Method and device for treating high-salinity wastewater by using rotary membrane evaporator

A membrane evaporator, high-salt wastewater technology, applied in chemical instruments and methods, water/sewage treatment, heating water/sewage treatment, etc., can solve problems such as blockage of the evaporator outlet, increased repair costs, and easy wear of the scraper. , to achieve the effect of convenient maintenance and replacement, reducing repair costs, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

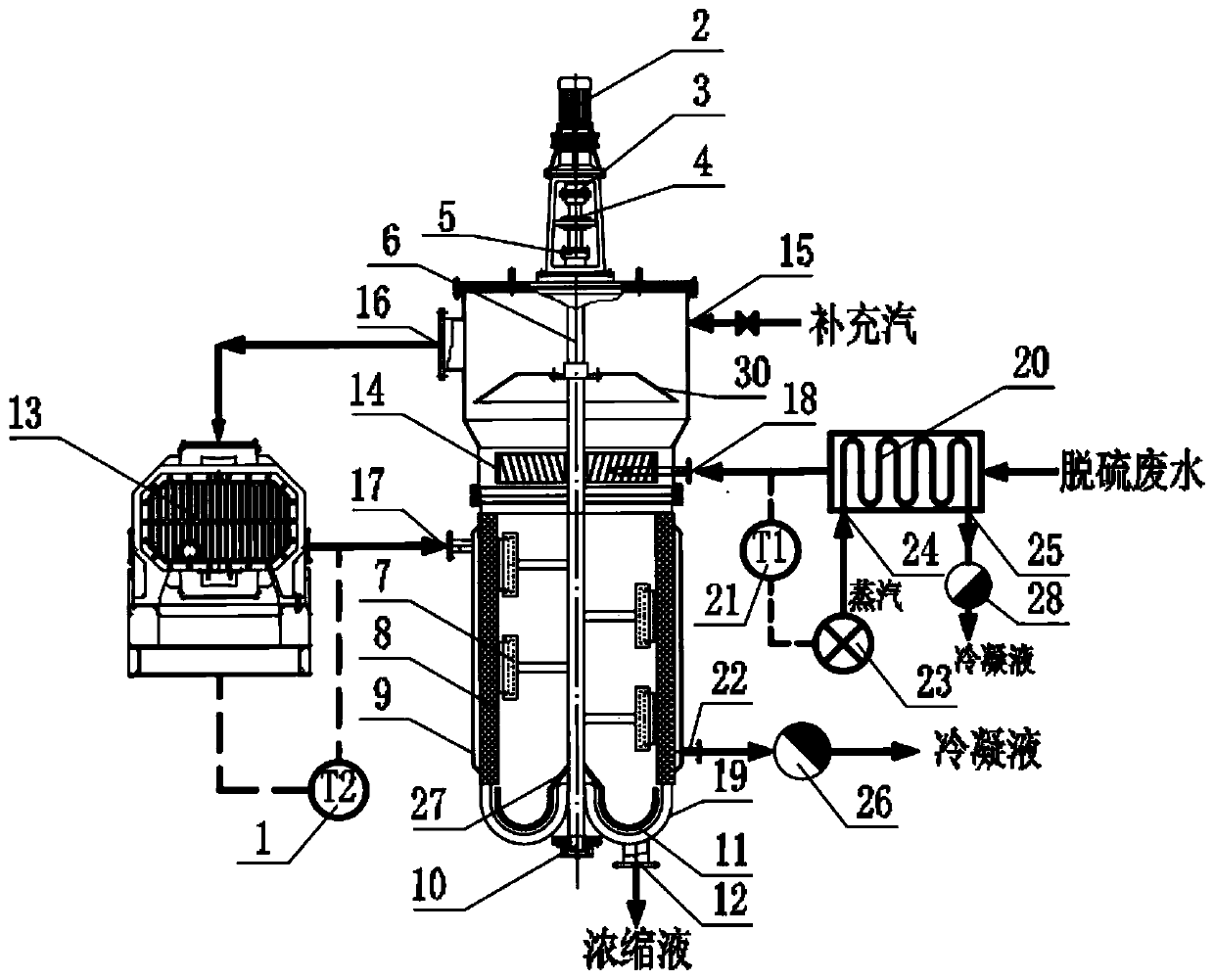

[0058] A device for treating high-salt wastewater by a rotary film evaporator, comprising a rotary film evaporator, a steam compressor 13 connected to a steam outlet 16 and a steam inlet 17 of the rotary film evaporator, and a rotary film evaporator A first steam trap 26 is arranged on the connecting pipeline of the heat exchanger 20 connected to the high-salt wastewater inlet 18 and the wastewater steam outlet 22 at the bottom of the rotary film evaporator.

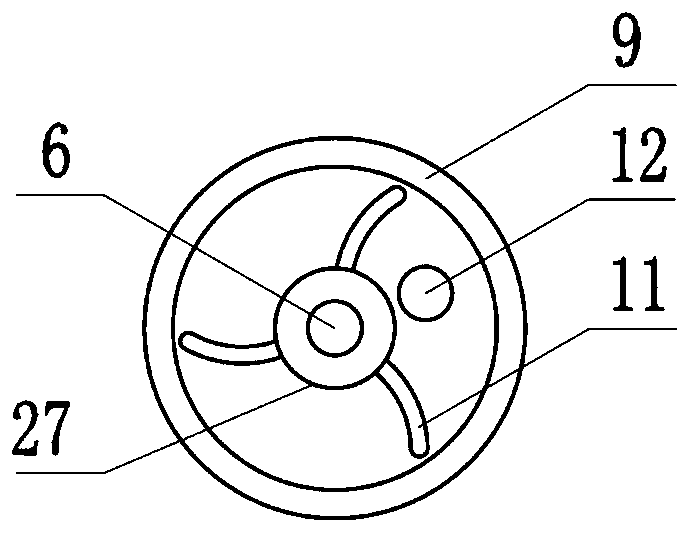

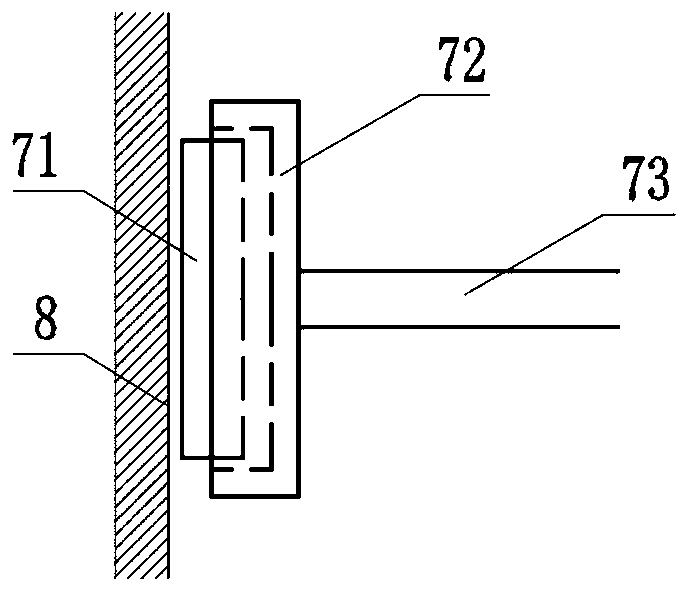

[0059] The driving device of the main shaft 6 in the rotary film evaporator includes a motor 2, a reducer 3, a coupling 4, a mechanical seal 5, a bearing, a bearing seat 10, and a bottom scraper 11. The rotary film evaporator adopts a vertical evaporation method. The motor 2, the reducer 3, the coupling 4, the mechanical seal 5, the bearing and the bearing seat 10 are on a vertical line with the main shaft 6 and connected with the main shaft 6. The motor 2 is connected with the reducer 3 , the lower part of the reducer 3...

Embodiment 2

[0067] Supplement raw steam with a pressure of 0.08MPa at the steam inlet and a temperature of 102°C. After the steam is compressed by the compressor 13, the temperature increases by about 10°C to heat the evaporator. The evaporator treats 1 t / h of high-salt wastewater, and the temperature of the steam outlet 22 of the high-salt wastewater is about 106°C.

[0068] The working process of the device of the present invention is as follows:

[0069] (1) Open the valve at the supplementary steam inlet 15 to make the raw steam fill the shell of the evaporator. Turn on the steam compressor 13 to compress the raw steam and increase the steam temperature by about 10°C. The compressed steam heats the inner casing 8 . The second thermometer detects the temperature of the steam compressed by the compressor 13. If the temperature is too high or too low, the frequency of the compressor 13 is adjusted to adjust the temperature.

[0070] (2) The motor 2 is started and decelerated by the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com