Grease composition and preparation method thereof

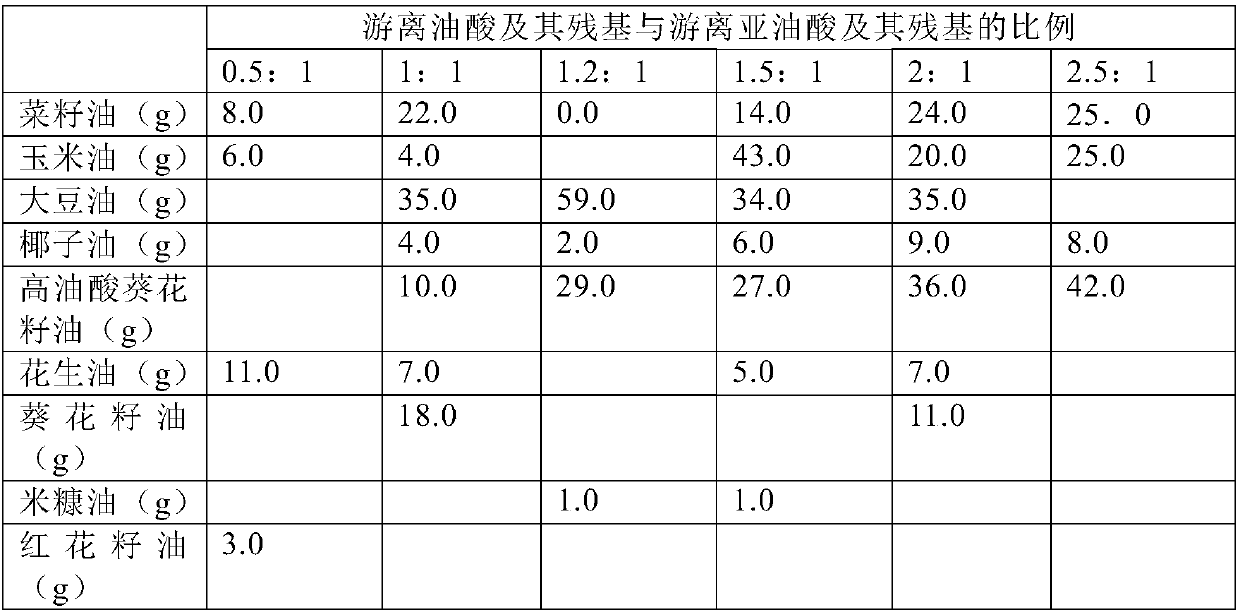

A technology of oil composition and fat mixture, which is applied in the direction of edible oil/fat, food science, fatty acid production, etc., and can solve problems such as incomplete fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] In one embodiment, the present invention provides the preparation method of above-mentioned grease composition, described method comprises the steps:

[0072] (i) Alcoholysis of triglycerides containing palmitic acid with alcohols having 1-6 carbon atoms to obtain oil A containing 2-monoglyceride palmitate, wherein, based on the glycerol containing palmitic acid The triglyceride comprises at least 40 mol%, preferably at least 45 mol%, more preferably at least 50 mol% palmitic acid residues, based on all acyl groups in the triester;

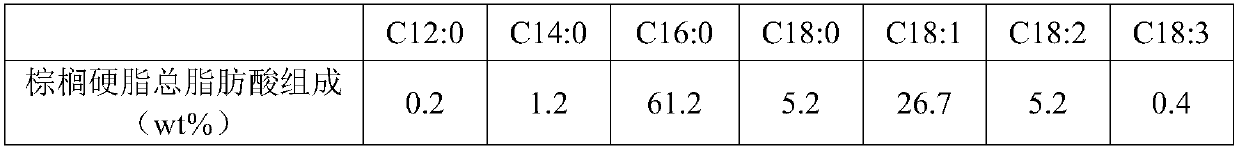

[0073](ii) Preparation of fat mixture B containing oleic acid or its non-glycerides and linoleic acid or its non-glycerides from oleic acid or its non-glycerides and linoleic acid or its non-glycerides; Prepare the fat mixture B containing oleic acid or its non-glycerides and linoleic acid or its non-glycerides from fats and oils of non-glycerides and linoleic acid or its non-glycerides;

[0074] Wherein, relative to the total weight of th...

Embodiment 1

[0118] Example 1: The target fat composition prepared by fat mixture B with different ratios of free oleic acid and its residues to free linoleic acid and its residues

[0119] At 52° C., 100 g of palm stearin shown in Table 3 below (based on the total acyl groups in palm stearin, the palm stearin contains 61 mol% of palmitic acid) was dissolved in 100 ml of acetone, and then Add 50ml absolute ethanol and stir. Next, at 52° C., 2 wt % Lipozyme RM IM (2 g) enzyme preparation (Novozymes) of palm stearin was added to react for 48 hours. Subsequently, the reaction was terminated by removing lipase, and excess acetone and ethanol were removed from the obtained product by vacuum distillation at 45° C.; the residue was collected to obtain fat A containing 2-monoglyceride palmitate.

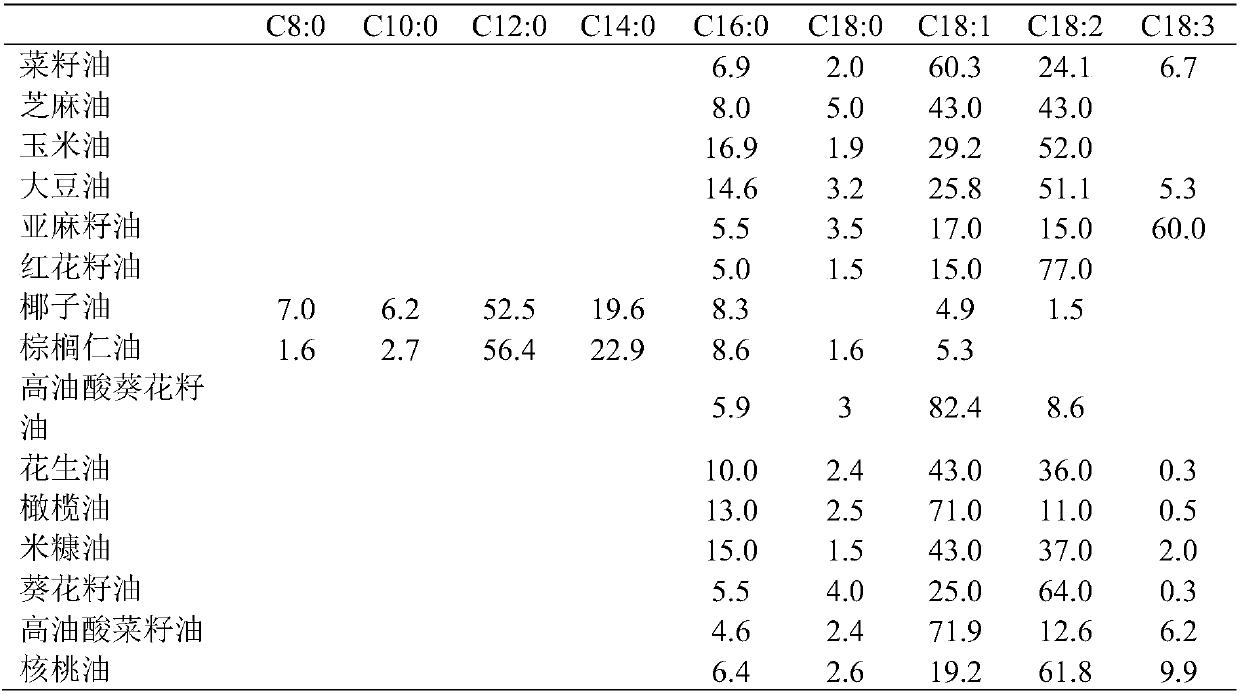

[0120] Table 3 Composition of Palm Stearin Containing 61 mol % Palmitic Acid Based on Total Acyl Groups in Palm Stearin

[0121]

[0122] *C12:0, C14:0, C16:0, and C18:0 refer to saturated fatty aci...

Embodiment 2

[0129] Example 2: Prepare the target oil composition by mixing different proportions of oil A and fat mixture B

[0130] At 52° C., 200 g of palm stearin as shown in Table 3 above (wherein, based on the total acyl groups in palm stearin, the palm stearin contains 61 mol% of palmitic acid) was dissolved in 200 ml of acetone, and then 100 ml of absolute ethanol was added thereto and stirred. Next, at 52° C., 2 wt % Lipozyme RM IM (4 g) enzyme preparation (Novozymes) of palm stearin was added to react for 48 hours. Subsequently, the reaction was terminated by removing lipase, and excess acetone and ethanol were removed from the obtained product by vacuum distillation at 45° C.; the residue was collected to obtain fat A containing 2-monoglyceride palmitate.

[0131] Fat mixture B was obtained by mixing oleic acid (800 g) with linoleic acid (800 g). Weigh grease A (100g), add 100g, 200g, 300g, 400g, 500g of fat mixture B respectively, that is, the mass ratio of grease A to fat mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com