Quick-dry moisture-absorption knitted fabric and preparation method thereof

A knitted fabric, moisture absorption and quick-drying technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of moisture absorption and quick-drying effect to be improved, slow longitudinal diffusion, color difference between inner and outer layers, etc., to achieve good moisture absorption and quick-drying effect, good wash fastness, low water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] In a specific embodiment of the present invention, a method for preparing a moisture-absorbing quick-drying knitted fabric is provided, and the method for preparing the moisture-absorbing knitted fabric comprises the following steps:

[0050] Weft knitting the Siro composite yarn to obtain a knitted fabric;

[0051] Finish the knitted fabric to obtain a moisture-absorbing and quick-drying knitted fabric;

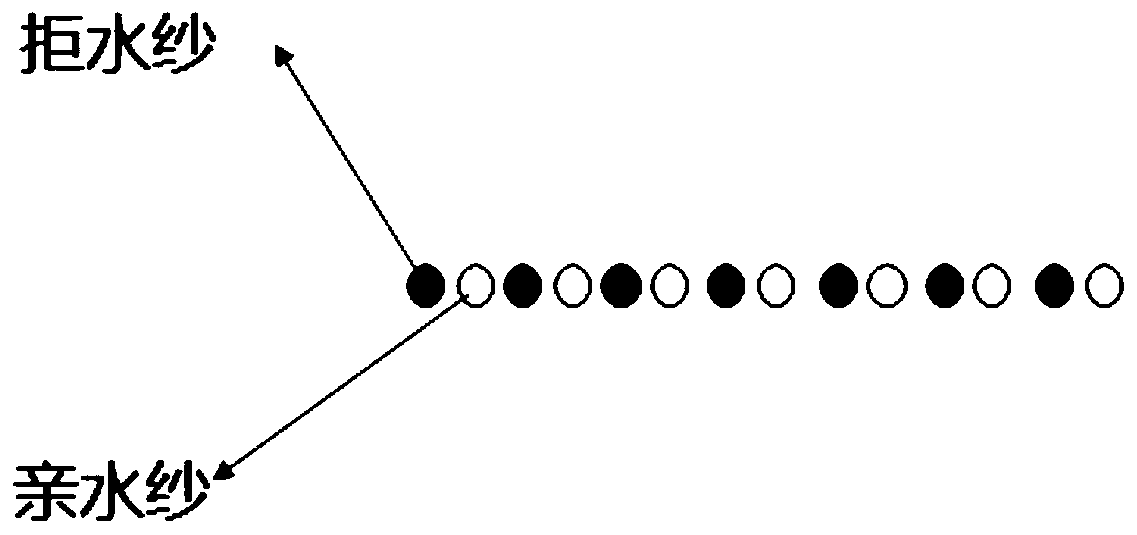

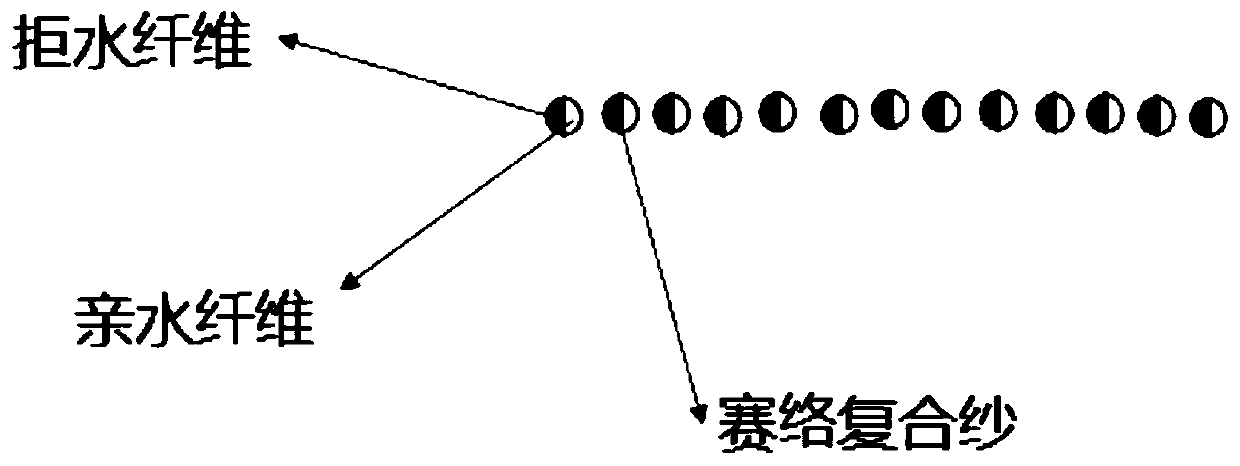

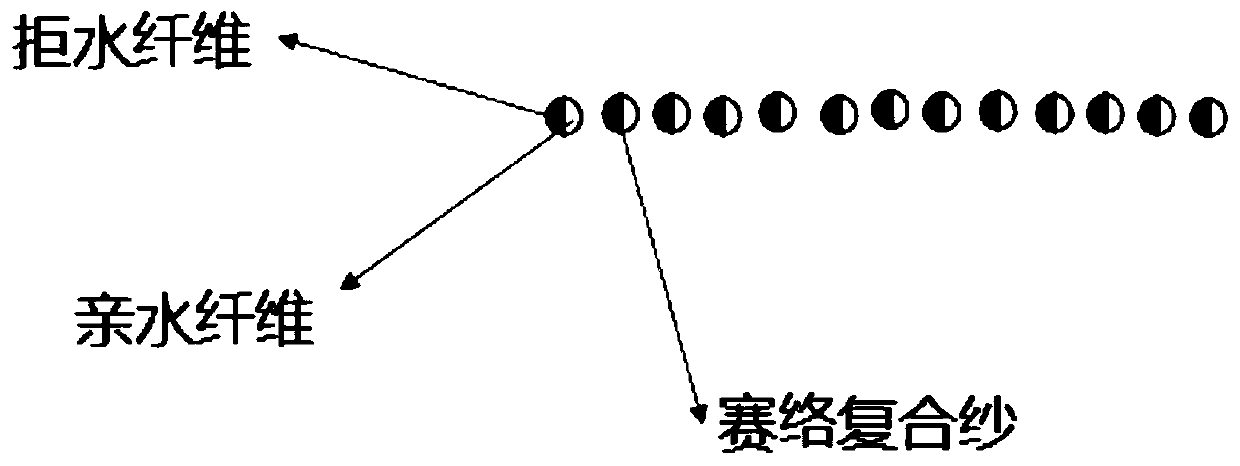

[0052] Among them, the Siro composite yarn is obtained by spinning the hydrophilic fiber and the water-repellent fiber separately into roving, and then blending the hydrophilic roving and the water-repellent roving.

[0053] In the fabric obtained through the above steps, the hydrophilic points and water-repellent points can be evenly distributed, so that sweat can be absorbed by the fabric and evaporated quickly. At the same time, the siro composite yarn reduces the moisture absorption rate of the fabric, thereby improving the drying speed of the fabric after absorb...

Embodiment 1

[0098] This embodiment provides a kind of 30s / l pure cotton moisture-absorbing quick-drying plain weave cloth (160g / m 2 ), which is prepared by the following steps:

[0099] Step 1: Preparation of 30s / 1 siro composite yarn:

[0100] Cotton (cotton 1) scouring→bleaching→dyeing→soaping, color fixing→hydrophilic soft oil→drying

[0101] Cotton (cotton 2) scouring→bleaching→dyeing→soaping, color fixing→over fluorine-containing water repellent→drying

[0102] The above-mentioned cotton 1 and cotton 2 are blended into 30S single yarn through a siro spinning frame.

[0103] Wherein cotton 1, the scouring of cotton fiber, bleaching, dyeing, soaping, color fixation all carry out according to conventional cotton dyeing process, after the color fixation is finished, cotton is added concentration and is 20g / L hydrophilic soft oil A-100 (Delong Company) in the aqueous solution, 45 ℃ for 25 minutes, the bath ratio is 1:10. The treated yarn is dried by high frequency at 85°C.

[0104] T...

Embodiment 2

[0111] This example provides a 20s / 1 pure cotton moisture-absorbing and quick-drying piqué, which is prepared through the following steps:

[0112] Step 1: Preparation of 20s / 1 siro composite yarn:

[0113] Cotton (cotton 1) scouring→bleaching→dyeing→soaping, color fixing→hydrophilic soft oil→drying

[0114] Cotton (cotton 2) scouring→bleaching→dyeing→soaping, color fixing→passing fluorine-free water repellent→drying

[0115] The above-mentioned cotton 1 and cotton 2 are blended into 20s / 1 single yarn through a siro spinning frame.

[0116] Among them, the scouring, bleaching, dyeing, soaping, and color fixing of cotton 1 are all carried out according to the conventional cotton dyeing process. After the color fixing is completed, the cotton is added with a concentration of 20g / L hydrophilic soft oil S-3171 (Dyeing Online Company ) in an aqueous solution at 40°C for 20 minutes with a bath ratio of 1:15. The treated yarn is dried by high frequency at 85°C.

[0117] Cotton 2’...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com