Preparation method of 3-(N,N-diallyl)amino-4-methoxy acetanilide

A technology of methoxyacetanilide and diallyl is applied in the field of continuous preparation of 3-amino-4-methoxyacetanilide by using a microreactor, which can solve the problems of long reaction time and low production efficiency, and achieves the The effect of shortening reaction time, improving production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

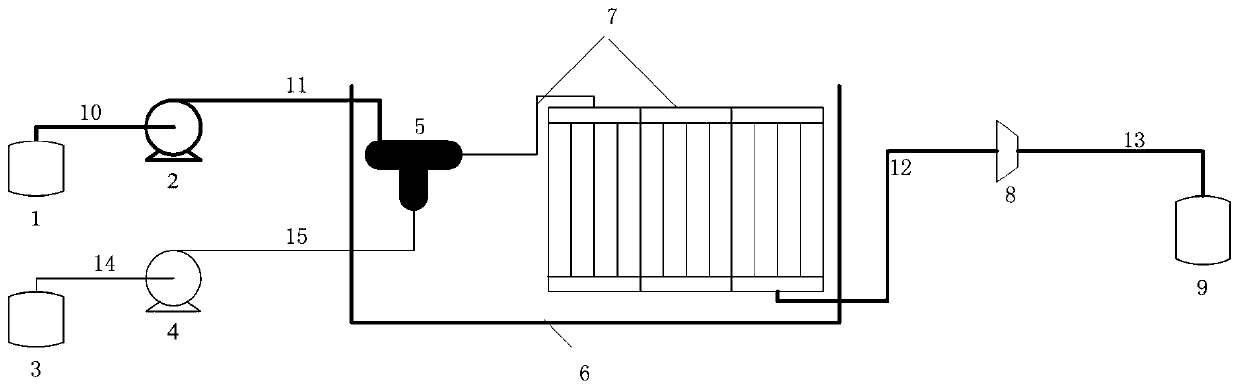

[0041] Please refer to figure 1, the invention provides a reaction device for preparing 3-(N,N-diallyl)amino-4-methoxyacetanilide, comprising two feed tanks (1 is feed tank A, and the material contained in it is A includes 2-amino-4-acetamidoanisole, acid-binding agent and water, 3 is feed tank B, the material B in it includes allyl chloride), high-temperature pump A (2), pump B (4), T Type mixer (5), oil bath (6), spiral tubular microreactor (7, 316L stainless steel material with an inner diameter of 0.5mm), back pressure valve (8), discharge tank (9), 4 with Insulated pipelines (10-13), 2 uninsulated pipelines (14 and 15). The feed tank A (1) is connected to the high-temperature pump A (2) through a pipeline (10) with insulation, and the high-temperature pump A (2) is connected to the T-type mixer (5) through a pipeline (11) with insulation; Tank B (3) is connected to pump B (4) through pipeline (14), and pump B (4) is connected to T-type mixer (5) through pipeline (15); t...

Embodiment 2

[0043] Reactor see figure 1 , Mix 2-amino-4-acetamidoanisole, water, and sodium acetate at a mass ratio of 1:19:1.9, heat up to 90°C as material A; chloropropene as material B. Material A and material B are continuously entered into the helical tubular microreactor (7, the inner diameter of the pipe is 0.5mm) through the T-type mixer (5) at 1.46g / min and 0.11g / min speed respectively, and passed through the oil bath (6 ) to control the reaction temperature to 120°C, the back pressure valve (8) to control the reaction pressure to 1.0Mpa, and the reaction residence time to be 12min. The product of 4-methoxyacetanilide has a purity of 89.81% and a yield of 94.1%.

Embodiment 3

[0045] Reactor see figure 1 , mix 2-amino-4-acetamidoanisole, water, sodium acetate and dimethylacetamide at a mass ratio of 1:8:1.7:1, heat up to 90°C as material A; mix allyl chloride and ethanol with Mass ratio 1:2.3 mixed, as material B. Material A and material B are continuously entered into the helical tubular microreactor (7, the inner diameter of the pipe is 0.5mm) through the T-type mixer (5) at 0.52g / min and 0.28g / min speed respectively, and passed through the oil bath (6 ) to control the reaction temperature to 120°C, the back pressure valve (8) to control the reaction pressure to 1.0Mpa, and the reaction residence time to be 10min. - Methoxyacetanilide product, purity 91.81%, yield 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com