Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display module

A technology of liquid crystal alignment agent and polymer, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, can solve the problems of environmental resistance and adhesion to be improved, and achieve the effect of good environmental resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

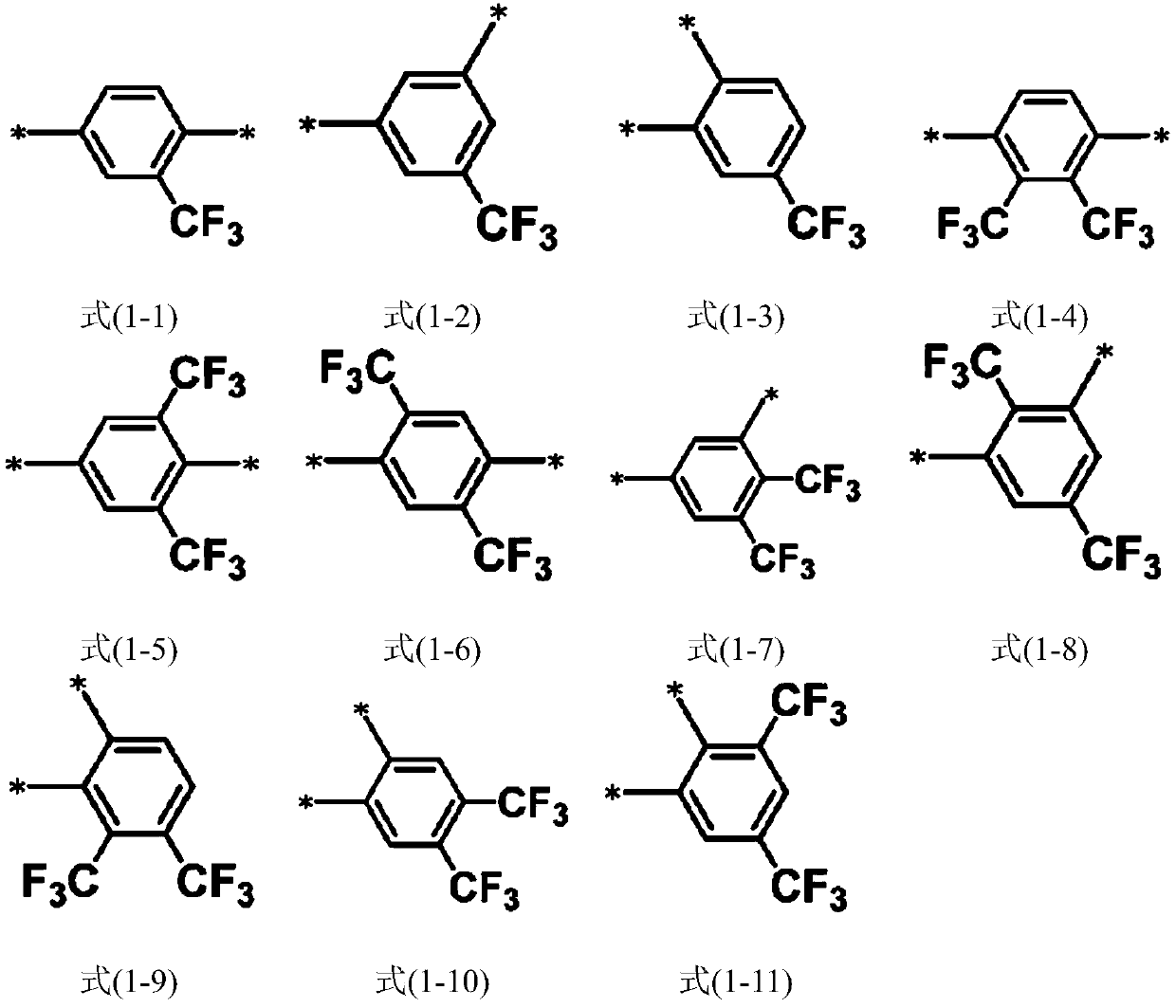

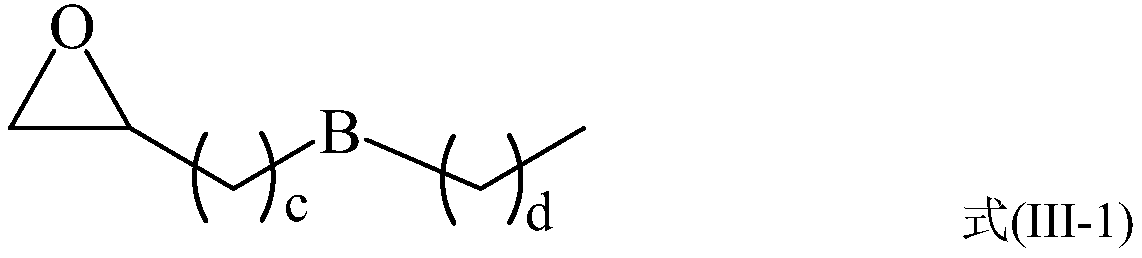

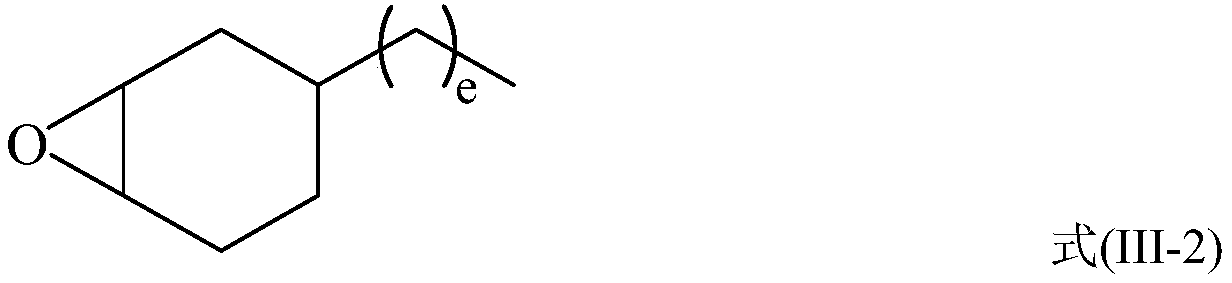

Method used

Image

Examples

preparation example Construction

[0147] [Method for producing polymer (A)]

[0148] The polymer (A) may include at least one of polyamic acid polymer (A1) and polyimide polymer (A2). In addition, the polymer (A) may further include a polyimide-based block copolymer. The preparation methods of the above-mentioned various polymers are further described below.

[0149]

[0150] The method for preparing this polyamic acid polymer (A1) is first the first mixture is dissolved in the solvent, wherein the first mixture includes tetracarboxylic dianhydride component (a1) and diamine component (a2), and in 0 The polycondensation reaction is carried out at a temperature ranging from 100°C to 100°C. After reacting for 1 hour to 24 hours, the reaction solution is distilled under reduced pressure with an evaporator to obtain polyamic acid. Alternatively, the reaction solution is poured into a large amount of poor solvent to obtain a precipitate. Then, the precipitate is dried under reduced pressure to obtain polyamic...

Synthetic example A1-1

[0303] A nitrogen inlet, a stirrer, a condenser, and a thermometer were arranged on a four-necked conical flask with a volume of 500 milliliters, and nitrogen was introduced. Then, in a four-necked conical flask, add 0.005 moles of a2-1-1 shown in Table 1-1, 0.02 moles of a2-2-1, 0.025 moles of a2-3-2 and 80 grams of N-formazan base-2-pyrrolidone (N-methyl-2-pyrrolidone, referred to as NMP), and stirred at room temperature until dissolved. Next, 0.05 mol of a1-1 shown in Table 1 and 20 g of NMP were added and reacted at room temperature for 2 hours. After the reaction was finished, the reaction solution was poured into 1500 milliliters of water, so that the polymer was precipitated. Then, the obtained polymer was filtered, washed with methanol and filtered three times, placed in a vacuum oven, and dried at a temperature of 60° C. to obtain the polymer (A1-1).

[0304]

[0305] Synthesis Examples A1-2 to A1-13 and Comparative Synthesis Examples A1-14 to A1-16 are to prepare...

Synthetic example A2-1

[0307] A nitrogen inlet, a stirrer, a condenser, and a thermometer were arranged on a four-necked conical flask with a volume of 500 milliliters, and nitrogen was introduced. Then, in the four-necked conical flask, add 0.005 mole of a2-1-1 shown in Table 2-1, 0.02 mole of a2-2-1, 0.025 mole of a2-3-2 and 80 grams of NMP, and Stir at room temperature until dissolved. Next, 0.05 mol of a1-1 shown in Table 2-1 and 20 g of NMP were added. After reacting at room temperature for 6 hours, 97 g of NMP, 0.05 mol of acetic anhydride and 0.1 mol of pyridine were added, the temperature was raised to 120° C., and stirring was continued for 2 hours to carry out imidization reaction. After the reaction was finished, the reaction solution was poured into 1500 milliliters of water, so that the polymer was precipitated. Then, the obtained polymer was filtered, washed with methanol and filtered three times, placed in a vacuum oven, and dried at a temperature of 60° C. to obtain the polymer (A2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap