Antibacterial sublimation transfer-printing wood-grain powder coating composition

A powder coating and composition technology, applied in powder coatings, polyester coatings, antifouling/underwater coatings, etc., can solve problems such as failure, high temperature and weakening of sublimation transfer wood grain powder transfer, and achieve heat resistance. Improved stability, antibacterial resistance to bacteria, and destruction-avoidance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

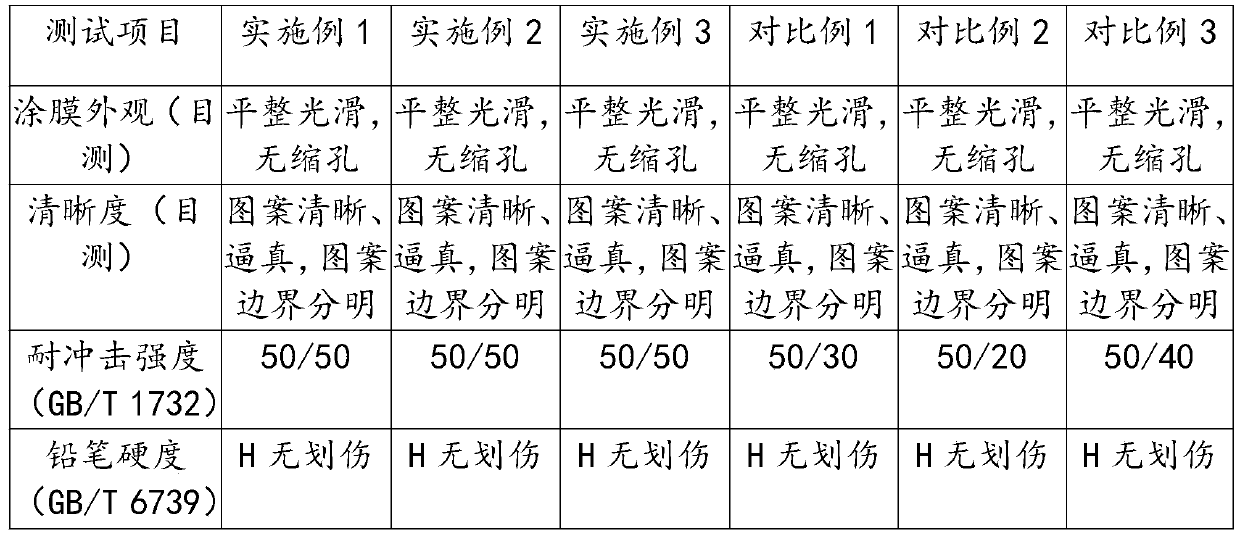

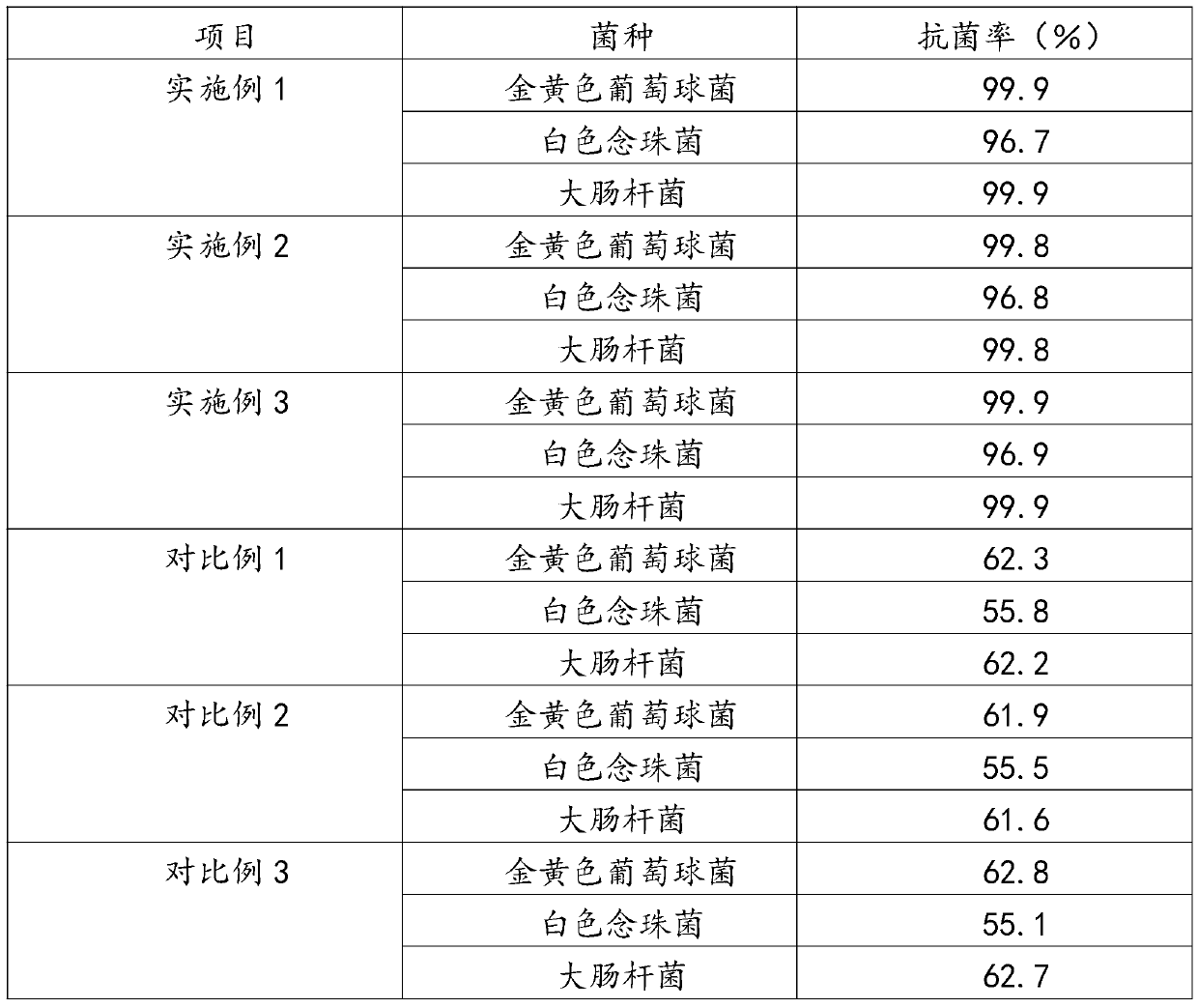

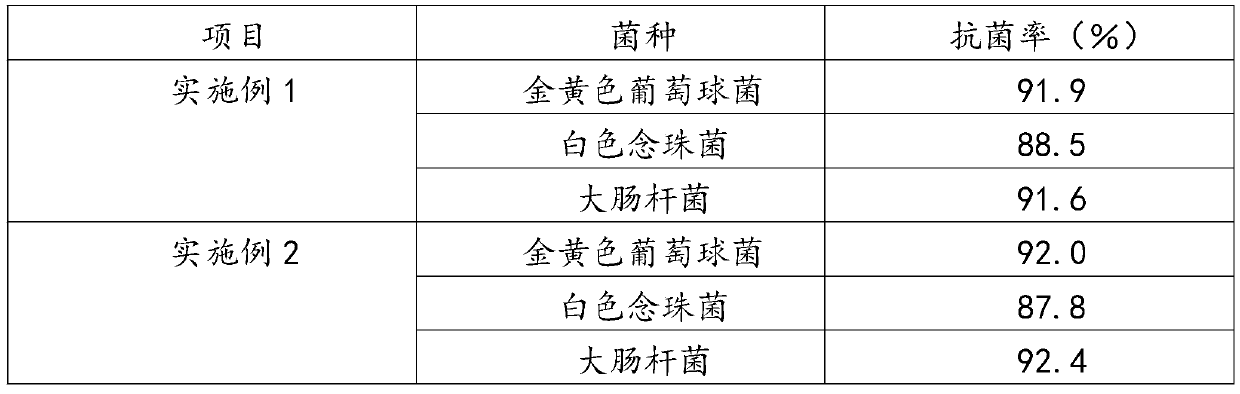

Examples

Embodiment 1

[0033] (1) Preparation of base powder:

[0034] A kind of base powder of antibacterial sublimation transfer printing wood grain powder coating composition, comprises following weight component raw material:

[0035] Polyester resin 70%

[0036] TGIC 6%

[0037] Leveling agent 1.5%

[0038] Brightening agent 1%

[0039] Benzoin 0.8%

[0040] Curing Accelerator 2%

[0041] Filler 15.7%

[0042] Pigment 3%

[0043] Polyester resin: Anhui Shenjian New Material Co., Ltd. SJ4E;

[0044] TGIC: product of Huangshan Huahui Technology Co., Ltd.;

[0045] Leveling agent: PV88 from German Dexinli Chemical;

[0046] Brightening agent: Ningbo Nanhai Chemical Co., Ltd. 701B;

[0047] Curing accelerator: SA7318 from Lu'an Jietongda New Material Co., Ltd.;

[0048] Precipitated barium sulfate: Precipitated barium sulfate from Shaanxi Fuhua Chemical Co., Ltd.;

[0049] Titanium dioxide: ZR940+ from Jiangsu Zhentai Chemical Co., Ltd.

[0050] After batching the ingredients according...

Embodiment 2

[0070] (1) Preparation of base powder:

[0071] A kind of base powder of antibacterial sublimation transfer printing wood grain powder coating composition, comprises following weight component raw material:

[0072] Polyester resin 60%

[0073] TGIC 5%

[0074] Leveling agent 1%

[0075] Brightening agent 1%

[0076] Benzoin 0.5%

[0077] Curing Accelerator 1%

[0078] Filler 21.5%

[0079] Pigment 10%

[0080] Polyester resin: Anhui Shenjian New Material Co., Ltd. SJ4E;

[0081] TGIC: product of Huangshan Huahui Technology Co., Ltd.;

[0082] Leveling agent: PV88 from German Dexinli Chemical;

[0083] Brightening agent: Ningbo Nanhai Chemical Co., Ltd. 701B;

[0084] Curing accelerator: SA7318 from Lu'an Jietongda New Material Co., Ltd.;

[0085] Precipitated barium sulfate: Precipitated barium sulfate from Shaanxi Fuhua Chemical Co., Ltd.;

[0086] Titanium dioxide: ZR940+ from Jiangsu Zhentai Chemical Co., Ltd.

[0087] After batching the ingredients according to...

Embodiment 3

[0107] (1) Preparation of base powder:

[0108] A kind of base powder of antibacterial sublimation transfer printing wood grain powder coating composition, comprises following weight component raw material:

[0109] Polyester resin 50%

[0110] TGIC 4%

[0111] Leveling agent 0.5%

[0112] Brightening agent 0.5%

[0113] Benzoin 0.2%

[0114] Curing Accelerator 0.5%

[0115] Filler 29.3%

[0116] Pigment 15%

[0117] Polyester resin: Anhui Shenjian New Material Co., Ltd. SJ4E;

[0118] TGIC: product of Huangshan Huahui Technology Co., Ltd.;

[0119] Leveling agent: PV88 from German Dexinli Chemical;

[0120] Brightening agent: Ningbo Nanhai Chemical Co., Ltd. 701B;

[0121] Curing accelerator: SA7318 from Lu'an Jietongda New Material Co., Ltd.;

[0122] Precipitated barium sulfate: Precipitated barium sulfate from Shaanxi Fuhua Chemical Co., Ltd.;

[0123] Titanium dioxide: ZR940+ from Jiangsu Zhentai Chemical Co., Ltd.

[0124] After batching the ingredients acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com