Dynamic solvent-responsive nanofiber-based flexible transparent composite film and its preparation method

A nanofiber membrane, nanofiber technology, applied in fiber processing, fiber type, textile and papermaking, etc., to achieve the effect of simple process, suitable strength and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

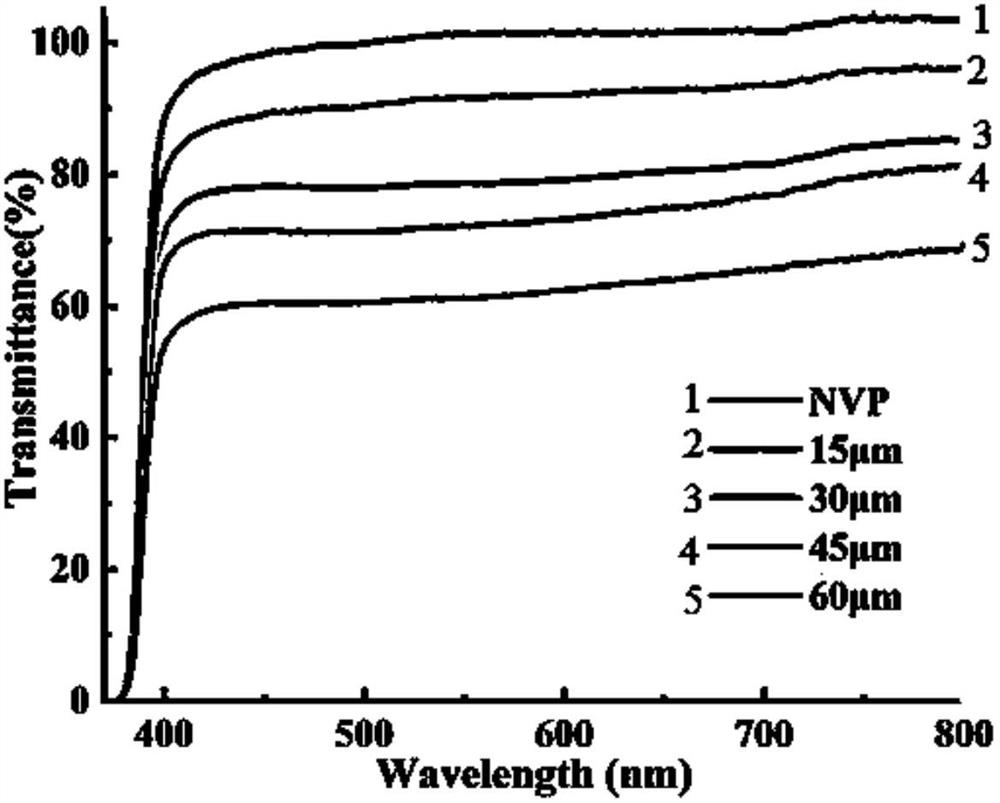

[0051]a) Add the NVP monomer solution, the initiator 2,2-dimethoxy-2-phenylacetophenone, and the crosslinking agent N,N-methylenebisacrylamide in a ratio of 500:1:1 In a 25mL beaker, stir well with a glass rod to obtain a uniformly mixed NVP polymerization solution, then cut the nanofiber film with a thickness of 60 μm into a size of 6cm×6cm and put it in the NVP polymerization solution for full infiltration.

[0052] b) Evenly mix polydimethylsiloxane (PDMS) and curing agent in a ratio of 10:1, then pour it into a petri dish with a diameter of 10 cm, and transfer it to an oven at a certain temperature for curing after vacuum degassing After 2 hours, a transparent and elastic PDMS substrate was formed, which was lifted for later use.

[0053] c) Take out the fully infiltrated nanofiber membrane from the NVP polymerization solution and place it on the PDMS elastic substrate, put the two together in a vacuum oven to eliminate the air bubbles between the interfaces, and make the ...

Embodiment 2

[0056] a) Add the NVP monomer solution, the initiator 2,2-dimethoxy-2-phenylacetophenone, and the crosslinking agent N,N-methylenebisacrylamide in a ratio of 250:1:1 to In a 25mL beaker, stir well with a glass rod to obtain a uniformly mixed NVP polymerization solution, then cut the nanofiber film with a thickness of 60 μm into a size of 6cm×6cm and put it in the NVP polymerization solution for full infiltration.

[0057] b) Evenly mix polydimethylsiloxane (PDMS) and curing agent in a ratio of 10:1, then pour it into a petri dish with a diameter of 10 cm, and transfer it to an oven at a certain temperature for curing after vacuum degassing After 2 hours, a transparent and elastic PDMS substrate was formed, which was lifted for later use.

[0058] c) Take out the fully infiltrated nanofiber membrane from the NVP polymerization solution and place it on the PDMS elastic substrate, put the two together in a vacuum oven to eliminate the air bubbles between the interfaces, and make ...

Embodiment 3

[0061] a) Add the NVP monomer solution, the initiator 2,2-dimethoxy-2-phenylacetophenone, and the crosslinking agent N,N-methylenebisacrylamide in a ratio of 100:1:1 to In a 25mL beaker, stir well with a glass rod to obtain a uniformly mixed NVP polymerization solution, then cut the nanofiber film with a thickness of 60 μm into a size of 6cm×6cm and put it in the NVP polymerization solution for full infiltration.

[0062] b) Evenly mix polydimethylsiloxane (PDMS) and curing agent in a ratio of 10:1, then pour it into a petri dish with a diameter of 10 cm, and transfer it to an oven at a certain temperature for curing after vacuum degassing After 2 hours, a transparent and elastic PDMS substrate was formed, which was lifted for later use.

[0063] c) Take out the fully infiltrated nanofiber membrane from the NVP polymerization solution and place it on the PDMS elastic substrate, put the two together in a vacuum oven to eliminate the air bubbles between the interfaces, and make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com