A kind of high-solid anionic aqueous polyurethane emulsion and preparation method thereof

A water-based polyurethane and anion technology, which is applied in the field of high-solid anion water-based polyurethane emulsion and its preparation, can solve the problems that the water resistance of the film of the material cannot meet the requirements, and achieve the avoidance of high viscosity, good compatibility, and simplified application process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

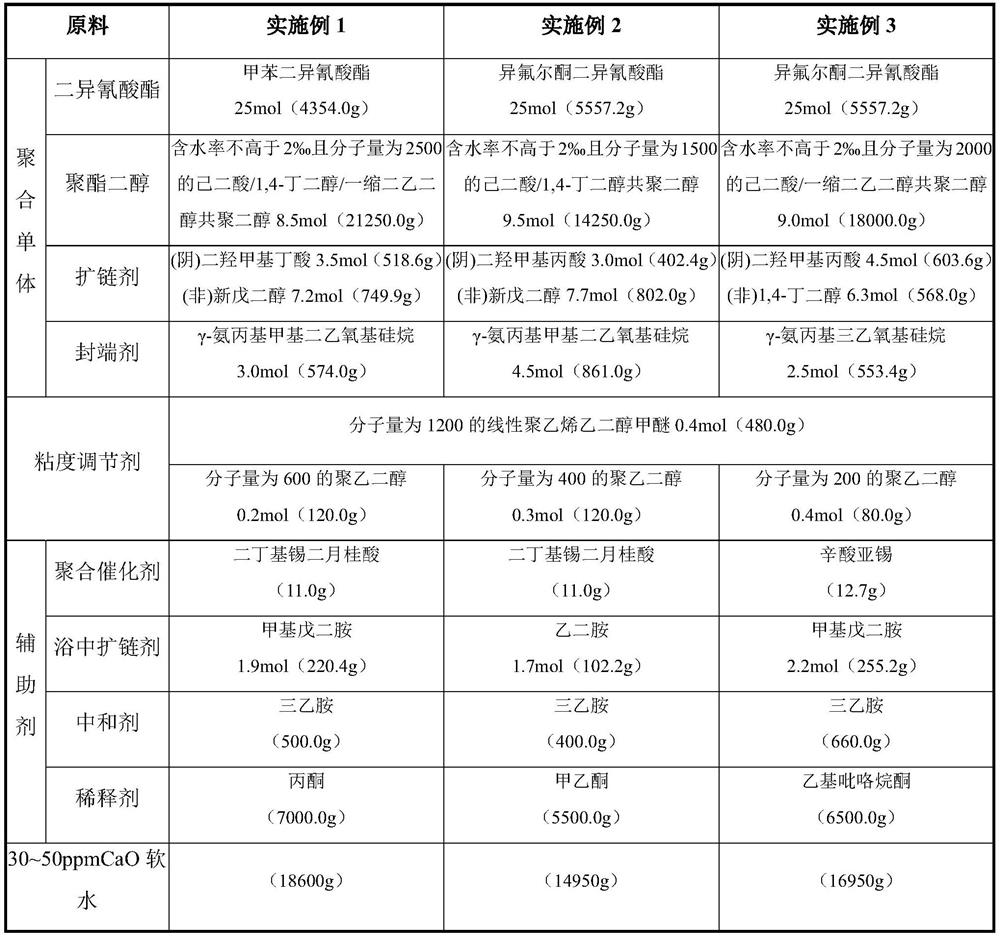

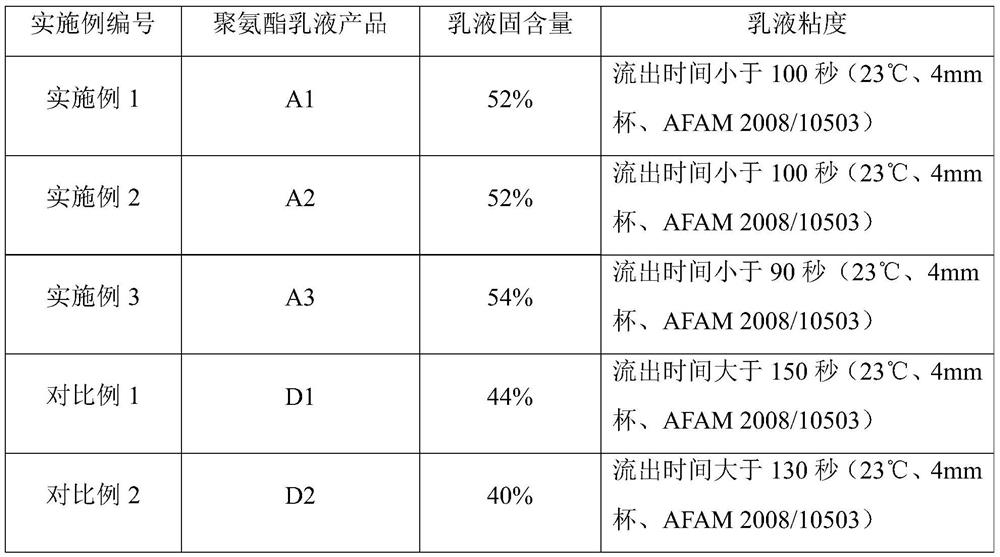

Examples

preparation example Construction

[0068]The preparation method of the high solid content anionic waterborne polyurethane emulsion of the present invention includes the following steps:

[0069](1) Prepolymerization: prepolymerize polyester diol, diisocyanate, and polymerization catalyst to prepare high solid content anionic waterborne polyurethane prepolymer;

[0070](2) Chain extension: the high solids anionic waterborne polyurethane prepolymer is reacted with a chain extender, a viscosity modifier, and a part of a diluent to prepare a high solids anionic waterborne polyurethane intermediate, wherein the chain extender Including non-ionic chain extenders and anionic chain extenders;

[0071](3) End-capping: reacting the high-solid-content anionic waterborne polyurethane intermediate with a blocking agent to prepare a high-solid-content anionic waterborne polyurethane polymer;

[0072](4) Emulsification: mixing and emulsifying the high solids anionic waterborne polyurethane polymer, neutralizer, remaining diluent, bath chain ex...

Embodiment 1

[0116](1) Pre-polymerization

[0117](1.1) Put the polyester diol into the reactor and raise the temperature to 70°C;

[0118](1.2) Put in diisocyanate and maintain stirring, control the temperature of the reaction system to 80°C, and maintain stirring for 20 minutes;

[0119](1.3) Maintain the temperature of the reaction system at 80°C, and put in the polymerization catalyst at a constant speed within 20 minutes;

[0120](1.4) Increase the temperature and control the temperature of the reaction system to 85° C., and keep the temperature for 90 minutes to prepare a high-solid anionic waterborne polyurethane prepolymer.

[0121](2) Chain extension

[0122](2.1) Cool down the reaction system of step (1.4) to 75°C;

[0123](2.2) Add viscosity modifier and anionic chain extender uniformly within 15 minutes, and maintain the reaction temperature at 75°C;

[0124](2.3) Control the reaction temperature to 80°C and continue to stir the reaction for 20 minutes, then lower the temperature to 77°C and continue to sti...

Embodiment 2

[0138](1) Pre-polymerization

[0139](1.1) Put the polyester diol into the reactor and raise the temperature to 75°C;

[0140](1.2) Put in diisocyanate and maintain stirring, control the temperature of the reaction system to 80°C, and maintain stirring for 25min;

[0141](1.3) Maintain the temperature of the reaction system at 80°C, and put in the polymerization catalyst at a constant speed within 15 minutes;

[0142](1.4) Increase the temperature and control the temperature of the reaction system to 85° C., and keep the temperature for 90 minutes to prepare a high-solid anionic waterborne polyurethane prepolymer.

[0143](2) Chain extension

[0144](2.1) Cool down the reaction system of step (1.4) to 80°C;

[0145](2.2) Add viscosity modifier and anionic chain extender uniformly within 15 minutes, and maintain the reaction temperature at 80°C;

[0146](2.3) Control the reaction temperature to 85°C and continue to stir the reaction for 30 minutes, then lower the temperature to 80°C and continue to stir the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com