Method for preparing glue-free self-bonding environment-friendly artificial board through microwave pretreatment of wood flour

An environmentally friendly wood-based panel and wood-based panel technology, applied in radiation/wave wood treatment, wood treatment, manufacturing tools, etc., can solve the loss of skeleton tensile performance and static bending strength, difficulty in the performance budget of wood-based panels, and poor environment and human body. Influence and other issues, to ensure the overall pressing effect, enhance the overall strength, low water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

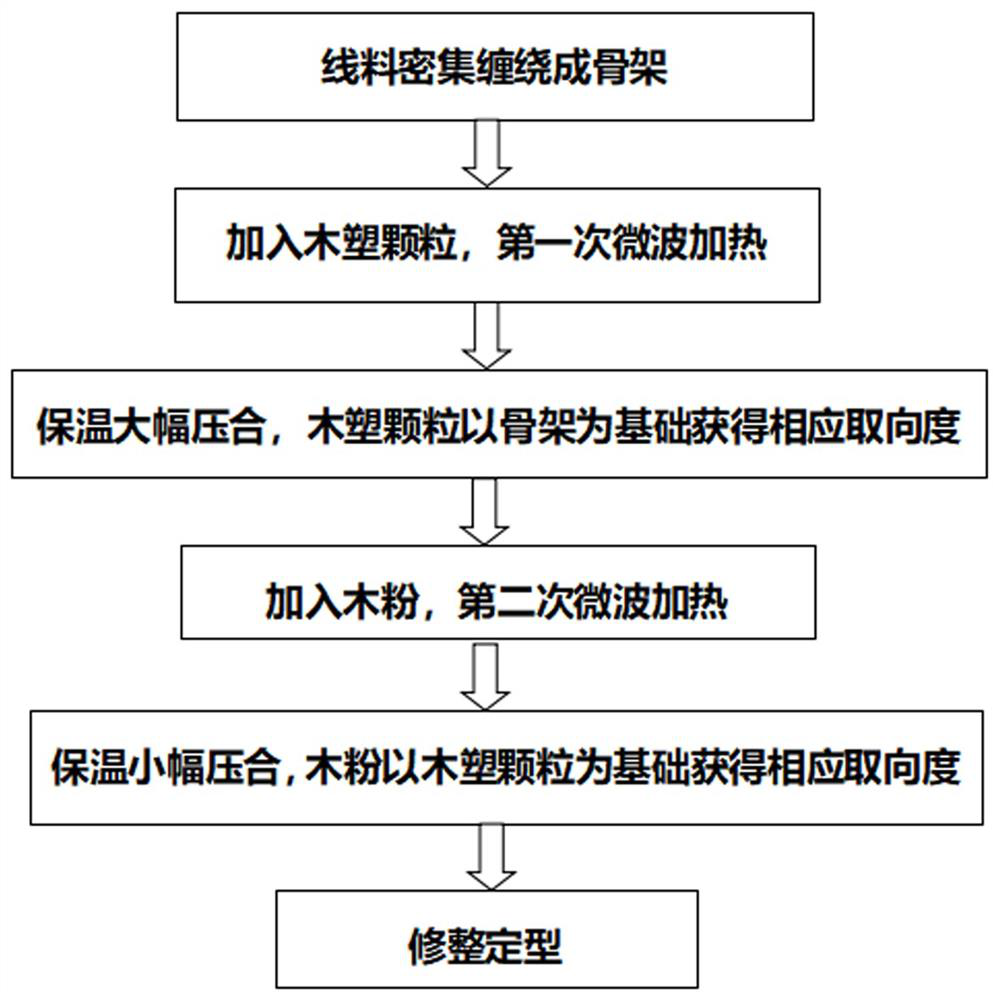

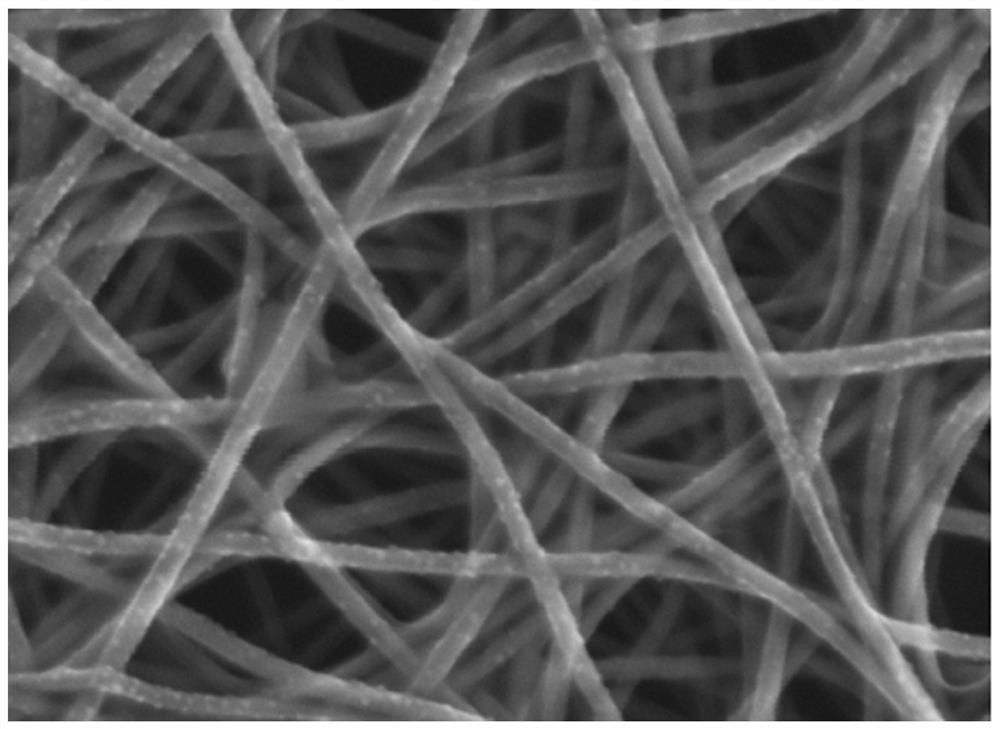

[0027] like figure 1As shown, a method for preparing glue-free self-integrated environmentally friendly wood-based panels by microwave pretreatment of wood flour. First, continuous copper wires are interlaced to form an internal honeycomb-shaped wood-based panel skeleton. The width of the wood-based panel is rectangular. Add easy-to-form wood-plastic granules at the central position, and at the same time, the wood-plastic panel shakes in the direction of the web plane until the wood-plastic granules reach the back of the wood-plastic panel skeleton. Equivalent physical properties of bending resistance improve the durability of wood-based panels. Specifically, crush and mix the straw and plastic particles that remove soil and sand impurities, and mix 2 parts of stabilizer, 3 parts of lubricant, 1 part of foaming agent and 5 parts of foaming agent. The flame retardant is mixed as an auxiliary material, and the auxiliary material is mixed with straw and plastic granules in a mass...

Embodiment 2

[0029] A method for preparing glue-free self-integrated environmentally friendly wood-based panels by microwave pretreatment of wood flour. First, silicon-based wires are used to form an internal honeycomb-shaped wood-based panel skeleton, and silicon-based wires are used to improve the flame retardancy and the overall hardness of the wood-based panel frame. The format is circular, and easy-to-form wood-plastic particles are added to the center of the front format of the wood-based panel. At the same time, the wood-plastic panel shakes in the plane direction of the format until the wood-plastic particles reach the back of the wood-based panel skeleton. The wood-plastic particles are made of fibers and fully mixed with plastic. , to ensure that its individual particles have the same physical properties of bending resistance as hardwood, and improve the durability of wood-based panels. Specifically, crush and mix the straw and plastic particles that remove soil and sand impurities...

Embodiment 3

[0031] A method for preparing glue-free self-integrated environmental-friendly wood-based panels by microwave pretreatment of wood flour. First, silicon-based wires doped with linear meltable materials are interlaced to form an internal honeycomb-shaped wood-based panel skeleton, preferably using low-density polystyrene Vinyl material, whose width is rectangular, add easy-to-form wood-plastic particles in the center of the front width of the wood-based panel, and at the same time, the wood-based panel shakes in the plane direction of the width until the wood-plastic particles reach the back of the wood-based panel skeleton. The wood-plastic particles are made of fibers and combined with The plastic is fully mixed to ensure that its individual particles have the same physical properties of bending resistance as hardwood, and improve the durability of the wood-based panel. Specifically, the straw and plastic particles that have been removed from soil and sand impurities are crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com