Submodule for high-voltage long-pulse PSM power source

A long-pulse, sub-module technology, which is applied in the direction of electrical components, adjustment of electric variables, and output power conversion devices, can solve the problems of increasing transformer cost and installation space, increasing secondary windings, and low output voltage levels of power modules. Achieve the effect of increasing the output voltage level, increasing the power density, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

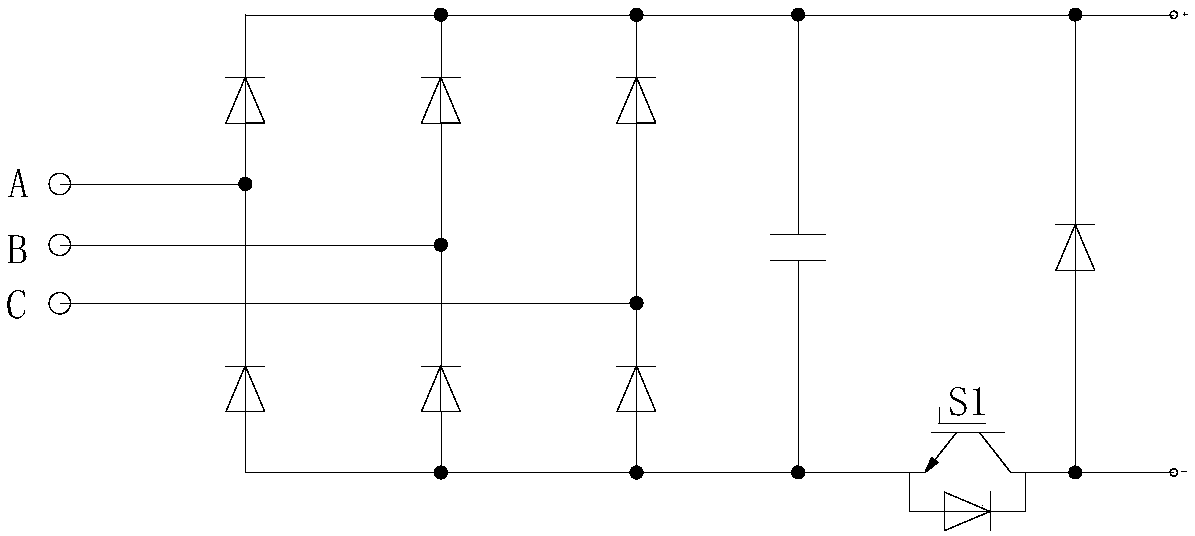

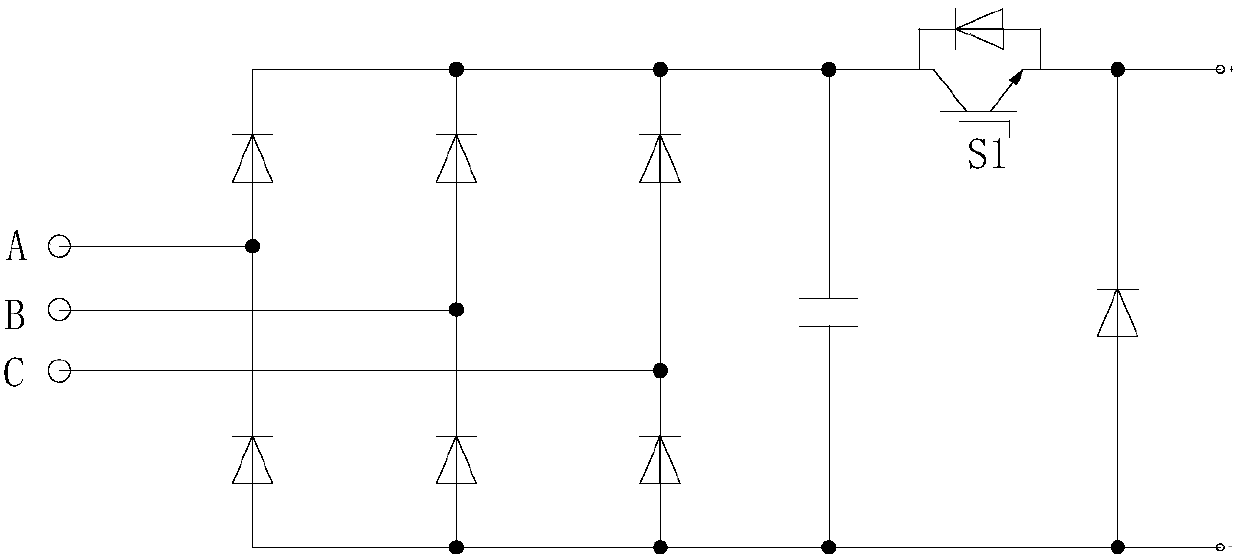

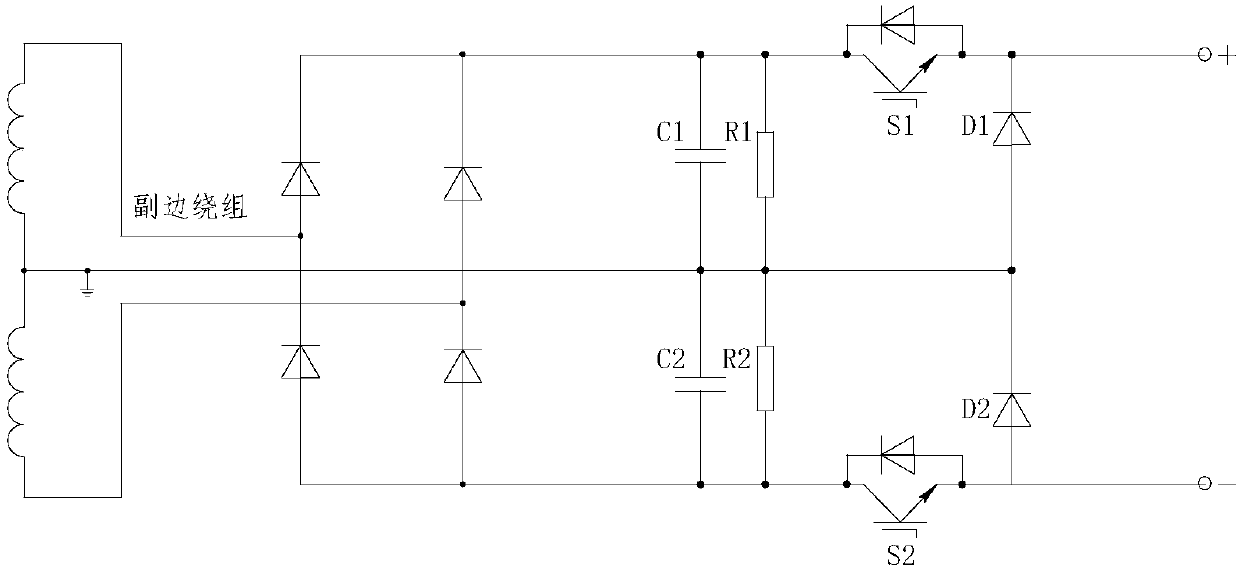

[0020] The present invention is used for the power supply module unit topological structure wiring mode of the high-voltage pulse power supply such as figure 2 , image 3 , Figure 4 , Figure 5 shown. in figure 2 , image 3 with Figure 4 , Figure 5 For the same topology, the difference is the wiring method. Both wiring methods have advantages and disadvantages. figure 2 In the wiring mode shown, if the midpoint of the two series capacitors C1 and C2 is connected to the neutral line of the transformer, the unit’s requirements for midpoint balance control will be reduced, but the cost of the transformer will be increased; image 3 In the wiring method shown, the transformer does not have a neutral wire, so the power supply unit will have high requirements on the neutral point balance control, which will undoubtedly increase the comple...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap