Aerogel composite glass and manufacturing method thereof

A technology combining glass and manufacturing methods, which is applied in the fields of heat preservation, lighting, light transmission, heat insulation, and sound insulation materials, and can solve the problems of difficult airgel preparation, easy damage, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] The airgel composite glass was prepared by the following steps:

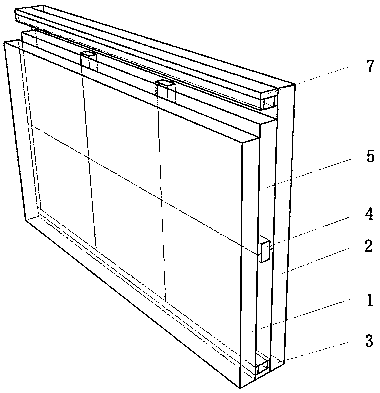

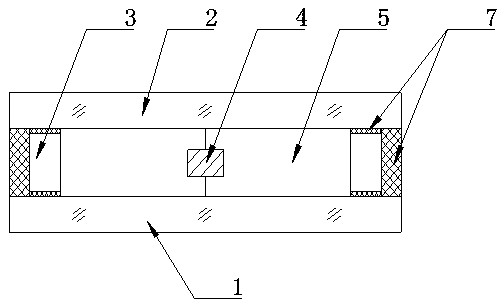

[0106] (1) Use the water glass sealant 7 to bond the lower surface of the broken bridge aluminum spacer frame 3 to a piece of float glass 2 to form a cavity with one side open, the thickness of the glass is 6 mm, and the thickness of the cavity is 6 mm;

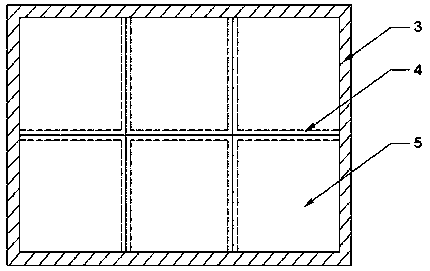

[0107] (2) Pre-install the polycarbonate spacer 4 into the concave shape between the sides of two adjacent airgel plates 5 to obtain a whole composite plate, and then place them together in the cavity, and then place the polycarbonate The end of the spacer 4 is fixedly connected on the inner surface of the broken bridge aluminum spacer frame 3 by welding; wherein, the section of the polycarbonate spacer 4 is rectangular, and the concave shape of the side section of the airgel plate 5 includes the first side 511, the second side 512 and the third side 513, one side of the second side 512 is connected with the first side 511, the other side is connected wi...

Embodiment 2

[0111] The airgel composite glass was prepared by the following steps:

[0112] (1) Use potassium silicate sealant 7 to bond the lower surface of the stainless steel spacer frame 3 to a piece of tempered glass 2 to form a cavity with one side open, the thickness of the glass is 6 mm, and the thickness of the cavity is 8 mm;

[0113] (2) Put the ultra-clear glass spacer 4 into the concave shape between the sides of two adjacent airgel plates 5 to obtain a whole composite plate, and then place them together in the cavity, and then put the ultra-clear glass The ends of the spacer 4 are fixedly connected on the inner surface of the stainless steel spacer frame by welding, wherein the section of the ultra-clear glass spacer 4 is rhombus, and the concave shape of the side section of the airgel plate 5 includes the first side 521 and the second side. Two sides 522, the first side 521 and the second side 522 are connected at a certain angle and have the same length, and the concave sh...

Embodiment 3

[0117] The airgel composite glass was prepared by the following steps:

[0118] (1) Use butyl sealant 7 to bond the lower surface of the FRP spacer frame 3 to a piece of cesium potassium glass 2 to form a cavity with one side open, the thickness of the glass is 6 mm, and the thickness of the cavity is 10 mm;

[0119] (2) Install the foam glass spacer 4 in advance into the concave shape between the sides of two adjacent airgel plates 5 to obtain a whole composite plate, then place them together in the cavity, and then place the foam glass spacer The ends of 4 are fixedly connected on the inner surface of the glass fiber reinforced plastic spacer frame 3 by welding, wherein the section of the foam glass spacer 4 is hexagonal, and the concave shape of the side section of the airgel plate 5 includes the first side 531, the second side Two sides 532 and a third side 533, one side of the second side 532 is connected with the first side 531, and the other side is connected with the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com