Preparation method of three-dimensional porous In2O3 nano-cube bread gas sensitive material

A technology of three-dimensional porous and gas-sensing materials, which is applied in the field of three-dimensional porous In2O3 nano-cube gas-sensing materials and their preparation, can solve the problems of film peeling and gas-sensing characteristics decline, and achieves the effect of firm bonding and improving gas-sensing characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

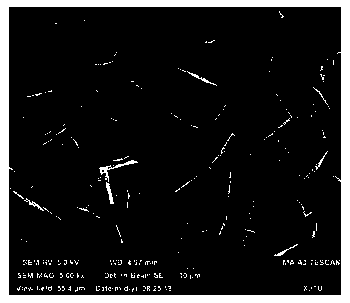

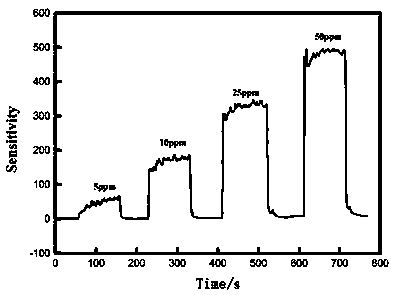

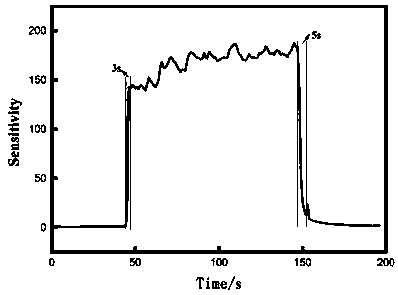

Image

Examples

Embodiment 1

[0019] The steps of a preparation method of a three-dimensional porous In2O3 nano cube bread gas-sensitive material are as follows:

[0020] 1. Cleaning of Ag interdigitated electrodes: place the electrodes in acetone and alcohol for ultrasonic treatment for 15 minutes, and then ultrasonically clean them in deionized water for 30 minutes;

[0021] 2. Growth seed layer: weigh 0.3g In(NO 3 ) 3 Add it to 5ml of absolute ethanol, stir ultrasonically for 30 minutes to obtain a seed layer solution, spray the seed layer solution evenly on the cleaned electrode sheet with a spray gun, and dry it at 60°C, and finally place the electrode sheet in a muffle furnace at 550°C Calcined for 90min;

[0022] 3. Growth In 2 o 3 : Weigh 0.8g In(NO 3 ) 3 , 2.4gNH 4 F and 0.2g of urea were placed in 50ml of deionized water, and the mixed solution was subjected to magnetic stirring and ultrasonic treatment for 15 minutes, respectively, to obtain a transparent growth liquid, which was poured i...

Embodiment 2

[0024] The steps of a preparation method of a three-dimensional porous In2O3 nano cube bread gas-sensitive material are as follows:

[0025] 1. Cleaning of Ag interdigitated electrodes: place the electrodes in acetone and alcohol for ultrasonic treatment for 15 minutes, and then ultrasonically clean them in deionized water for 30 minutes;

[0026] 2. Growth seed layer: weigh 0.1g In(NO 3 ) 3 Add it to 5ml of absolute ethanol, stir ultrasonically for 30 minutes to obtain a seed layer solution, spray the seed layer solution evenly on the cleaned electrode sheet with a spray gun, and dry it at 60°C, and finally place the electrode sheet in a muffle furnace at 600°C Calcined for 90min;

[0027] 3. Growth In 2 o 3 : Weigh 0.6g In(NO 3 ) 3 , 1.8g NH 4 F and 0.2g of urea were placed in 50ml of deionized water, and the mixed solution was subjected to magnetic stirring and ultrasonic treatment for 15 minutes, respectively, to obtain a transparent growth liquid, which was poured ...

Embodiment 3

[0029] The steps of a preparation method of a three-dimensional porous In2O3 nano cube bread gas-sensitive material are as follows:

[0030] 1. Cleaning of Ag interdigitated electrodes: place the electrodes in acetone and alcohol for ultrasonic treatment for 15 minutes, and then ultrasonically clean them in deionized water for 30 minutes;

[0031] 2. Growth seed layer: weigh 0.2g In(NO 3 ) 3 Add it to 5ml of absolute ethanol, and stir it ultrasonically for 30 minutes to obtain a seed layer solution. Use a spray gun to evenly spray the seed layer solution onto the cleaned electrode sheet and dry it at 60°C, and finally place the electrode sheet in a muffle furnace at 650°C Calcined for 90min;

[0032] 3. Growth In 2 o 3 : Weigh 0.7g In(NO 3 ) 3 , 2.1 g NH 4 F and 0.2g of urea were placed in 50ml of deionized water, and the mixed solution was subjected to magnetic stirring and ultrasonic treatment for 15 minutes, respectively, to obtain a transparent growth liquid, which wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com