Reflection film and backlight for liquid crystal display

A technology of reflective film and inorganic particles, applied in the field of reflective film, can solve the problem of insufficient luminance of reflective film, achieve the effect of improving reflectivity and luminance, and good anti-adsorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

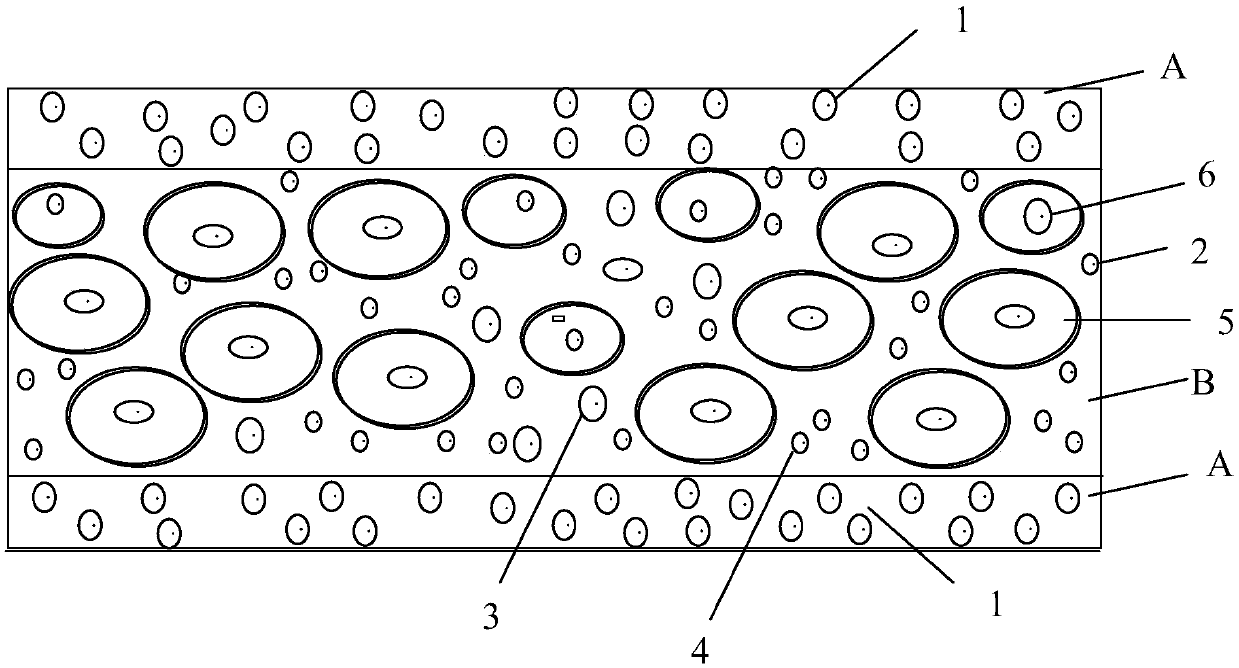

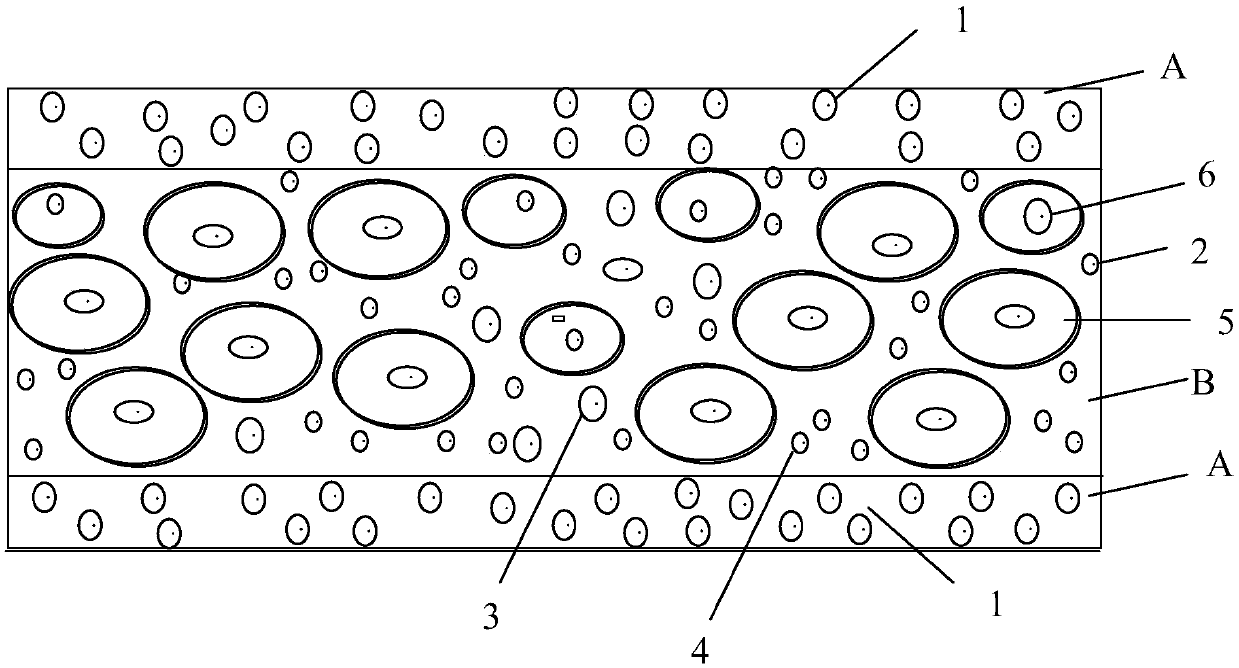

[0076] The preparation method of reflective film provided by the invention comprises the steps:

[0077] (1) Cast sheet: Three-layer co-extrusion process is adopted; the polyester resin, inorganic particles, additives, etc. Resin, incompatible resin, inorganic particles, additives, etc. are melted and extruded and introduced into the T-shaped die through a filter; then ABA three-layer co-extrusion is carried out to obtain a molten sheet;

[0078] (2) Stretching to form a film: first stretch the melted sheet obtained in step (1) longitudinally by 2 to 5 times; then transversely stretch by 3 to 5 times, heat-setting, winding, slitting and packaging to obtain a reflective film.

[0079] The reflective film prepared by the present invention is tested according to the following method:

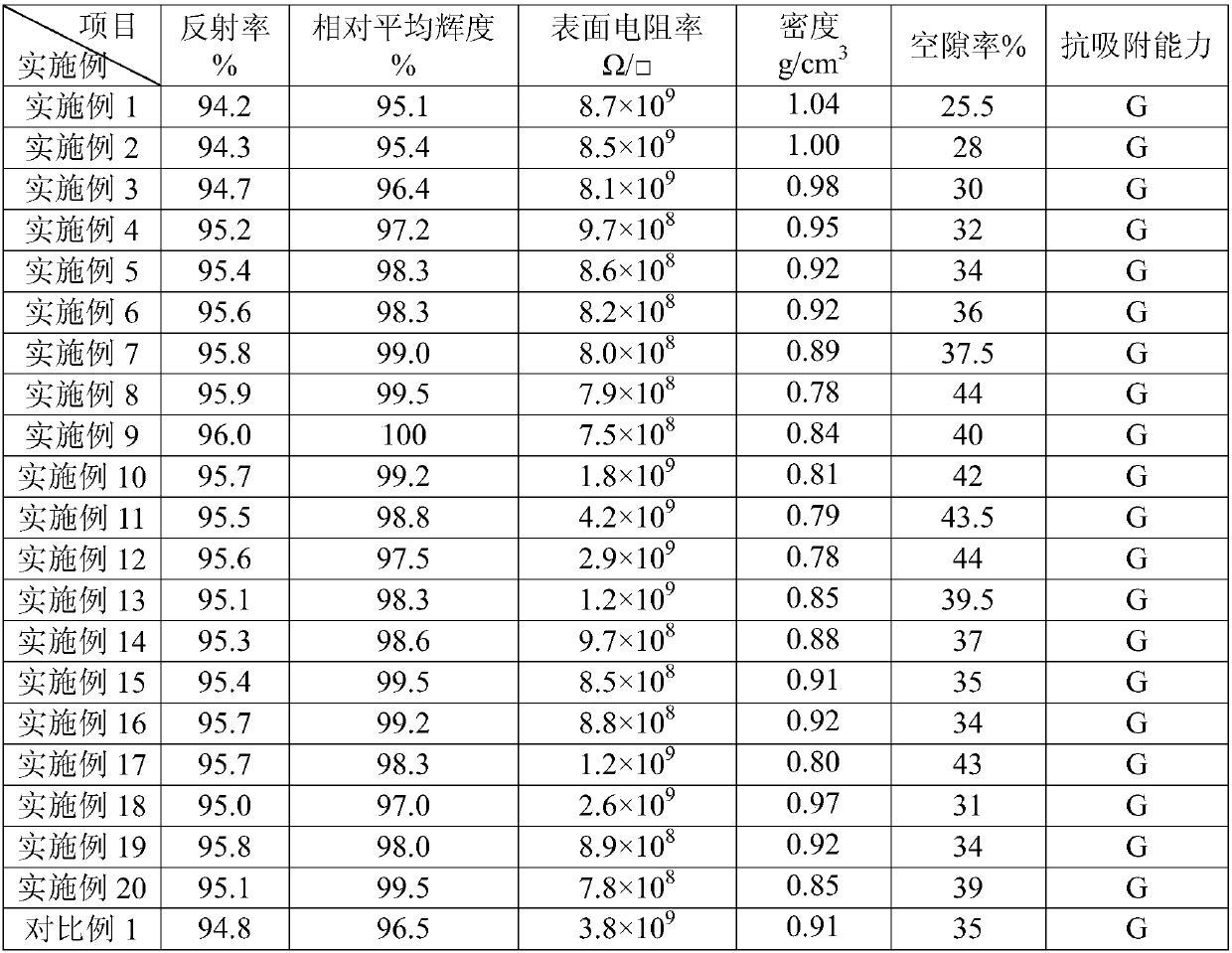

[0080] Reflectance: According to GB / T3979-2008 standard, using ColorQuest XE spectrophotometer (manufactured by Hunterlab), under the condition of D65 light source, the reflectance is tested throu...

Embodiment 1

[0090] The present invention provides a reflective film, the reflective film is an ABA three-layer structure, the B layer includes inorganic particles, and the inorganic particles form cells in the B layer; the B layer also includes an incompatible resin, the The incompatible resin forms cells in the B layer.

[0091] Layer A includes 72.7% PET, 20% silica particles with an average particle size of 3 μm, 2.8% ethylenediamine sulfonate terephthalate antistatic agent, 0.5% 2,6-tertiary butyl-4-methylphenol Hindered phenolic antioxidant, 4.0% MAH grafted SEBS (grafting rate ≥ 0.5%).

[0092] Layer B includes 73.7% PET with an intrinsic viscosity of 0.68dL / g, 5% rutile titanium dioxide inorganic particles with an average particle size of 1 μm, 5% polymethylpentene incompatible resin, and 4.5% with an average particle size of 0.5 μm Barium sulfate inorganic particles, 3.8% calcium carbonate inorganic particles, the average particle size is 0.8 μm, 4% MAH grafted SEBS (grafting rat...

Embodiment 2

[0094] As in the reflective film provided in Example 1, the B layer includes 73.7% PET, the intrinsic viscosity is 0.68dL / g, 5% rutile titanium dioxide inorganic particles, the average particle size is 0.4 μm, and 5% polymethylpentene is incompatible Resin, 4.5% barium sulfate inorganic particles, the average particle size is 2 μm, 3.8% calcium carbonate inorganic particles, the average particle size is 2 μm, 4% MAH grafted SEBS (grafting rate ≥ 0.5%) toughening agent, 2.0% sulfonic acid Ethylenediamine terephthalate antistatic agent, 1% Millad3988 (Milliken Company) nucleating agent, 1% PEG (molecular weight 20000) dispersant, and the percentages are percentages by weight. The thickness of the two A layers accounts for 12% of the total thickness, and the thickness of the B layer accounts for 88% of the total thickness. The thickness of the obtained reflective film is 225 μm, and the relevant properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com