A kind of tungsten carbide/porous carbon composite material and its preparation method and application in electrochemical hydrogen production

A composite material, tungsten carbide technology, used in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of easy aggregation of catalysts, weak force, decreased catalytic activity, etc., to achieve enhanced The effect of hydrogen production efficiency, increased stability, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

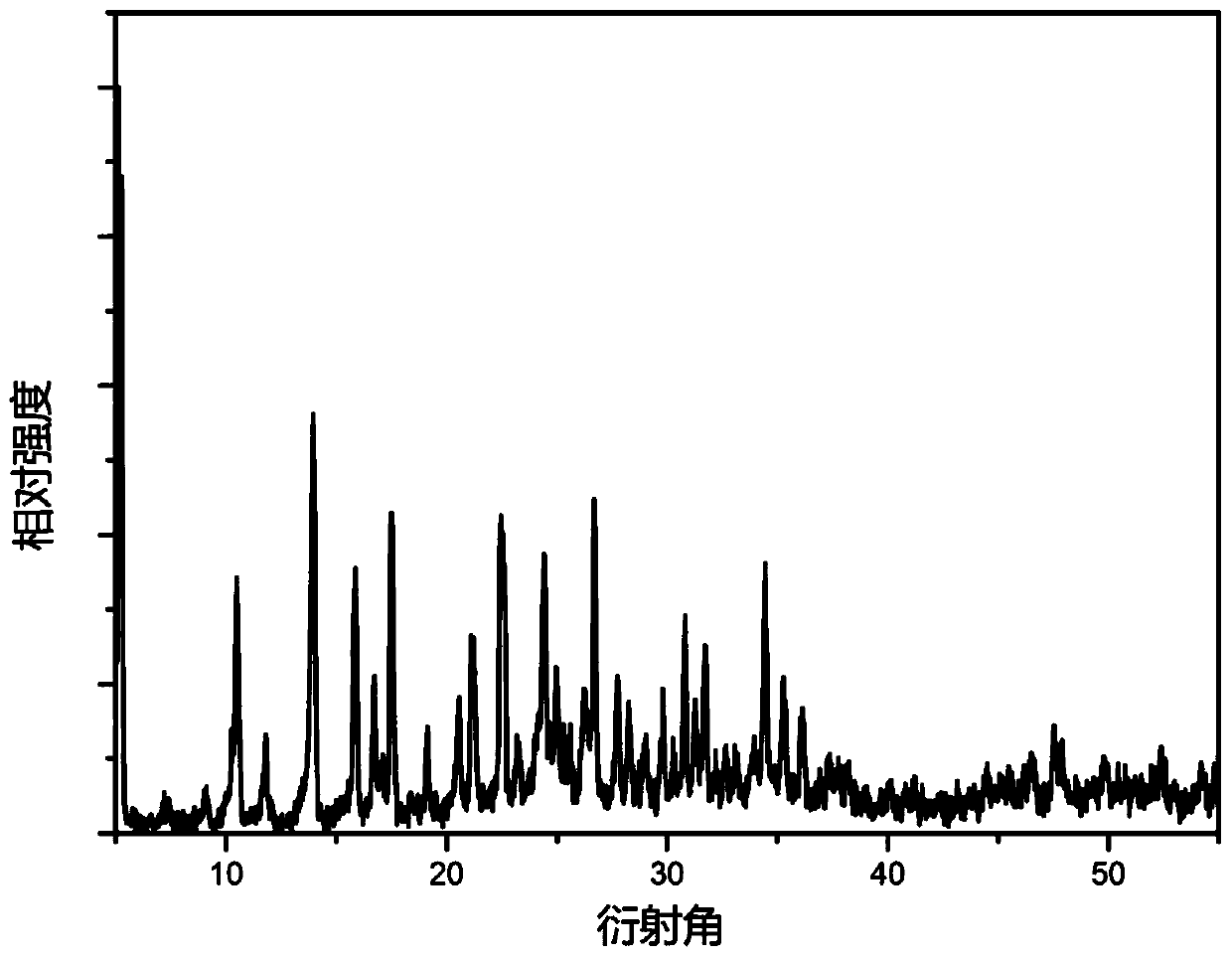

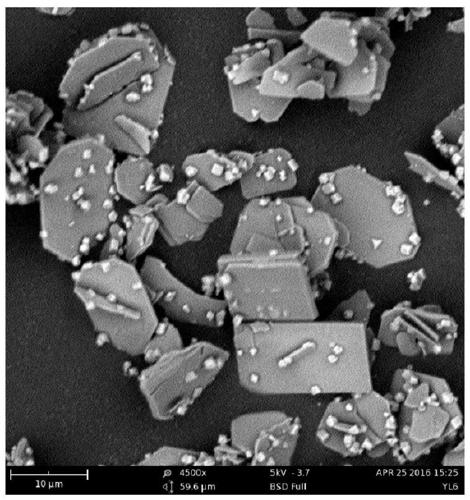

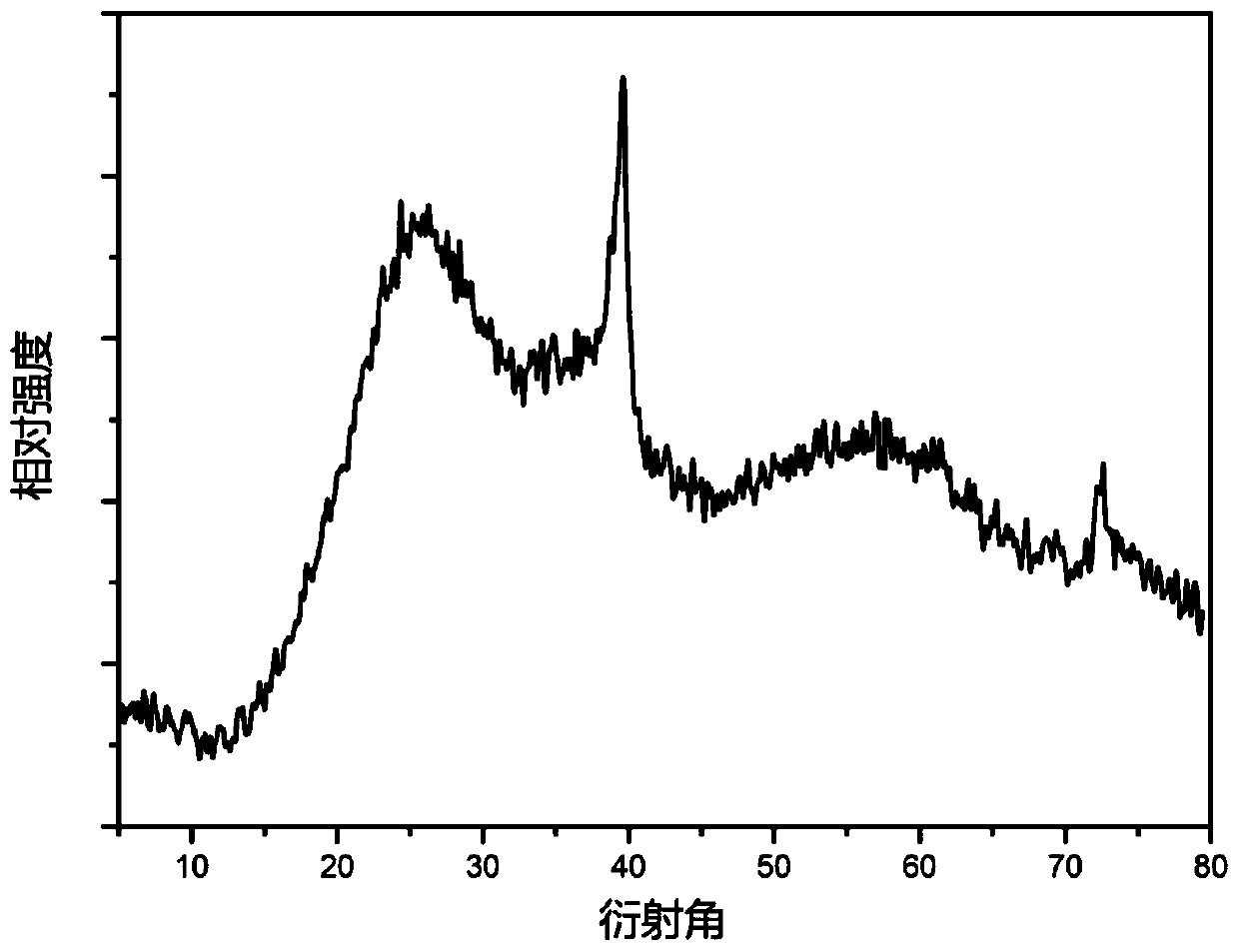

[0067] According to the ratio of zinc to tungsten molar ratio of 4:1 (1 mmol in total), zinc acetate and tungstic acid were weighed and dissolved in 4ml of N,N-dimethylformamide solution; 0.096 g of dimethylimidazole was added, ultrasonically After it dissolves evenly, pour this mixed solution into a 25ml polytetrafluoroethylene reactor, put it in an oven, and keep it at 160 degrees Celsius for 48 hours. After the reactor is naturally cooled to room temperature, there is a light yellow color at the bottom of the reactor. The precipitate was separated out, and was centrifuged and washed with ethanol several times until the obtained supernatant became colorless and transparent, and the light yellow precipitate was dried to obtain a roasted precursor. Weigh an appropriate amount of roasted precursor and place it in a roasting crucible, and place the crucible in a tube furnace. The tube furnace was evacuated with a pump, fed with high-purity argon, heated to 900°C at a heating rat...

Embodiment 2

[0076] Weigh zinc nitrate and phosphotungstic acid according to the molar ratio of zinc and tungsten being 4:1 (total 1 mmol), and dissolve in 2 ml of N,N-dimethylformamide, 1 ml of ethylene glycol and 1 Add 0.064 g of dimethylimidazole to the mixed solution composed of 1 ml of ethanol, ultrasonically wait until it dissolves evenly, put the above mixed solution into an oven at 120 degrees Celsius and keep it for 72 hours, then wait for it to cool naturally to room temperature, and put it in the bottom of the reaction bottle A light yellow precipitate was precipitated, and was centrifuged and washed with ethanol for several times until the obtained supernatant became colorless and transparent, and the light yellow precipitate was dried to obtain a roasted precursor. Weigh an appropriate amount of roasted precursor and put it in the roasting crucible, and put the crucible in the tube furnace, pump the tube furnace into a vacuum, feed high-purity nitrogen, and use 2°C / min to heat ...

Embodiment 3

[0078] Weigh zinc nitrate and phosphotungstic acid according to the molar ratio of zinc and tungsten being 4:1 (1 mmol in total), and dissolve them in a mixed solution consisting of 2 ml of ethylene glycol and 1 ml of ethanol, and add 0.064 g Dimethylimidazole, ultrasonically until it dissolves evenly, put the above mixed solution in an oven at 120 degrees Celsius and keep it for 72 hours, then wait for it to cool to room temperature naturally, a light yellow precipitate precipitates out at the bottom of the reaction bottle, and wash with ethanol several times by centrifugation, Until the obtained supernatant becomes colorless and transparent, the light yellow precipitate is dried to obtain a roasted precursor. Weigh an appropriate amount of roasted precursor and put it in the roasting crucible, and put the crucible in the tube furnace, pump the tube furnace into a vacuum, feed high-purity nitrogen, and use 2°C / min to heat up rate, to 1000 degrees Celsius, and keep it for 300 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com