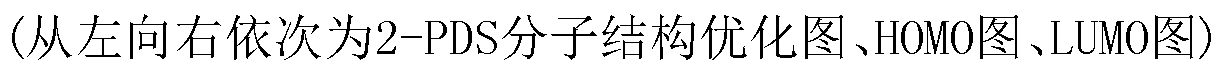

New purpose of 2,2'- dithiopyridine, electroplating hole filling additive with same and electroplating method adopting additive

A dithiodipyridine, electroplating and hole filling technology, applied in the field of compounds, can solve the problems of low final yield, high investment cost, environmental pollution, etc., achieve strong conductivity and reliability, smooth and dense surface, shorten the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of Test Plates

[0046] Cutting→drilling→cleaning→immersion copper (taking a through-hole plate with a depth-to-diameter ratio of 1.2:1 as an example):

[0047] 2. Specific steps of through-hole plating and filling process:

[0048] (1) Preparation of electroplating solution

[0049] formula:

[0050]

[0051] Preparation method

[0052] Step 1: Weigh copper sulfate in a beaker;

[0053] Step 2: Add deionized water and stir to dissolve;

[0054] Step 3: Measure sulfuric acid and slowly inject it into the copper sulfate solution, stirring and diluting until completely dissolved;

[0055] Step 4: adding chloride ion, accelerator, inhibitor respectively in the dissolved copper sulfate solution;

[0056] Step 5: Add the new leveling agent, stir until the solution is evenly mixed, and cool to room temperature for use.

[0057] (2) Sample pre-treatment: degreasing→water washing→acid leaching

[0058] Degreasing: Since the test board will inevitably h...

Embodiment 2

[0065] 1. Preparation of test board:

[0066] Cutting → Drilling → Cleaning → Immersion Copper (Taking a through-hole plate with a depth-to-diameter ratio of 1.2:1 as an example)

[0067] 2. Specific steps of through-hole plating and filling process:

[0068] (1) Preparation of electroplating solution

[0069] formula:

[0070]

[0071]

[0072] Preparation method is identical with embodiment 1.

[0073] (2) Sample pre-treatment: degreasing→water washing→acid leaching

[0074] Degreasing: Since the test board will inevitably have grease, finger prints and other dirt on the surface during the preparation process, in order to make the pretreatment effect better, degreasing is required to remove organic pollutants on the copper surface, and the degreasing temperature is controlled at 45±5 ℃, the degreasing time is 2-3min;

[0075] Water washing: first wash with a large amount of tap water to ensure that the insoluble substances in the degreasing liquid are washed away,...

Embodiment 3

[0081] 1. Preparation of test board:

[0082] Cutting → Drilling → Cleaning → Immersion Copper (Taking a through-hole plate with a depth-to-diameter ratio of 1.2:1 as an example)

[0083] 2. Specific steps of through-hole plating and filling process:

[0084] (1) Preparation of electroplating solution

[0085] formula:

[0086]

[0087] Preparation method is identical with embodiment 1.

[0088] (2) Sample pre-treatment: degreasing→water washing→acid leaching

[0089] Degreasing: Since the test board will inevitably have grease, finger prints and other dirt on the surface during the preparation process, in order to make the pretreatment effect better, degreasing is required to remove organic pollutants on the copper surface, and the degreasing temperature is controlled at 45±5 ℃, the degreasing time is 2-3min;

[0090] Water washing: first wash with a large amount of tap water to ensure that the insoluble substances in the degreasing liquid are washed away, and then wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com