Method for preparing in-situ grapheme-coated metal oxide nanoflower structure on metal substrate

A graphene-wrapped, metal-based technology, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

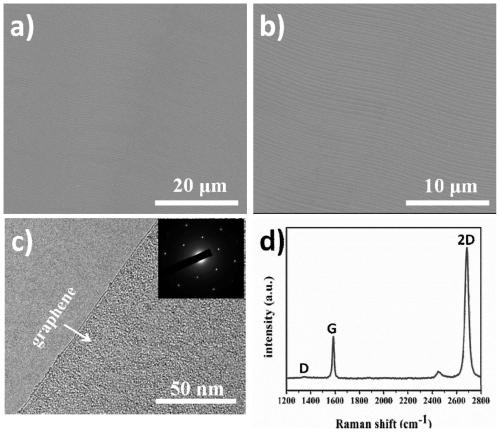

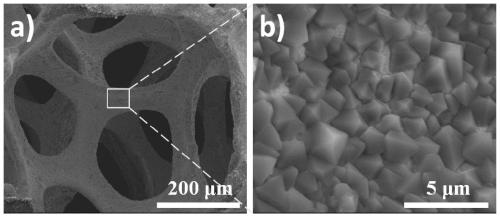

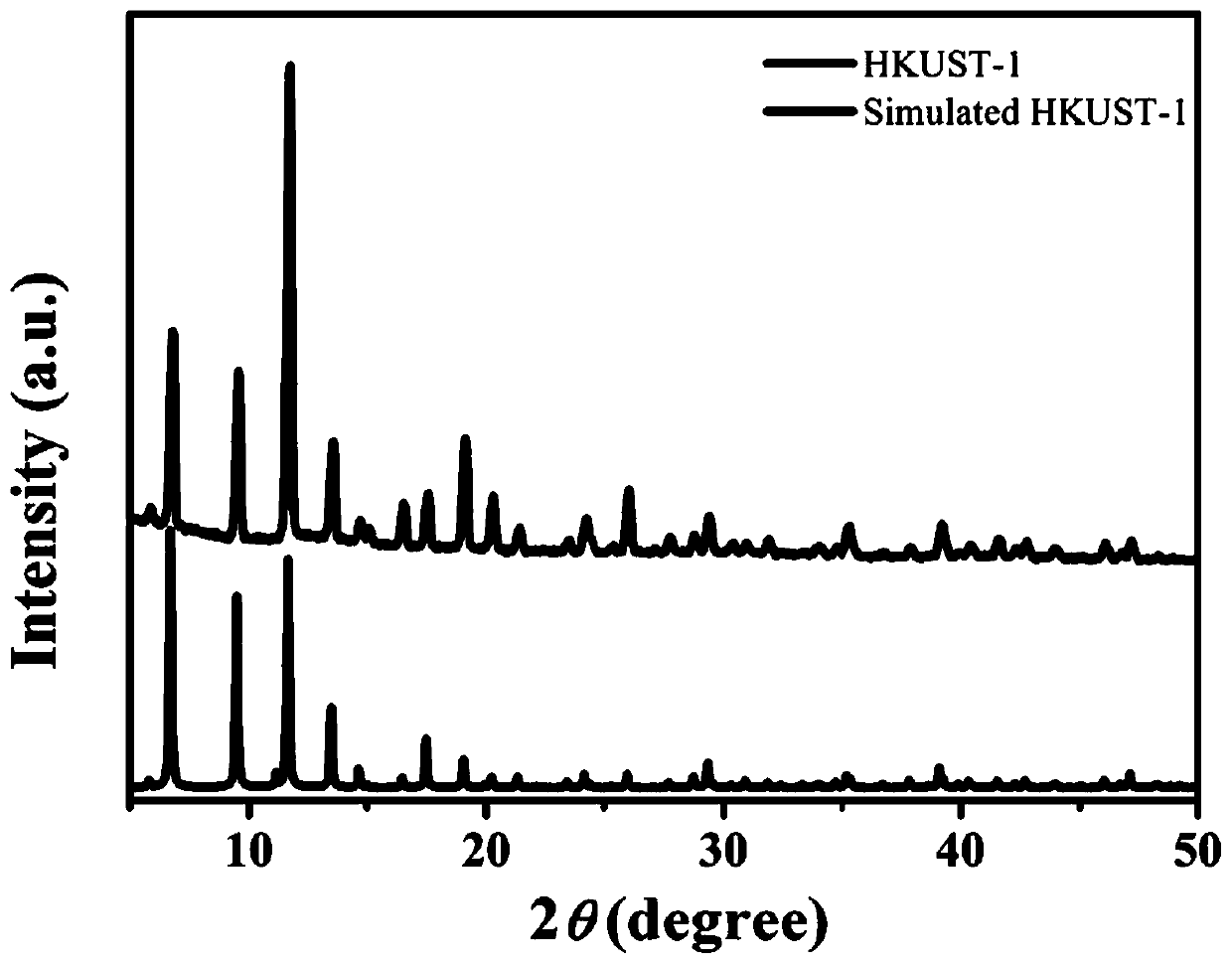

[0037] A preparation method for growing CuO nanoflowers on foamed copper. The method uses chemical vapor deposition (CVD) to grow graphene, then electrochemically grows HKUST-1, and uses lye soaking method to convert HKUST-1 to CuO Nanoparticles, the target product graphene-wrapped CuO nanoflower is finally obtained by the voltage pulse lye immersion method. The electrochemical OER performance test of the material prepared by the present invention shows that the target product has an overpotential of up to 10mA cm-1 at a current density of 10mA cm-1. 323mv, that is, the material has excellent OER catalytic activity. The preparation method includes the following steps:

[0038] ① Pretreatment of foamed copper substrate. Cut the foamed copper into 1 mm2, soak it in 10% acetic acid for 10 minutes to remove the oxide layer on the surface, wash it with pure water, and dry it with nitrogen for use. Furnace temperature is 40℃min -1 The heating rate was increased to 300°C and oxidized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com