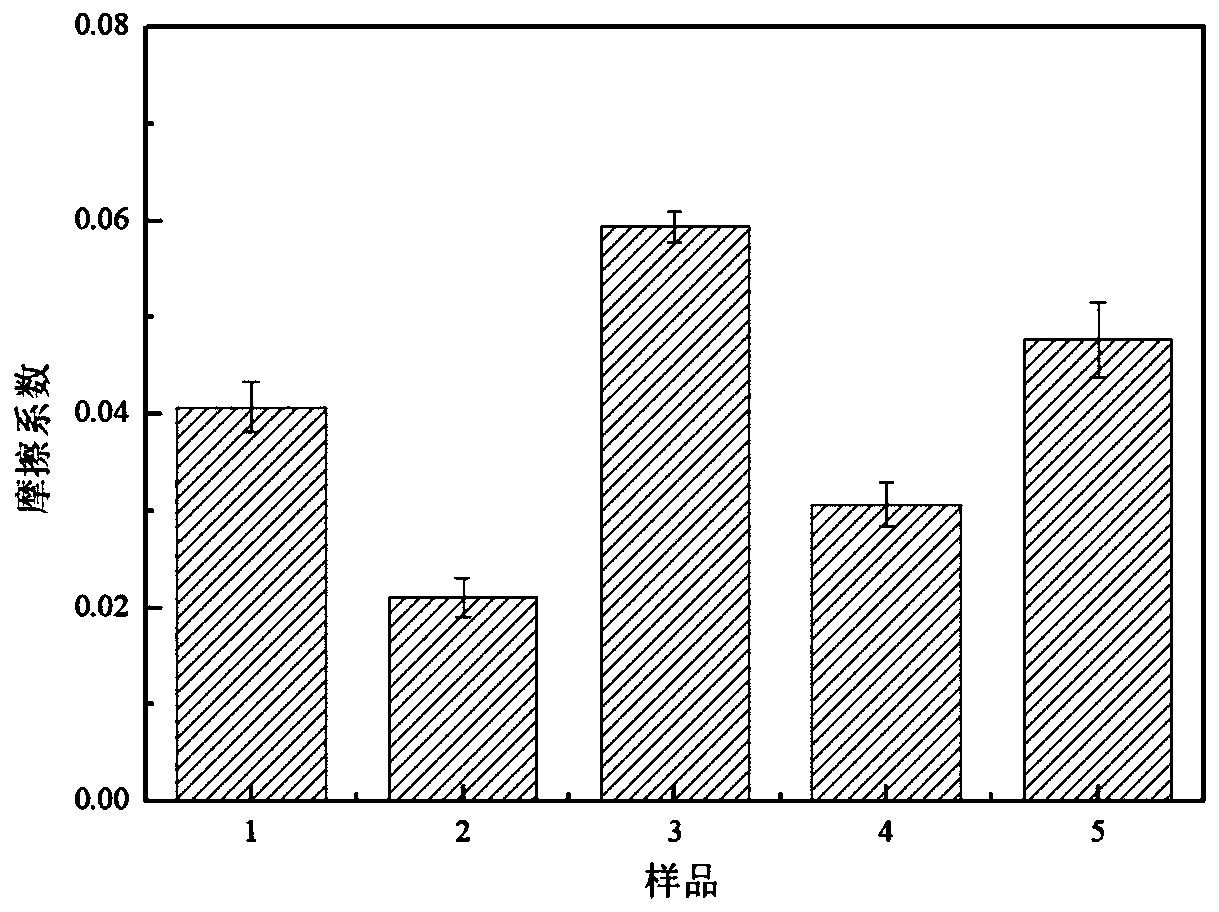

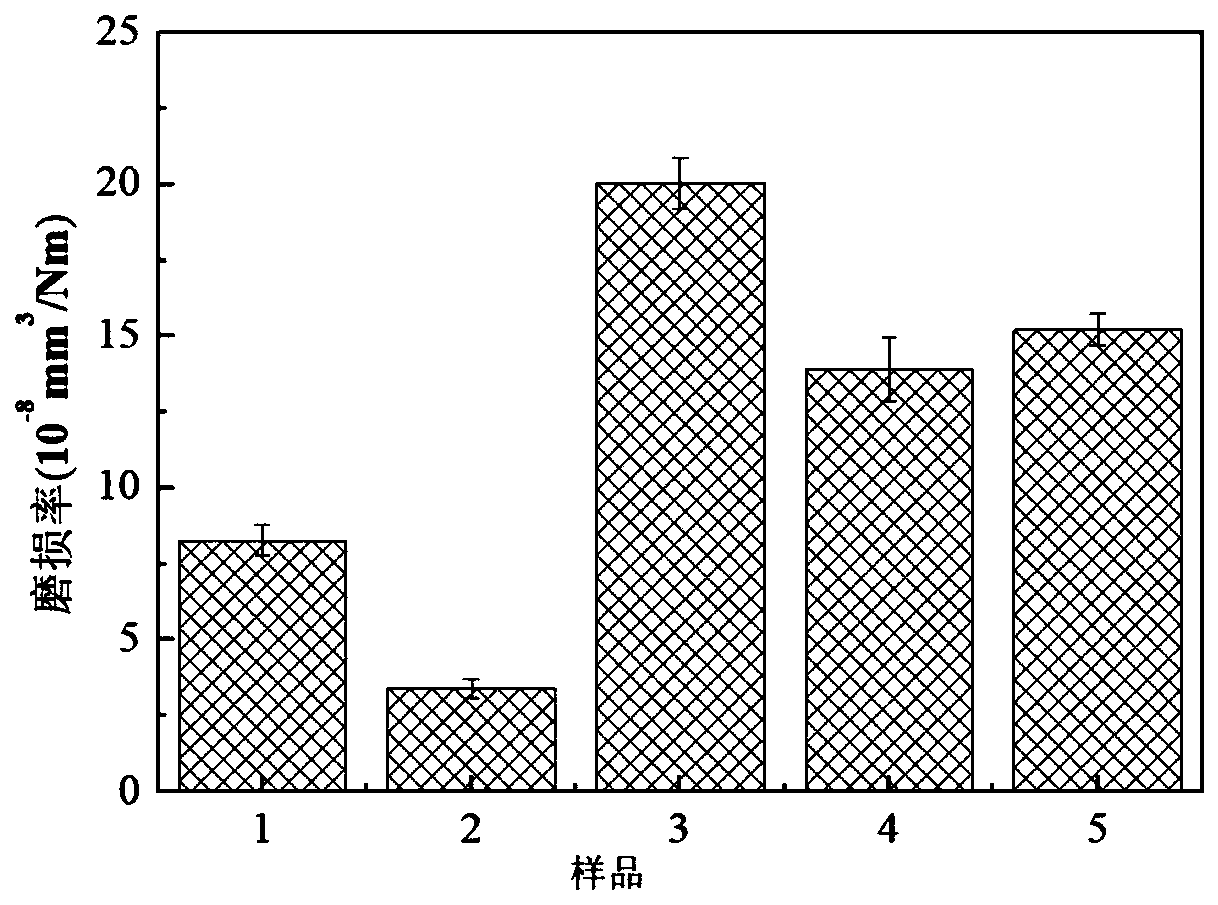

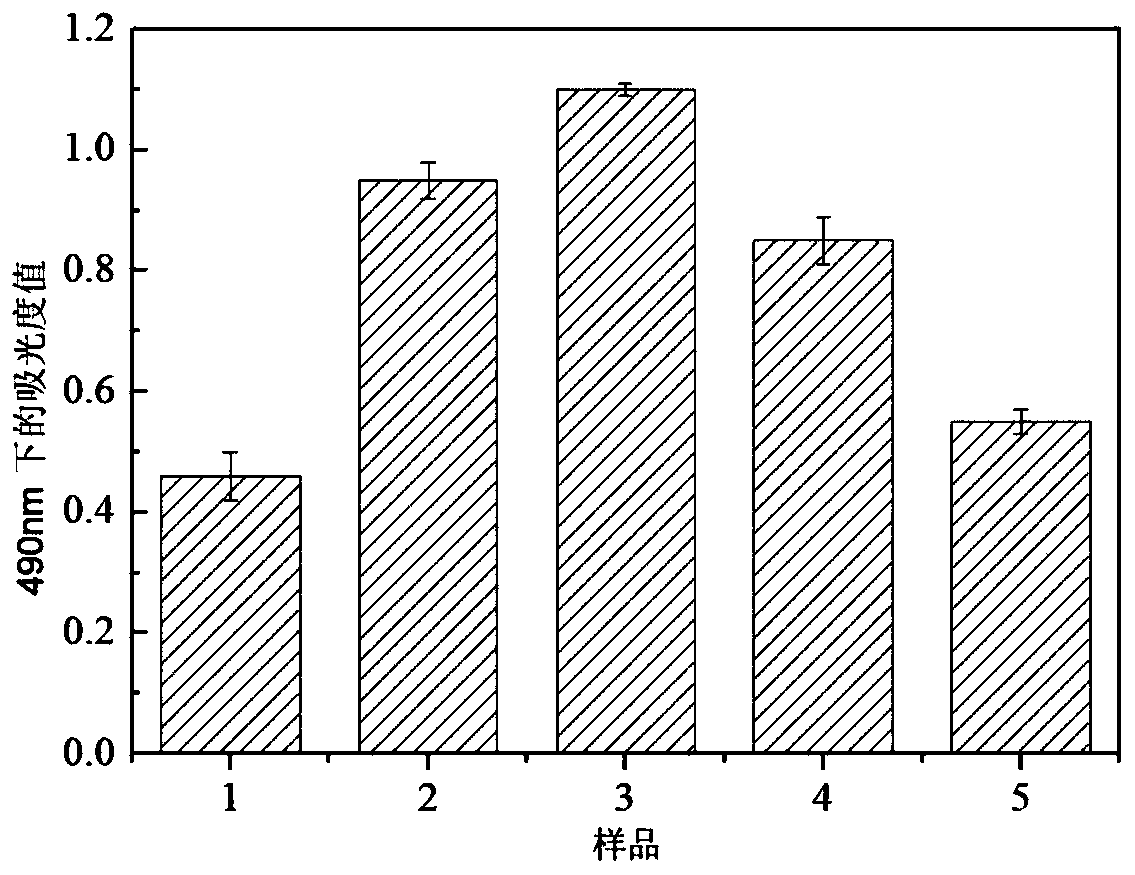

Embodiment 1

[0052] The volume percentage of each raw material for preparing nanoparticle@graphene / polyether ether ketone composite material is as follows: polyether ether ketone 78%, carbon fiber 15%, graphene 1%, nano-zirconia 5%, nano-hydroxyapatite 1% .

[0053] The method of preparing nanoparticle@graphene / polyether ether ketone composite material is as follows:

[0054] Step1: Preparation of nanoparticles@graphene hybrid materials

[0055] Prepare nanoparticle@graphene hybrid materials by chemical bonding, specifically use nano-zirconia, nano-hydroxyapatite and graphene as raw materials, and prepare ZrO by chemical bonding 2 @GO hybrid material and HA@GO hybrid material, the specific operation is as follows:

[0056] (1) Preparation of ZrO 2 @GO hybrid materials

[0057] Firstly, immerse nano zirconia in dilute acid—hydrochloric acid with a volume concentration of 5% for 5 minutes. The purpose of this treatment is to activate the hydroxyl groups on the surface of nano zirconia. ...

Embodiment 2

[0071] The volume percentage of each raw material for preparing nanoparticle@graphene / polyether ether ketone composite material is as follows: polyether ether ketone 70%, carbon fiber 20%, graphene 2%, nano-zirconia 5%, nano-hydroxyapatite 3% .

[0072] The method of preparing nanoparticle@graphene / polyether ether ketone composite material is as follows:

[0073] Step1: Preparation of nanoparticles@graphene hybrid materials

[0074] Using nano-zirconia, nano-hydroxyapatite and graphene as raw materials, adopt the same operation as in Example 1 (note: the volume percentage of nano-zirconia, nano-hydroxyapatite and graphene is different from that of Example 1) to prepare ZrO 2 @GO hybrid materials and HA@GO hybrid materials.

[0075] Step2: Mixing

[0076] PEEK, carbon fiber, ZrO 2 The @GO hybrid material and the HA@GO hybrid material were fully mixed with a high-speed mixer.

[0077] Step3: hot pressing sintering molding

[0078] Pour the mixed molding material into the ...

Embodiment 3

[0080] The volume percentage of each raw material for preparing nanoparticle@graphene / polyether ether ketone composite material is as follows: polyether ether ketone 67%, carbon fiber 20%, graphene 3%, nano-zirconia 5%, nano-hydroxyapatite 5% .

[0081] The method of preparing nanoparticle@graphene / polyether ether ketone composite material is as follows:

[0082] Step1: Preparation of nanoparticles@graphene hybrid materials

[0083] Using nano-zirconia, nano-hydroxyapatite and graphene as raw materials, adopt the same operation as in Example 1 (note: the volume percentage of nano-zirconia, nano-hydroxyapatite and graphene is different from that of Example 1) to prepare ZrO 2 @GO hybrid materials and HA@GO hybrid materials.

[0084] Step2: Mixing

[0085] PEEK, carbon fiber, ZrO 2 The @GO hybrid material and the HA@GO hybrid material were fully mixed with a high-speed mixer.

[0086] Step3: hot pressing sintering molding

[0087] Pour the mixed molding material into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com