Online assembly defect identification system and method

A defect identification and defect technology, applied in the field of online assembly defect identification system, can solve problems such as high product defect rate, product or assembly machine tool monitoring, and affecting the machine tool performance in the assembly workshop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

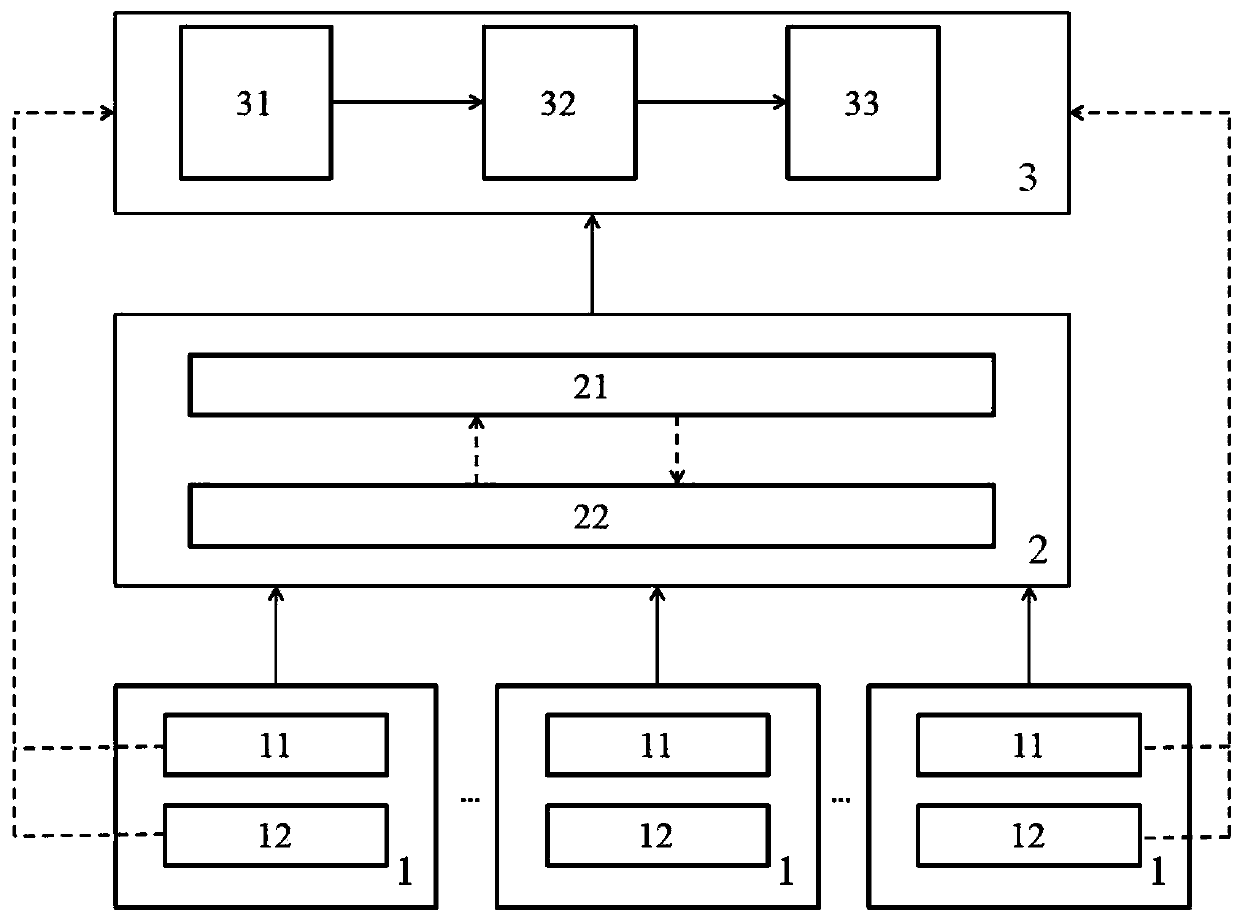

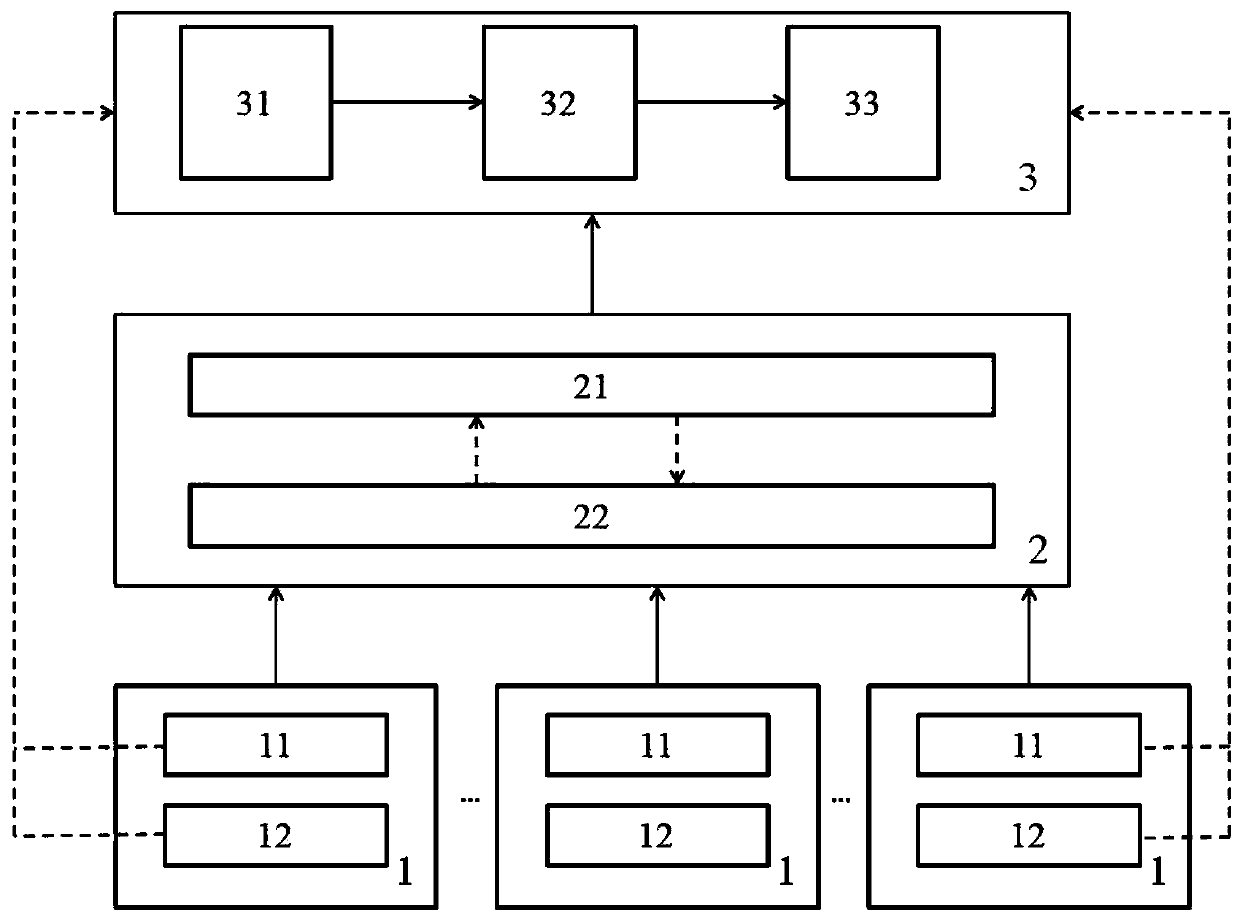

[0046] Refer to attached figure 1 , the present invention provides an online assembly defect recognition system and method thereof, the system is suitable for intelligent manufacturing workshops and is established based on B / S architecture, and includes several assembly stations 1, lower computer image processing modules 2 and upper computer The server module 3 will be specifically explained below one by one.

[0047] The several assembly stations 1 are interconnected to form a product assembly line, and the product to be tested moves through each assembly station 1 sequentially under the control of the host computer server module 3 to complete the assembly process; and for any assembly station, its side Both position sensors 11 and industrial cameras 12 are arranged vertically, wherein the position sensors 11 and the industrial cameras 12 are connected to the server module of the upper computer through communication, and the position sensors 11 are set at fixed marking points...

Embodiment approach 2

[0066] The present invention further provides an online assembly defect identification system and its method, which adopts the aforementioned online assembly defect identification system of the present invention, and includes the following steps:

[0067] Step 1: In the upper computer server module, build an assembly defect recognition model based on the PSO-SVM algorithm, and input the training sample library images of the assembly stations on the product assembly line for training and learning;

[0068] Step 2: On-site real-time collection of the image of the product to be tested on the assembly station after the assembly process is completed, and the image processing unit of the image processing module of the lower computer performs identification and segmentation, preprocessing, denoising and edge detection of the target area, thereby calculating and obtaining The initial feature set X=[X 1 ,X 2 ,X 3 ,X 4 ] T ;

[0069] Step 3: The upper computer server module adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com