Polysiloxazane and preparation method thereof

A technology for polysiloxazane and silazane, which is applied in the field of polysiloxsilazane and its preparation, can solve the problems of tediousness, difficulty in realizing polymer structure regulation, affecting high temperature performance, etc., and achieves high purity and high yield. High rate and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

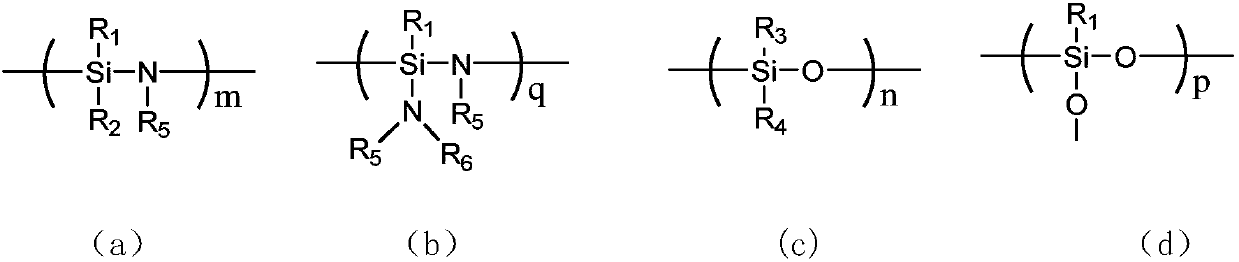

[0060] 10L three-necked flask, after nitrogen replacement, add 5000ml toluene, add methylhydrogen dichlorosilane (CH 3 SiHCl 2 ) 460g, methylvinyldichlorosilane 56g, methyltrichlorosilane 1000g, under mechanical stirring, feed ammonia gas into the reaction solution until the system pH≥10. Filtrate under the protection of nitrogen, remove the ammonium chloride produced by the reaction, and remove the solvent in the solution by rotary evaporation to obtain 630 g of Si-H polysilazane (coded as PSN1), the structure of which is as follows:

[0061]

[0062] The above structure was verified by NMR and infrared detection.

Embodiment 2

[0064] 10L three-necked flask, after nitrogen replacement, add 5000ml toluene, add methylhydrogen dichlorosilane (CH 3 SiHCl 2 ) 100g, dimethyldichlorosilane 400g, methyltrichlorosilane 1000g, under mechanical stirring, feed ammonia gas into the reaction solution until the system pH≥10. Filtrate under the protection of nitrogen, remove the ammonium chloride produced by the reaction, and remove the solvent in the solution by rotary evaporation to obtain 607g of Si-H polysilazane (coded as PSN2), the structure is as follows:

[0065]

[0066] The above structure was verified by NMR and infrared detection.

Embodiment 3

[0068] 10L three-necked flask, after nitrogen replacement, add 5000ml toluene, add methylhydrogen dichlorosilane (CH 3 SiHCl 2 ) 460g, methylvinyldichlorosilane 800g, under mechanical stirring, feed ammonia gas into the reaction solution until the system pH ≥ 10. Filtrate under the protection of nitrogen, remove the ammonium chloride produced by the reaction, and remove the solvent in the solution by rotary evaporation to obtain 456g of Si-H polysilazane (coded as PSN3), the structure is as follows:

[0069]

[0070] Wherein, x and y are natural numbers greater than 1.

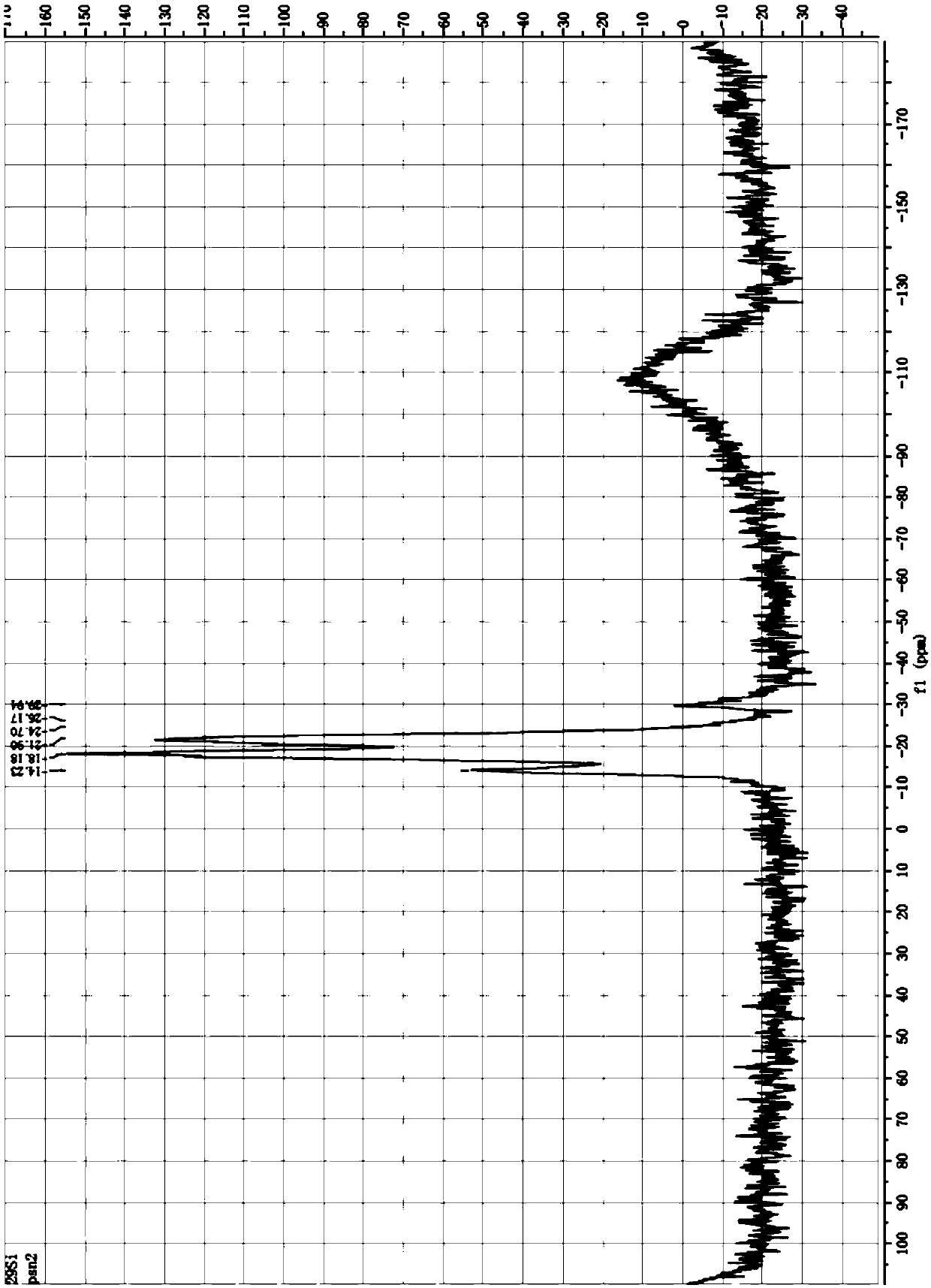

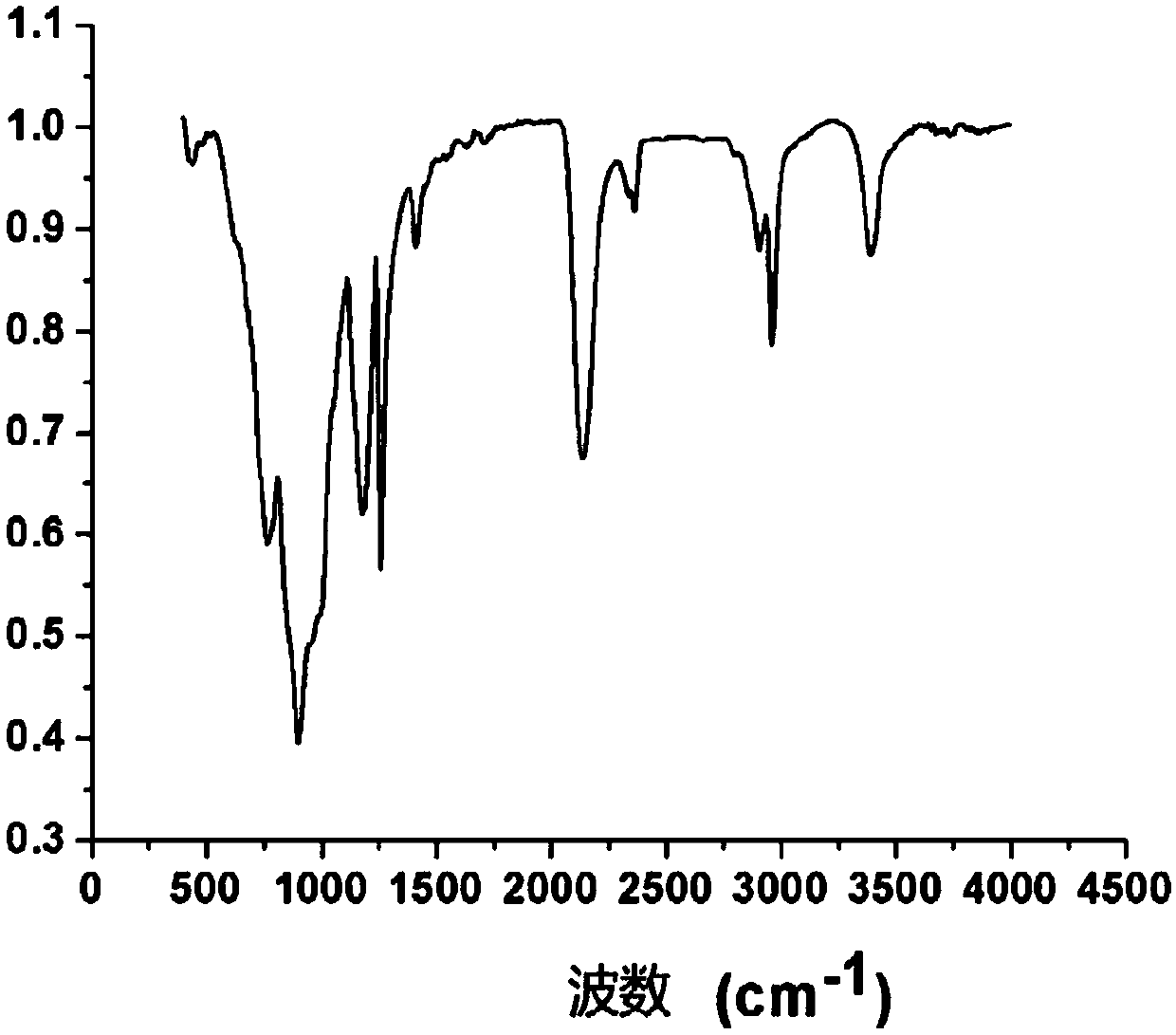

[0071] The above structure has been verified by nuclear magnetic and infrared detection, and as an exemplary illustration, the corresponding drawings are provided in the accompanying drawings of the description. figure 1 is PSN3 29 Si NMR spectrum, figure 2 is the infrared spectrum of PSN3.

[0072] Synthesis of Polysiloxazane

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com